China supply Econimic metal detector for food industry

Essential metal detector for Food Industry

Metal detectors are an essential part of any food production line, and a metal detector for the food industry is no different. Metal detectors can detect everything from lead to mercury, so they're not just a simple way to check for dangerous metals—they're also an important tool for protecting your company from legal liability.

best metal detector for food manufacturing

The best metal detector for food manufacturing will have a wide range of settings that make it easy to find whatever you're looking for. It'll also have enough sensitivity to

detect even the smallest amounts of metal or other harmful substances in your products. It'll also be able to distinguish between different types of metals so that you don't accidentally contaminate something with iron ore!

A good metal detector will also be able to scan multiple items at once and provide accurate results in seconds.

A food-grade metal detector should be able to help your company avoid contamination issues while ensuring that the products you ship out contain zero trace amounts of harmful substances.

Why metal detector is nessary for food processing

If you're in the food industry, you know how important it is to keep your products safe from contamination. You also know that metal detectors can be an important part of your safety measures.

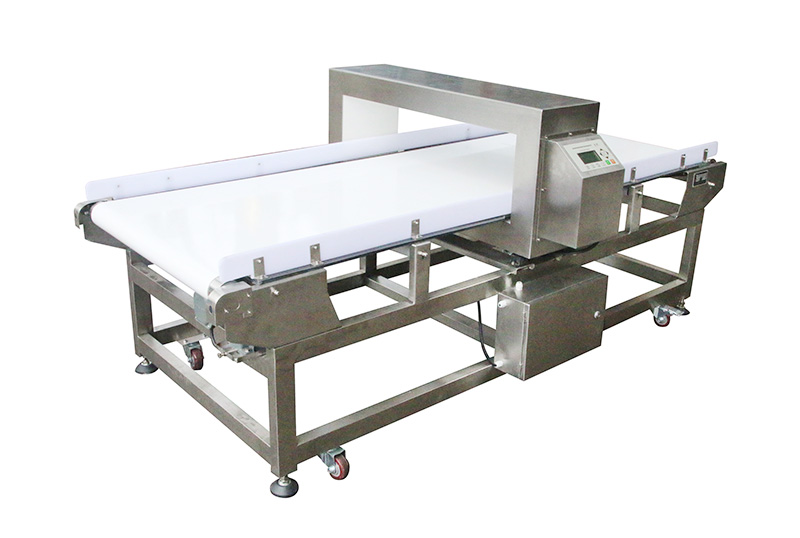

That's why we make industrial metal detectors with conveyor belt , a metal detector specifically designed for food manufacturing and processing. Our detector will help you protect against any foreign objects that might be lurking in your products, whether they're seeds or steel—or both! It's lightweight, easy to use, and incredibly reliable.

metal detector for food production line

The food industry is a highly regulated one. The FDA and other regulatory bodies ensure that food producers and processors follow strict guidelines when it comes to the quality of their products, while also ensuring that they are following all of the proper safety procedures.

As a result, producing food in a safe and sanitary manner is critical for ensuring that you stay within legal boundaries and avoid any negative health consequences that could arise from improper sanitation practices. Metal detectors are an essential part of this process; they help to ensure that only approved materials are used for the production of your products.

The best metal detector for food production lines is what you need if you want to keep your customers safe from harmful substances such as asbestos or lead particles, which may be found in some materials used in manufacturing.

metal detector for food manufacturers

Metal detectors are used in the food industry for a variety of reasons.

Food manufacturers use them to keep track of the metal content of their products, which can affect the taste, safety, and shelf life. This is especially important

when it comes to certain types of meat products that are highly processed and may have been exposed to other metals during processing.

Food processors also use metal detectors to ensure that they're only buying food items that have been properly cleaned and sterilized. This is especially important when working with meats like beef or pork that may have been exposed to bacteria or viruses during processing.

Metal detectors are also used by restaurants and grocery stores to make sure that food is free from dangerous contaminants such as lead, mercury, or arsenic.

Pharmaceutical Industry metal detector

The viking Pharmaceutical Metal Detector is no longer available for tablets or capsules.

Superior quality control industry-leading level* High Sensitivity Inspection Head and Signal Processing specialized in the inspection of pharmaceutical items significantly reduce product effect and provide high sensitivity detection.

Metal detection plays a critical role in many industries,

including food processor or pharmacy. DongGuan Viking technology co;ltd designed numerous conveyor systems with metal detection. This allows multiple ways of rejecting products.

The metal detection equipment can detect and remove ferrous, semi-ferrous, or stainless metals present in the process flow. The units can also locate metal within individual particles.

The detection and separation of metal particles is a great way to protect your processing equipment. This can help save money, reputation, and downtime. Get in touch with us to discuss your metal detector conveyor systems design.

metal detector for wood industry

Metal detector for wood working

The best woodworking metal detector is what you are looking for. This product comes in a variety of prices. We will be presenting a list affordable, but highly effective, metal detectors that can be used to detect wood. Metal detectors are very useful tools for finding old nails and coils in wood or walls. You can easily locate them and remove them so that you reduce the risk of injury while working.

You should always find the appropriate tramp metal if you are going to work with any kind of lumber. Otherwise, it could cause irreparable damage to your tools or even an accident. This can not only cause damage to your device but could also result in injury to yourself. It is important to remove any old metals or coils from the wood so that the tool can work smoothly without being damaged.

Handheld metal detectors for wood

There are three types handheld metal detectors. For security purposes, the first type is used at airports. These are not intended to detect nails, but work well with knives and guns.

The second is pinpointers. These can be used in conjunction with a standard metal detector to locate metal in the ground. They are lightweight and easy to carry. However, their depth range is limited.

The V006 is a popular choice for woodworkers. It can be used with flat boards. They cannot detect metal below the bark. They are not suitable for logs.

