IXL-500

check weigher for large package

A checkweigher for large packages is a specialized weighing system designed to accurately and efficiently weigh and sort large and heavy packages in various industries, such as logistics, shipping, and manufacturing. Checkweighers are essential in quality control and logistics processes to ensure that products meet weight specifications and regulatory requirements. Here are key features and considerations for checkweighers designed for large packages:

## Features:

### 1. **High Weight Capacity:**

- Checkweighers for large packages are equipped with robust weighing systems capable of handling heavy loads, often exceeding standard checkweigher weight capacities.

### 2. **Large Weighing Platform:**

- A spacious weighing platform accommodates oversized and bulky packages, ensuring that they fit comfortably on the conveyor belt for accurate weighing.

### 3. **Durability and Construction:**

- Sturdy construction using durable materials to withstand the weight and dimensions of large packages, providing longevity and reliability in industrial settings.

### 4. **Dynamic Weighing Capability:**

- The ability to weigh packages in motion, allowing for continuous and high-speed weighing as packages move along the conveyor belt.

### 5. **Accuracy and Precision:**

- High accuracy and precision in weighing to meet regulatory requirements and quality control standards.

### 6. **Customizable Sorting:**

- Customizable sorting options to divert packages based on weight deviations, ensuring that only products within specified weight ranges continue down the production line.

### 7. **Integration with Production Line:**

- Seamless integration with existing production or packaging lines, facilitating efficient and automated weighing processes.

### 8. **User-Friendly Interface:**

- Intuitive and user-friendly interface for easy setup, calibration, and monitoring of the checkweigher system.

### 9. **Data Logging and Reporting:**

- Comprehensive data logging and reporting capabilities to track and analyze weight data over time, aiding in quality control and process improvement.

### 10. **Reject Mechanism:**

- An efficient reject mechanism to divert non-compliant or overweight packages for manual inspection or reprocessing.

### 11. **Hygienic Design (Optional):**

- In industries with strict hygiene requirements (such as food processing), checkweighers may have a hygienic design with easy-to-clean surfaces.

### 12. **Multi-Lane Capability (Optional):**

- Some checkweighers may have the capability to handle multiple lanes of large packages simultaneously, increasing throughput.

### 13. **Compliance with Standards:**

- Compliance with industry standards and regulations for weighing equipment, ensuring legal metrology requirements are met.

### 14. **Remote Monitoring (Optional):**

- Remote monitoring capabilities for real-time oversight and control, especially in large-scale industrial facilities.

### 15. **Integration with Data Systems:**

- Integration with larger data management and enterprise resource planning (ERP) systems for seamless data flow and process optimization.

## Considerations:

1. **Package Size and Weight Range:**

- Ensure that the checkweigher is suitable for the specific size and weight range of packages in your application.

2. **Environmental Conditions:**

- Consider the environmental conditions of the installation site, including temperature, humidity, and potential exposure to dust or contaminants.

3. **Production Throughput:**

- Evaluate the required throughput to ensure that the checkweigher can handle the production speed of the packaging line.

4. **Compliance Requirements:**

- Verify that the checkweigher complies with relevant industry standards and legal metrology requirements.

5. **Integration Compatibility:**

- Confirm compatibility with existing production lines and systems for seamless integration.

6. **Ease of Maintenance:**

- Consider the ease of maintenance, including accessibility for cleaning, calibration procedures, and availability of spare parts.

Selecting the right checkweigher for large packages involves a careful assessment of your specific application requirements and production environment. Manufacturers and suppliers often provide consultation services to help businesses choose the most suitable checkweighing solution for their needs.

Checkweigher IXL Series

Suitable for weight checking for packaged products, to ensure quality standards

●High speed , high sensitivity, high stability dynamic weight checking

●Easy to clean , simple to disassemble

Product Features

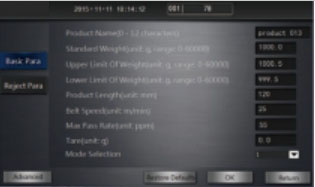

User-friendly Function

●Multi languages

●Data storage

●Large memory capacity

High Configuration

●Touch screen

●USB Port,Ethernet function

●Real time monitoring on PC

Brief User Parameter Setting

Product Specifications

Model | IXL -500 | IXL -600 | |

Detecting Range | 0.5 to 25kg | 1 to 50kg | |

Scale Interval | 1g | 5g | |

Accuracy (3o) | ±2g | ±5g | |

Max Speed | 75 pcs/min | 50pcs/min | |

Belt Speed | 60m/min | 60m/min | |

Weighed Product Size | Width | 490mm | 590mm |

Length | 700mm | 1000mm | |

Weigher Platform Size | Width | 500mm | 600mm |

Length | 800mm | 1200mm | |

Operation Screen | 7” touch screen | ||

Product Storage Quantity | 1 00 kinds | ||

Segments Number | 1 | ||

Rejecter Mode | Rejecter optional | ||

Power Supply | 220v (optional) | ||

IP Rate | IP30/IP54 | ||

Main Material | Mirror polished/sand blasted | ||

Note:

1. The technical parameter above namely s the resuit of accuracy by checking ony the test sample on the ber. The accuracy

would be attected acording to the detecting speed and product weight.

2. The detecting speed above will be affected according to the product size to be checked

3. Requirements for different sizes by customers can be fulfilled

Product Configuration