TXE-1815 Advanced X-ray Technology in Food Industry

Elevate Food Safety Standards with Advanced X-ray Technology**

In the ever-evolving landscape of food safety, our advanced X-ray technology takes center stage, redefining the parameters of Quality Assurance for Food Products. This product introduction sheds light on the cutting-edge features and innovations that set our solutions apart in the food industry.

Precision Screening for Unparalleled Quality Assurance**

Our X-ray inspection systems bring precision to the forefront of food safety. Quality Assurance for Food Products is not just a promise; it's a commitment to thorough screening using advanced X-ray technology. With precision as our guiding principle, we ensure unparalleled quality assurance in every step of the food manufacturing process.

Setting New Standards in Food Safety and Integrity**

In an industry where safety and integrity are paramount, our solutions rise to the occasion. By incorporating advanced X-ray technology, we set new standards for Quality Assurance in the food industry. The comprehensive screening guarantees the purity of food products, reinforcing our commitment to maintaining the highest quality and safety standards.

Cutting-Edge X-ray Inspection Solutions for Food Quality Control**

Our X-ray inspection solutions represent the cutting-edge of technology in food quality control. The seamless integration of innovative features ensures that each product undergoes rigorous screening, adhering to the most stringent quality control measures. Elevate your food quality control protocols with a solution designed to exceed industry expectations.

Confidence in Food Manufacturing Processes**

Confidence in food manufacturing processes is non-negotiable. Our advanced X-ray technology instills trust in every step of the production line. From contaminant screening to quality assurance, our solutions provide the assurance and confidence needed to deliver high-quality and safe food products to consumers worldwide.

Purity Assurance and Innovation in Food Safety**

Purity assurance and innovation go hand in hand in our approach to food safety. Our solutions bring innovation to the forefront, ensuring that the purity of food products is maintained at the highest level. With state-of-the-art technology, we redefine the landscape of food safety, providing manufacturers with the tools needed to stay ahead in an ever-changing industry.

Thorough Contaminant Detection for Unrivaled Food Quality**

Thorough contaminant detection is at the core of our Quality Assurance for Food Products. Our X-ray inspection systems go beyond conventional methods, identifying contaminants with exceptional accuracy. This emphasis on thorough screening guarantees unrivaled food quality, positioning our solutions as indispensable assets in the quest for excellence in the food industry.

In conclusion, our Advanced X-ray Technology for Quality Assurance in Food Products is not just a product; it's a transformative force in the pursuit of excellence and safety. From precision screening to setting new standards in food safety, our solutions represent the pinnacle of innovation. Elevate your food manufacturing processes with confidence, knowing that our advanced X-ray technology is safeguarding the quality and integrity of your products at every turn.

X-ray Inspection System takes advantages of the penetrating power of X-ray to detect contamination. It can achieve

a full range of contaminants inspection including metallic, non-metallic contaminants (glass, ceramic, stone, bone,

hard rubber, hard plastic, etc). It can inspect metallic, non-metallic packaging and canned products, and the inspection

effect will not be affected by temperature, humidity, salt content, etc.

Product Features

Simple to Disassemble, Easy to Clean, and Reliable Security

●Good environment adaptability

●Equipped with industrial air conditioner

●Completely sealed structure to avoid dust

●Environmental humidity can reach 90%

●Environmental temperature can reach -10 to 40°C

Excellent Product Applicability

●up to eight grade image processing technology to achieve the best product adaptability and stability

Shielding Function

●cans shielding

●Desiccant shielding

●Boundary shielding

●sausage aluminum buckle shielding

High Configuration of Hardware

●Spare parts are well-known imported brands to ensure the performance and service life of the machine

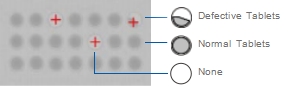

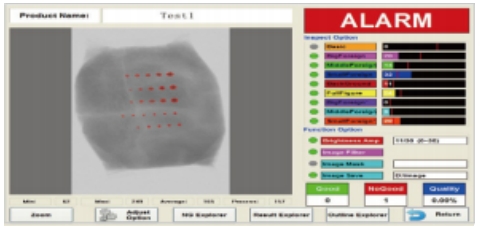

Defects Inspection Function

●The system will detect and inform tablet crack, tablet lacking and tablet with contamination

Excellent Operability

●15-inch touch screen display, easy to operate ,

●Auto-learning function. Equipment will automatically remember qualified product parameters

●Automatically save the product images , which is convenient for user's analysis and tracking

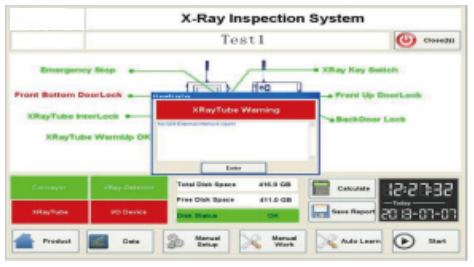

Comprehensive and Reliable Security

●X-ray leakage meets FDA and CE Standards

●perfect safe operation. monitoring to prevent the leakage from mis-operation.

Compact Economical X-ray Inspection System

●Competitive price

●Good sensitivity and stability

Product Specifications

Model | TXE-1815 | TXE-2815 | TXE-3815 | |

X-ray Tube | MAX 80W/65KV | |||

Inspection width | 180mm | 280mm | 380mm | |

Inspection Height | 150mm | |||

Best Inspection Ability | stainless steel ball Φ0.5mm stainless steel wire Φ0.3*2mm Glass/ceramic ball Φ1.5mm | |||

Conveyor Speed | 5 to 90m/min | |||

O/S | windows 7 | |||

Protection Method | soft curtain | |||

X-ray Leakage | <1uSV/h | |||

IP Rate | IP54 (IP65 optional) | |||

Working Environment | Temperature | -10 to 40°C | 0 to 40°C | |

Humidity | 30~90%, no dew | |||

Cooling Method | Industrial air conditioning | |||

Reject Mode | sound and light alarm, belt stops (Rejecter optional) | |||

Air Pressure | 0.8MPa | |||

Power Supply | 0.8kW | |||

Main Material | SUS304 | |||

Surface Treatment | Brushed SUS | |||

Note:

The technical parameter above namely is the result of sensitivity by inspecting only the test sample on the belt. The actual sensitivity would be affected according to the product being inspected.

Product Configuration