This hand-held metal detector can locate metal objects in wood! This 9-volt metal detector is also suitable for security personnel who need to scan for metal. It features an audio alarm, LED visual alert, low battery alert, and 50% sensitivity reduction. This hand-held metal detector is supplied with a convenient carrying case.

Metal embedded in wood?

Also can be used to scan for security issues

6 in. For one-pass coverage, use the wand

Audio alarm and visual LED alert

Button to reduce sensitivity by 50%

Standard earphone jack (earphones not included).

Low battery alert

Storage case

Metal detector for wood application

For boards, chipboard, chipboard, osb, plywood, logs, bolts, logs, trunks, pellets, planings, sawdust, shavings, chips or grindings.

Industrial sensor metal detector for wood

The best metal detectors are available for logs.

They can detect any nails, screws, steel, or iron that may be hidden in trees.

For certain reasons, nails or screws are pierced into trees to make them appear deeper.

However, the tree is not visible enough to be used as a metal detector for logs.

It's common for the saw to strike nails. If this happens, it will cost about 30 dollars to fix it.

In the worst case, it could cost you 100 dollars. A metal detector is your best option.

Not all metal detectors are capable of detecting metals in logs.

This includes viking tunnel metal detector that special design for wood and quick fast detection

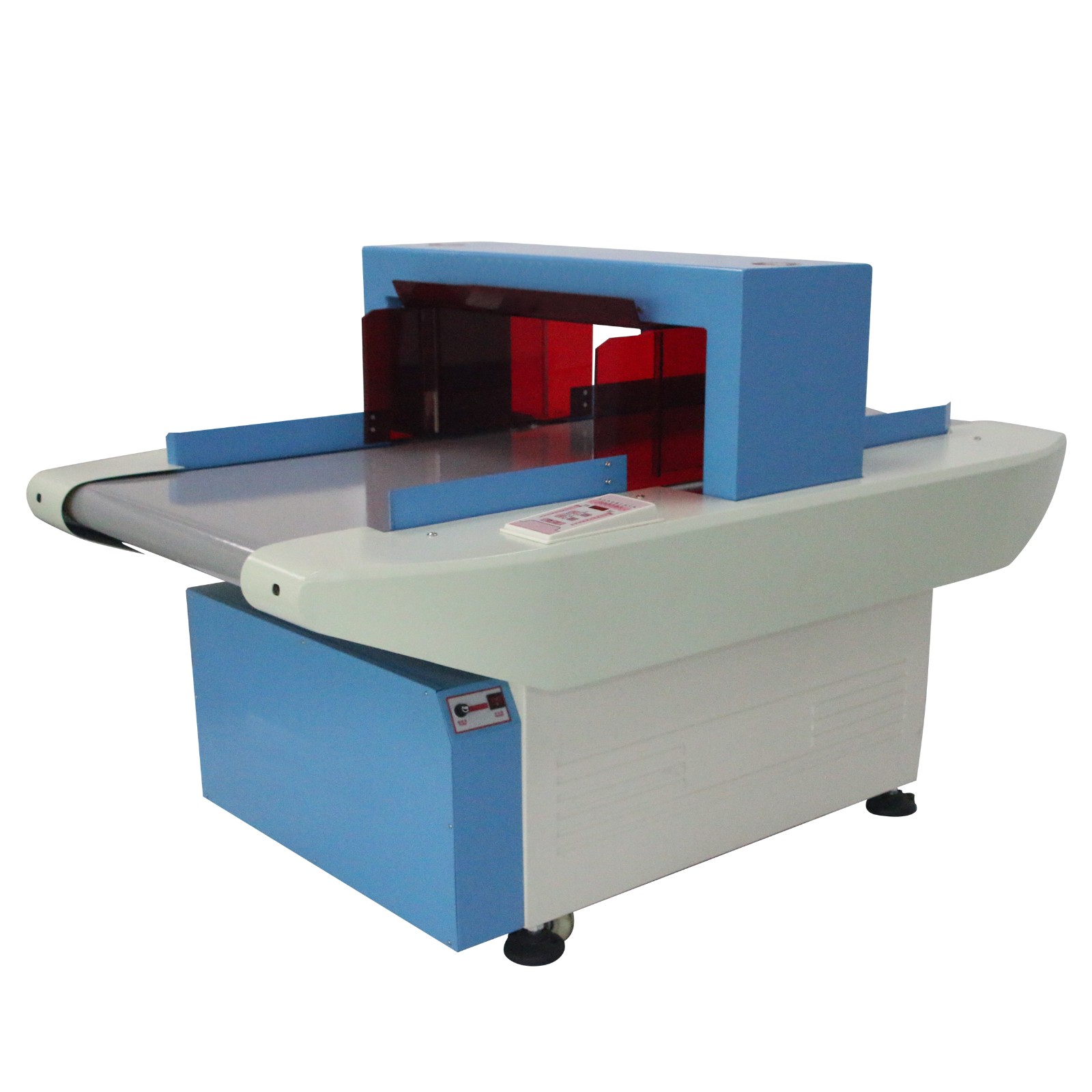

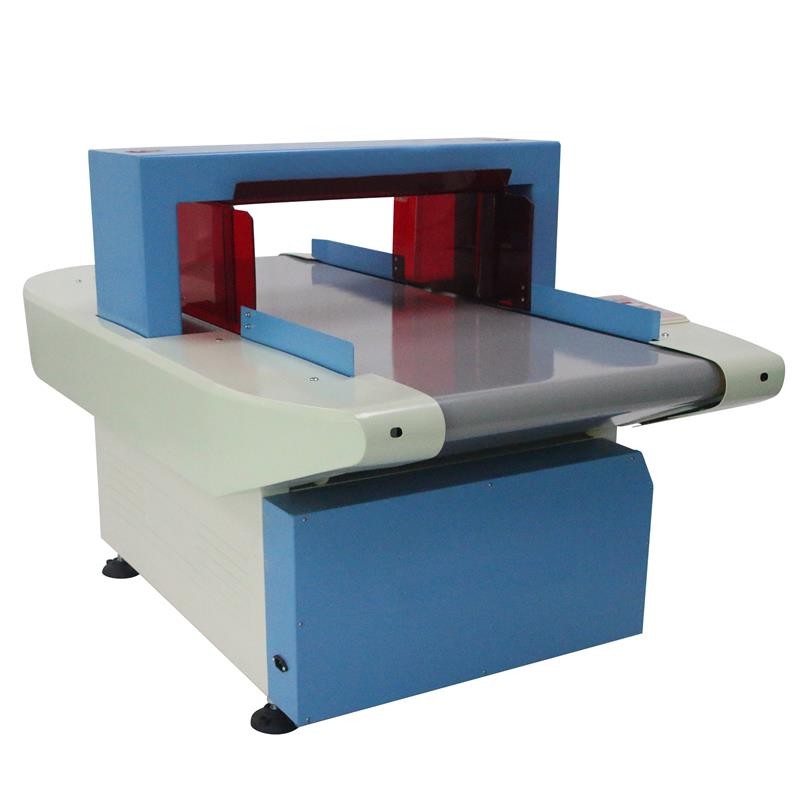

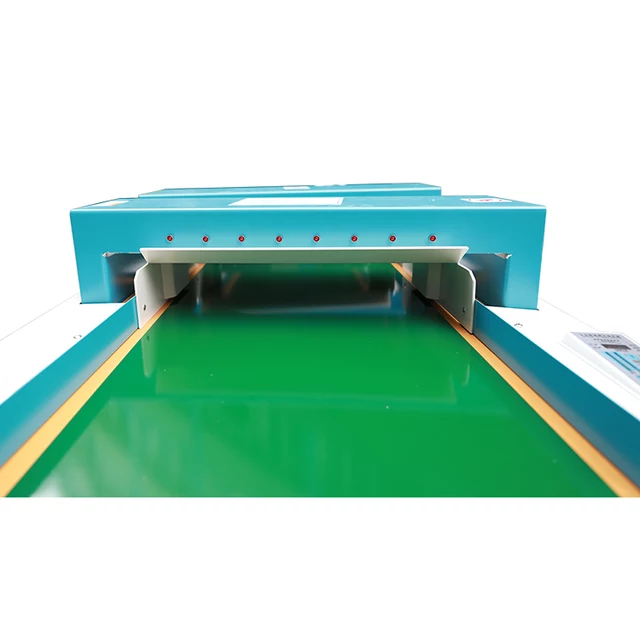

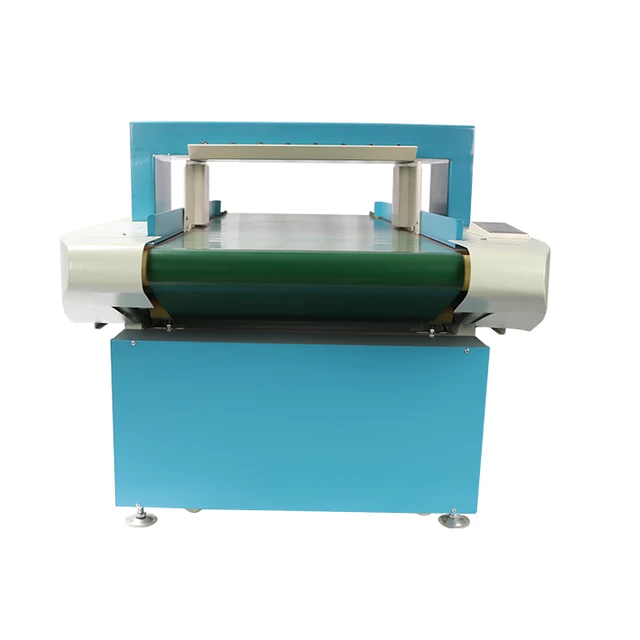

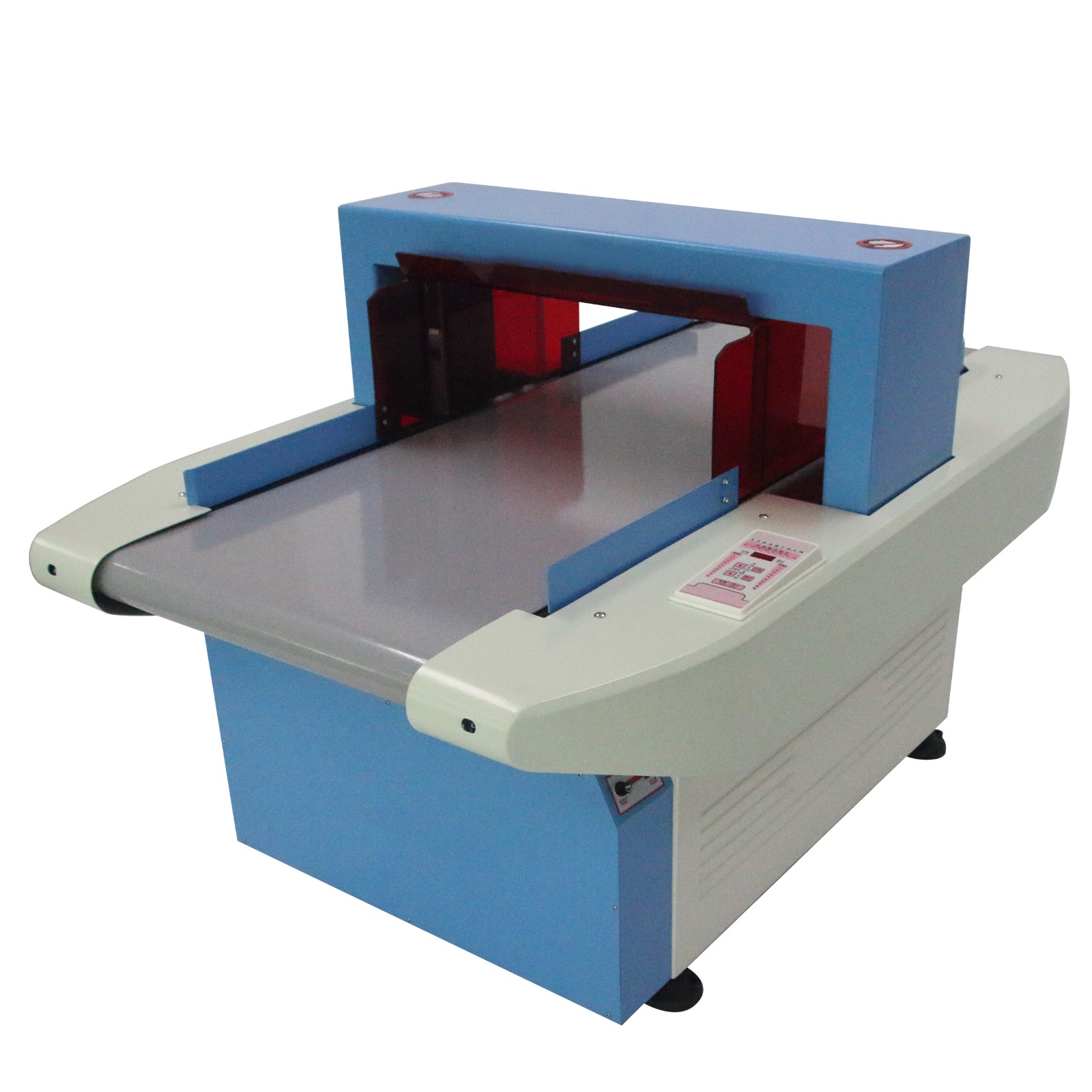

Garment and textile needle metal detector

Essential needle metal detector

This garment and textile needle metal detector is an essential tool for any sewing room. It can be used to scan for metal objects as small as a half-penny, which are commonly found in clothing and textiles.

Easy operation needle metal detector

The detector is easy to use and can be set up quickly. It has a large LCD screen that displays the results of the scan and other information such as the number of items scanned or how long ago they were scanned.

It comes with a carry case that makes it easy to transport between jobs and stores. The detector itself weighs only 1 pound and measures 9 inches by 4 inches by 2 inches tall; it’s small enough to fit into most sewing rooms or work areas without taking up too much space on shelves or counters!

The Uxcell garment and textile needle metal detector is perfect for any shop looking for a cost-effective way to protect

their products from potential damage caused by tiny metal objects like needles from stray threads or pins from loose buttons during production runs (or even just

The important role of needle metal detector in textile industry

It's well-known that metal detectors can be used for security at airports, stations, shopping centres, etc.,

but they also serve an important purpose in the food and medical industries, as well as the mining and apparel industries.

These industries use metal detectors to inspect for metal traces during quality control.

Especially in textile,garment,clothing,dress,toys,and related industries.

security walk-through and hand held metal detector

Metal detectors are the ultimate security tool. They're not just used at airports, but also in schools, stadiums, and some shops. These metal detectors can be used to detect weapons and other dangerous objects.

Today we will learn how to use a hand-held metal detector and how to walk through one.

Security walk through metal detectors

Security walk-through metal detectors are an effective way to detect metal concealed in a person's clothing.

They are also used at airports to detect any dangerous objects that may be carried onto an aircraft.

Security hand held metal detectors

Security hand-held metal detectors are used to check people for weapons before they enter a restricted area or after they leave it, as well as at checkpoints during public events such as parades or festivals.

Airport metal detectors

Airport metal detectors can be used to check passengers for prohibited items, including firearms, knives and other sharp objects which could cause injury if they are taken on board an aircraft.

Security walk-through metal detectors are a great way to make sure your company is safe. They are a handheld device that can be used to check for metal objects, such as guns and knives. They are used at airports, train stations, and other security-sensitive locations.

The security hand held metal detector is a more portable alternative to the larger walk-through variety. You can take it with you in your car or even on the bus! These devices use radio waves to detect metal objects. They look similar to walk-through metal detectors but they may be smaller or less powerful than their larger counterparts.

They are also used at airports and train stations as well as in schools, banks and other businesses that require high security standards.

Security walk through metal detector, security hand held metal detector, security airport metal detector.

In today's world, the threat of terrorism is a very real one. The threat of having your bag or suitcase searched by a hand-held metal detector is also real.

The best way to ensure that you don't have to go through any of this hassle is to hire us here at [company name]. We will do all of the work for you, so you won't have to worry about whether or not your baggage is going through the scanner correctly or what happens if your luggage is not deemed suspicious enough. You will also be able to rest easy knowing that our services are covered by DongGuan Viking technology co;ltd .

We offer these services as well:

- Airport security walk-throughs

- Handheld metal detectors

- x ray checks on bags and carry-on items

Rubber and Plastic Recycle metal detector

PlasticRecyclingEquipment With the world shifting towards "green" living,

plasticrecyclingequipment is more in demand than ever across many industries that work with the material for all types of applications. These products don't have to be thrown away. They can be shredded, melted, and repurposed in different products. Recyclingplasticis imperative in today's global climate, and Arlington PlasticsMachinery has the plasticrecyclingequipment needed to reduce any company's ecological footprint.

There are many types of plasticrecyclingequipment which reprocess plasticand make the material reusable for another product. These machines can be combined with shredders, granulators, pelletizing extrusion line and pelletizers to reduce larger pieces of plastic into smaller pieces, melt them, and then make a new product. Arlington PlasticsMachinery stocks all types of machinery, including liquid ring pelletizers, strand pelletizers and underwater pelletizers.

Metal contamination mixed into plastic recycling

But during the recycing ,there have many risk especially when metal contamination mixed into it ,such as ferrous, non-ferrous,stainless steel , nails, staple and metallic obejects , How to separate these materials from the plastic and get clean plastic it is important .

Now we developed many models of metal detector includes separator in conveyor and gravity shape that can inspection this particle and separator it by automatic rejection system

Recycled Equipment

There are many benefits of use a metal detection system during you recycling .

Recyclingplasticreduces costs and the wasteof raw materials. This directly impacts a company's bottomline. Recyclingmachinery is often more efficient and can result in higher productivity. Both of these factors influence the cost reduction. Recyclingmachinery's greatest benefit is the reduction of waste in landfills, and the negative effects on the environment. Recycling equipment can be used to recycle plastic products, making it easy to be more eco-conscious.

Here we according to our 8 years industrial experience list all the checkweigher related application

Frozen food metal detector for factory

The vikingdetector provides many options for frozen food (IQF), including vegetables, fruits, pot stickers and pizza rolls. It also offers appetizers, meat, poultry and seafood.

conveyor belt metal detector for frozen food

for use in washdown environments. They can withstand extreme temperatures and below-freezing temperatures, where condensation can form on surfaces. For easier cleaning, buckets with polygonal shapes allow for greater access to corners.

Metal detection for frozen food

DongGuna Viking technology co;ltd designs many conveyor systems with metal detection. They allow multiple methods for rejecting products.

Our metal detection equipment detects the presence of non-ferrous, iron and stainless metallics in the process flow and removes them. The units also look for metal inside individual particles.

You can save your reputation and money by successfully detecting and separating metal particles. For more information on metal detector conveyor systems, please contact us.

vikingdetector is able to detect the metal contamination and accurately weigh IQF products, without allowing frost to build up to impact weights.

The manufacturing process includes the inspection and rejection of food products for possible metal contamination. To integrate existing detection systems into production, however, some of them require line redesign. It is possible to integrate a complete system that includes high-sensitivity detection, food-safe conveying, and automatic rejection into virtually any existing facility.

There are high-speed models available. The vikingdetector metal detector and check weighters can be combined with VFFS, HFSFS or multiple-point discharge packaging machine such as tray, bowl and thermoform machines to create different package styles and sizes.

Application of metal detector for frozen food :

Frozen fruits

Frozen vegetables including mixed vegetables

IQF meats and poultry as well as seafood

IQF appetizers and finger food like pizza rolls, mozzarella sticks, etc.

More

Food industry metal detector for frozen

with some subcategories earning billions of dollars. It appeals to both desire and need. People eat food for survival, but they also enjoy it a lot. Even if you don't have the budget for 5-star meals or the time to cook complex meals, there's still delicious and easy options that are available. The frozenfoodmarket is here to help. This market has grown steadily since the 1960s, and it is expected to continue growing. Allied Market Research, Portland Oregon, published a study entitled "World FrozenFoodMarket - Opportunities and Forecasts 2014-2020", which predicted that the global frozenfoodmarket would reach $306 billion in 2020. The ready-to-eat market, also known as "The ready-meals market", is the largest segment of all ready-to eat food and will account for $112.7 billion of global sales. 72% of this revenue will be from North America and Europe, with the rest coming from developing markets. However, this time period is expected to bring significant growth in sales and customer demand.

Frozenmeals account for the largest share of the total sales value in the ready-meal market. Because of their long-lasting nature, and the freedom it affords consumers, frozenmeals will continue to be a leader in ready meals. This trend is expected to grow. The business and food-serviceindustry, and fast-foodrestaurants in particular, have been a staple of Western culture fordecades and there is an increasing reliance on these restaurants formeals and this trend is seeing rapid growth in developing markets across the world. These developing markets are being led by many Asian and African countries, as the North American and European foodservice industries are supplementing the European and North American markets. Due to the increase in pre- and semi-cooked foods, it is expected that 35% of this market's sales will be in Asia Pacific, Europe, Africa and the Middle East by 2020.

Due to our increased reliance on frozenfoods, healthy frozenmeals and snacks have been growing in popularity over the past few years. Organic soups, organic fries and other healthy snacks are in high demand from consumers. Frozenfruits and veggies still make up about 14% of total revenue in the frozenfoodmarket. The desire to find healthier alternatives will eventually spread to developing countries.

A market as vast as frozenfoods presents a problem. How can we regulate it and make sure that the consumer is safe? While each country has its own rules about what can be sold for consumption and what ingredients must be modified, there are some things that all countries agree on. This is also true for metalfragments. Although it may sound odd to some, the industry is fighting against metalfragments every day. Automation is becoming a key component of the ready-meal market. The food comes in direct contact with machines throughout its lifecycle, from raw ingredients to transport to processing to packaging. FoodGrade MetalDetectors have been developed by the industry to eliminate this risk. They can detect any food fragments that could possibly cause harm to the consumer.

These industrial metaldetectorsbenefit everyone involved. They are there to protect consumers from any harm. In addition, they provide financial and reputation insurance. Grocery Manufacturer Accusation published a 2011 study showing that 58% of food companies had suffered at least one recall over the past five years because of potentially dangerous foreign objects in their packaging. These recalls can be costly and lead to a change in the public's perception of the company.

Common industrial metal detector for frozen

The two most common categories of industrial metaldetectors for the frozenfoodindustries are: A system that relies on a general-purpose head is the more common. This type can detect almost any type of fragment in frozen and non-frozen products. This second type of metaldetectors has systems that use a ferrous-in foil search. These systems are limited in their ability to locate magnetic metals within foil-wrapped new products. These detectors are very effective in what they can do. The company needs to know how to locate the best detector for their product. All of this is done to protect consumers in an industry that is rapidly expanding.

Combo metal detector and check weigher for meat processing

The Combo Metal Detector and Check Weigher for Meat Processing is a great tool for the meat processing industry. The combi weigher offers you the ability to check your product weight with ease and accuracy, while at the same time detecting any metal objects in the meat that could cause contamination issues.

This particular combi weigher has been designed with a stainless steel frame and ABS plastic parts, which means it is both durable and long lasting. It also comes with an adjustable stand so that you can place it conveniently wherever it needs to be placed on your production line.

Metal detectors and check weighers

Metal detectors and check weighers are used to identify and check for metal objects in meat. The metal detector is a device that emits high-frequency sound waves that are reflected off of the surface of an object. The check weigher then detects the reflected sound waves and compares them to a set threshold value. If there is more than the threshold value, then the object is considered to be metal.The vikingdetector metal dettector and check weigher can detection and weigh meat, including large pieces, diced, shredded, and large bulk products.

Combination weighers and detectors are also available in high-speed versions.

They can be used with VFFS, HPFS or multiple-point discharge packaging machines like tray, cup, and thermoform machines to create different package sizes and styles. Hygienic washdown weights will help you to maintain the sanitation standards required in the food industry.

When paired with a combination scale, the vikingdetector combined metal detector and weigher is an ideal solution for filling trays and single-serve snack trays with meat-snack products.

vikingdetector metal detector combo can weight:

Jerky

Shredded meats

Diced meats

Cubed meats

Beef sticks

Pepperoni

More

Conveyor metal detector for meat processing

The conveyor metal detector is a simple and effective tool for detecting the presence of metal in meat. The device also has several other applications, including detecting the presence of magnetic materials, such as iron or steel.

The conveyor metal detector can be used in a variety of industries, including food processing, pharmaceuticals and biotechnology research.

Meat processing is a complex process. There are many moving parts, and it can be difficult to keep track of what's going on in the meat industry. Whether you're a new meat processor or a veteran of the business, we've got you covered.

Our conveyor metal detector helps you monitor your meat products while they're being processed. It has been designed to prevent contamination and ensure that your product is as clean as possible.

Metal detector is a device used to detect the presence of objects on conveyor belts. Metal detectors are used in several industries, including food processing, mining, and manufacturing.

Metal detectors are also used for security purposes in airports, malls, and other public places.

A metal detector is a machine that continuously monitors the area near or underneath it. The machine uses electromagnetic waves to detect any metal objects in its range.

Metal detectors are commonly used in factories and warehouses to find items that might be dangerous or valuable. They are also used by soldiers during war time to find enemy soldiers. It is also used by police officers to find illegal weapons on suspects while they are being arrested; this helps them prevent any accidental shootings from happening while they're trying to take someone into custody!

Dynamic checkweigher for meat processing industrial

In motion checkweigher for meat processing

The in motion checkweigher is an industrial solution for handling different types of products. It can handle a variety of shapes, sizes and weights with ease. The machine is driven by an electric motor and it has a front loading design which allows easy access of the product. This model is ideal for any kind of processing industry that uses different types of materials and shapes.

Checkweigher for meat processing industrial, in motion check weigher, check weigher machine, weight checker

We are a professional manufacturer of Checkweighers in China

. We have been specialized in producing checkweighers for many years. Our products are widely used in the food industry and other fields. They can be found in many supermarkets, department stores and other places.

Metal detector for nuts and dried fruit processing

wide use of metal detector in dried fruit

vikingdetector provides combination metal detector and checkweigher for nut equipment for a variety of nuts, dried fruit, and trail mix applications. All sizes of packaging are available, even bulk boxes. metal detector and checkweigher can be used with any premade bag, tray or cup, tub, jar and bowl lines, as well as VFFS/HFFS for different packaging styles. There are a variety of discharge options available: single, twin, and multiple-point.

Food inspection is an integral part of any manufacturing process. Some existing detection solutions will need to be redesigned in order for them to be integrated into current production. This complete system includes high-sensitivity detection combined with food-safe conveyancing and automatic reject. It can easily be integrated into most existing facilities.

Washdown models are easy to clean and maintain production sanitation standards. For delicate products such as whole cashews or shelled walnuts, fragile handling features can be used.

Dried fruits and nuts safety metal detector

The metal detector for nuts and dried fruit processing is a device that detects the presence of metal fragments in products. The metal detector is used to ensure that food products are safe for consumption. It can be used in places where nuts and dried fruits are processed.

viking's blending program allows for complete metal detection control over individual components and total package weight.

vikingdetector metal detector and checweigher can use :

Dehydrated fruit

Freeze-dried fruits

Shelled nuts

Unshelled nuts

Mixed nuts

Nut flours

Almonds

Pistachios

Cashews

Sunflower seeds

Raisins

Craisins

Dried mango

Dried beans

More

ReadyTo Eat Food MetalDetector

A wide range of standard aperture sizes areavailable,suitable forreadyto eat food products application the machines are customized as per product application requirement. There are many models available to suit different products. Combine with IP 65 grade control panel forcomplete protectionagainstdust and moisture.

Metal detection is essential in many industries like food processing, or pharmaceuticals. DongGuan Viking technology co;ltd have designed many conveyor systems that include metal detection. These systems allow multiple ways to reject products.

The equipment detects and removes non-ferrous, ferrous and stainless metals within the process flow. Additionally, the units detect metal in each particle.

Your organization's reputation and money will be saved by the successful detection and separation metal particles. Call us now to talk to an application engineer and get started on your metal detector conveyor design!

There is a large demand for ready-to-eat meals in Germany. Each year, around 45 kg of frozen foods are consumed by each person. In such a high-turnover marketplace, there can't be any product inspection errors. A food recall is necessary if foreign bodies are found in ready-to-eat foods. Every year, there are approximately 2,500 food recalls across the EU. Our innovative inspection solutions can help you protect yourself from this risk.

Metal detector for fresh food processing

Metal Detector For Fresh Food Processing is a high-speed, high-precision metal detector designed to meet the demands of the food industry. It is ideal for detecting metal in fresh produce, fish and seafood, meat, poultry and other food products. The range of applications for Metal Detector For Fresh Food Processing includes:

applications for Metal Detector For Fresh

1. Checking for the presence of metals such as lead and mercury in meat, poultry and other food products;

2. Detecting the presence of metals such as iron in seafoods;

3. Detecting metals such as copper or zinc in vegetables and fruits;

4. Identifying foreign objects by scanning through packaging materials;

Fresh food safety metal detector

Ensure safety of fresh food

A metal detector is an effective tool to ensure the safety of fresh food. Food is one of the most important commodities in our daily life, and it is also one of the most expensive commodities. Therefore, it is necessary to provide reliable product quality control at all times.

Metal objection inspection

A metal detector can be used to detect any metal objects on the surface of fresh food, including metal pins, needles, nails and other sharp objects. Metal detectors are widely used in many industries such as food packing plants, livestock farms and supermarkets. They can be used as an effective tool to improve food safety.

In fact, a metal detector can also be used in other industries such as mine detection or archeology site exploration.

Food industrial metal detection standard

The metal detection standards food industry is a growing area in the food industry. The metal detection standards food industry is a growing area for the food industry. There are many different ways to detect metals in foods, including but not limited to: x-ray fluorescence spectroscopy (XRF), magnetic resonance imaging (MRI), gas chromatography (GC) and transmission electron microscopy (TEM).

The FDA has set high standards for the detection of metals in foods. These standards must be met by all companies who wish to sell their products in the United States. If you have any questions regarding this topic or would like to discuss your company's needs with us, please contact us today!

Metal detection standards are used in the food industry to ensure that your products are safe for consumption.

Metal detectors are used to detect whether or not a product has any detectable amount of metal in it. If a product has detectable amounts of metals, it can be harmful to consumers and will not be sold on shelves. In order to prevent this, metal detectors are used to check for the presence of metals in foods before they go on sale.

Food grade metal detectors are the most commonly used type of detector for this purpose, but there are other types available as well. FDA-approved metal detectors are also available for use by companies who want to be sure their products meet all government regulations regarding their safety.

Metal detection standards are used by the food industry to ensure that metals are not being used in the manufacture of food. Metal detectors can be used to test a product and ensure that it has not been contaminated with metal. Metal detectors are also used to test whether or not products contain harmful substances, such as heavy metals and toxins.

A metal detector is an instrument that uses electromagnetic waves to detect the presence of metals in a substance. It works by sending out waves through a substance, which will be reflected by any metal particles in the substance. The greater the distance between two objects, the more energy is needed to send out those waves, which means that larger objects would require more power than smaller ones so that they could be detected by the detector at longer distances.

Food grade metal detectors are designed specifically for use in food manufacturing facilities, where they can be used to screen incoming materials before processing begins. Food grade metal detectors are designed to detect all types of metals with minimal interference from other substances such as plasticizers or acids.

Metal detection standards are used by food industry to ensure the safety of their products.

Metal detectors are used to check the quality of food items before they are sold in markets or consumed by consumers. The metal detectors are used to detect any metal objects, such as coins, nails, pins and other metallic objects in food. The metal detectors come with various features like frequency range, sensitivity and reliability which play important roles in determining the performance of these devices.

The Food and Drug Administration (FDA) has passed a set of rules that require restaurants, grocery stores and other food retailers to use metal detectors when checking the quality of their products before selling it to customers. This is done in order to prevent any kind of contamination that may occur due to the presence of metals in foods.

Conveyor belt metal detector food grade

Conveyor belt metal detector, food grade metal detector, conveyor metal detectors,

Conveyor belt metal detector for food processing

Conveyor belt metal detectors are used to detect the presence of metals in food or beverages through the use of a magnetic field. This is an important tool for ensuring that the product is free from contaminants and contaminants. This can be used in restaurants, retail stores and industrial settings.

The conveyor belt is attached to a motorized belt that moves up and down along a horizontal track. The belt has several coils on it that create a magnetic field when electricity passes through them. When a metal object comes into contact with this field, it sends out an electrical signal that can be detected by your device.

Conveyor belt metal detectors are a great way to keep your food safe. These metal detectors can be used in many different industries, including food production and storage.

Food safety metal detector

In food production, conveyor belt metal detectors help you ensure the quality of your products by detecting foreign objects such as knives or needles that may be present in your products. In addition to detecting foreign objects, they also help you prevent cross-contamination between foods on the line so that you don't end up with someone getting sick from eating contaminated food.

Because these machines are designed specifically for use in food processing facilities, they're made of FDA approved materials that will not harm or damage your produce or other items being processed. They are also dishwasher safe which makes cleaning them easy after each shift or day at work!

Metal Detector for Rugs Recycling Industry

Metal Contation in rugs recycling

The metal detector is a sweep-type detector that can detect any type of metals found in a recycled rug. The metal detector is mainly used to find iron, steel and aluminum in rugs.

The metal detector can be used to recycle rugs by separating the rugs into different categories according to their composition. The metal detectors are used to identify the composition metals of rugs and separate them into different categories such as ferrous, non-ferrous, zipper, nails and so on

Metal Detector for Rugs Recycling Industry

Metal Detector for Rugs Recycling Industry is a best-selling product of Metal Detectors. It is used to detect and remove the metal objects from the rugs. The metal detector has a high sensitivity level that helps detect even the small metal objects in your rugs. It is highly effective in removing all kinds of metals like stainless steel, copper, aluminum and other metals from rugs. The metal detector will be able to detect all kinds of metals including coins, jewelry, and other items that can be found in your rug.Then connection a automatic rejection system reject it

Metal Detector for Rugs Recycling Industry has been designed to be used by both professionals and amateurs. It comes with two different types of detectors; one is a handheld metal detector while another is a wall mounted model. The handheld detector works just like any other metal detector but it has a smaller capacity than its wall mounted counterpart which makes it ideal for home use or backyard environments where space isn't an issue.

Types of metal detector suitable for rug industry

Metal Detector for Rugs Recycling Industry has been designed to be used by both professionals and amateurs. It comes with three different types of detectors; one is a handheld metal detector while another is a wall mounted model. The handheld detector works just like any other metal detector but it has a smaller capacity than its wall mounted counterpart which makes it ideal for home use or backyard environments where space isn't an issue.

Hand held metal detector for rugs

This suitable for the small capacity rug recycling industry, but fast and simple

Metal detector sensor for rug recycling line

This metal detector is a tunnel metal detector only with search head it can connection or built in you avaliable recycling machine install on the conveyor belt

Conveyor metal detector for rug recycling

This type is a customized metal detector by Dongguan Viking , we can design and suggest according to you recycling equipment size ,then drawig a CAD for you

confirm on you avaliable equipment we can customized different types of rejection system that suitable for you rug recycling need , This metal detector can detect

all kinds of metals

Food garde metal detector for bakery industry

metal objects detected metal detectors

Metal detectors are used to detect metal objects in the bakery industry. Metal detectors are used to detect metal objects in the bread producing industry,

especially when it comes to pipes and metals that can corrode or rust. This type of detector is also used to find wires and other electrical materials that may cause a fire hazard.

metal detector connect line of commerical bakery

Our full models of food grade metal detector can connect the line of commercial bakery equipment remains unmatched in terms of quality,

which ensures ideal performance and efficiency in your bakery. Our bakery metal detection machines and unrivaled industry-wide experience, will streamline your production and lower operating costs dramatically. Whether you are producing breads, pastries, cookies, pastas, or specialty products you can rest assured that we can deliver the results you require to grow your business. Our goal is to provide our commercial bakery equipment solutions to our clients at the lowest possible costs while maintaining only the highest levels of performance and support.

unpackaged food safety metal detectors

Metaldetectorforthebakryindustry is a tool that can be used to protect the integrity and safety of many unpackaged, packaged, or bulk bakery,bread It identifies metalcontaminants in packaging or processing and helps to ensure that they don't enter the bread we eat. Especi eat.It can can connect your Automatic Divider/Rounders moulder or proofing system .

Food regulation metal detector

Metaldetection systems are part of HACCP programs and can be used to ensure compliance with foodsafety regulations (GFSI. BRC. IFS. Retailers' code of conduct. Legislation. Industry guidance.

metaldetectors in

Metal detector for Bakery & Dough Proofing Equipment

What is Proofing?

Proofing is the final rise of the shaped bread before baking. It is also known as fermentation. To ensure consistent products and baking times, commercial bakeries use proofing equipment. Our technology controls the quality and speed of fermentation.all these structure are stainless steel structure or other materials,This step have the risk of metal contamination fall in,Then increase a

metal detection system after the profing is very necessary ,our detector conveyor system can combine or connect with proofing system after it is ready it can inspect the metal particles inside

then transfer into next step

It can added or conect below

Metal detector for Proof boxes - Caster Rack and Mono-Rail Automatic Traveling Rack

Metal detector for Final Tray Proofers – Floor Mounted and Overhead

Metal detector for Final Proofers - Pita Bread And Pizza Shells

Metal detector for Final Tunnel Proofers – Danish, Buns and Bread

Spiral Conveyor Proofer

Parts - All replacement parts for existing Chubco proofers

Metal detector for bread processing

Metal detector for bakery industry

Metal detector is a machine used to detect the presence of gold or silver in the flour. It is also used to detect other precious metals, such as platinum and uranium. The metal detector works by sending out an electrical current through the flour which causes it to create an electrical field that can be detected by the machine.

The metal detector is used in bakery industries to help detect any metals in the flour before it is added to a production line. It helps prevent accidents from occurring during production by making sure that no harmful elements are present in the product being produced before it goes into the hands of consumers.

Metal detectors are an essential tool for keeping your bakery safe, but they can be hard to find.

Bread production is a high-risk industry, with metal detectors used to make sure that the bread being produced is free from the potential risks of dangerous metals like lead. Metal detectors are also used in other industries such as pharmaceuticals and chemical plants, but these applications require different types of scanners and equipment than those used by bakers.

Precision Metal Detectors for the Cement Industry: Enhancing Safety and Product Quality

Overview

Explore our specialized metal detectors tailored for the cement industry, providing advanced solutions for safety and quality assurance. Our precision metal detectors are designed to detect and eliminate metal contaminants, ensuring the integrity of your cement products.

Key Features

- **Heavy-Duty Construction:** Built to withstand the rugged environment of the cement industry, our metal detectors feature heavy-duty construction for durability.

- **High Sensitivity:** Achieve high sensitivity in metal detection to identify even minute metal particles in the cement production process.

- **Continuous Monitoring:** Ensure continuous monitoring of raw materials and finished products, minimizing the risk of metal contamination.

Applications

- **Raw Material Inspection:** Thoroughly inspect raw materials for metal contaminants before they enter the cement production process.

- **Final Product Quality:** Enhance the quality of finished cement products by implementing metal detectors in the final inspection phase.

Benefits

- **Safety Assurance:** Prioritize the safety of your machinery and final products by preventing metal contamination in the cement manufacturing process.

- **Reduced Downtime:** Minimize downtime and maintenance costs associated with metal-related issues through proactive metal detection.

Why Choose Our Metal Detectors for the Cement Industry?

- **Industry-Specific Solutions:** Our metal detectors are specifically designed for the challenges of the cement industry, ensuring optimal performance.

- **Customizable Parameters:** Tailor the metal detection parameters to meet the unique needs of your cement production process.

- **Reliability:** Rely on our metal detectors for consistent and reliable detection, contributing to a safer and more efficient manufacturing environment.

Conclusion

## Elevate Safety and Quality in Cement Production with Our Precision Metal Detectors

Choose our advanced metal detectors to enhance safety and product quality in the cement industry. With heavy-duty construction, high sensitivity, and continuous monitoring, our solutions are crafted to address the unique challenges of metal detection in cement manufacturing. Prioritize safety and reliability with our industry-specific metal detectors.