Reliable Metal Detection for Garment Products

What are Metal Detection Systems for Garment Products?

In garment production, it's important to ensure the safety and quality of your products. One way to do this is by implementing metal detection systems. These systems use advanced technology to detect any metal contaminants in your garments, ensuring that your products are safe for customers to wear.

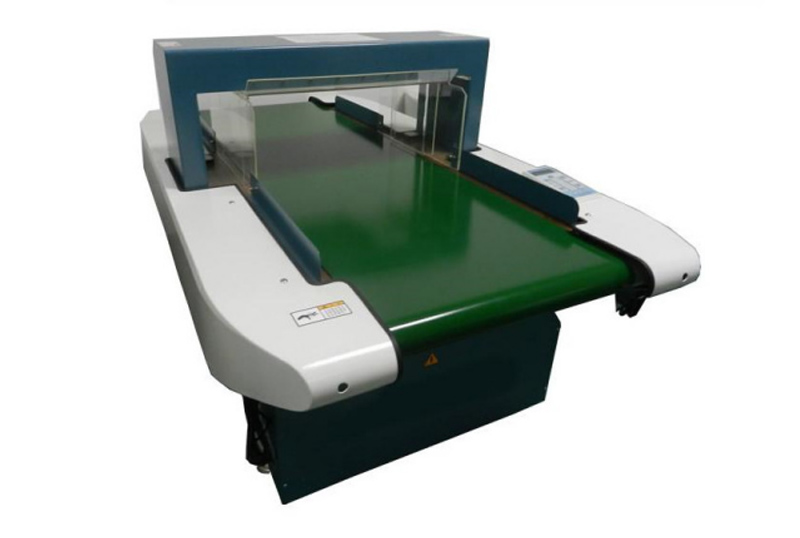

Metal detection systems typically consist of a conveyor belt or other type of material handling system that moves garments through a detection tunnel. Inside the tunnel, a metal detector uses advanced technology to scan the garments for any metal contaminants. If a metal object is detected, the system will alert the operator and automatically remove the contaminated garment from the production line.

The Importance of Metal Detection in Garment Production

Implementing metal detection systems in your garment production process is essential for several reasons:

Safety: Metal contaminants can pose a serious safety risk to customers if they go undetected. By using metal detection systems, you can ensure that your garments are free of any metal objects that could cause harm.

Quality control: Metal contamination can also cause quality issues in your garments. For example, a small metal object could create a tear in the fabric, resulting in a faulty product. By detecting and removing metal contaminants, you can ensure that your garments meet your quality standards.

Compliance: Many industries have regulations regarding metal contamination in products, and failing to comply can result in legal issues and damage to your brand reputation. Implementing metal detection systems can help ensure compliance with these regulations.

Choosing the Right Metal Detector for Garment Manufacturing

When choosing a metal detector for garment manufacturing, there are several factors to consider:

Sensitivity: The sensitivity of the metal detector is crucial for detecting small metal contaminants that could be missed by less sensitive systems.

Speed: The speed of the metal detector should match the production speed of your line to prevent any slowdowns or bottlenecks.

Size: The size of the metal detector should match the size of your garments to ensure accurate detection.

Ease of use: The metal detector should be user-friendly and easy for operators to use and maintain.

Ensuring Quality Control with Metal Detection in Garment Production

Implementing metal detection systems in your garment production process is an effective way to ensure quality control. By detecting and removing metal contaminants, you can prevent faulty products from reaching customers, reducing the risk of product recalls and damage to your brand reputation.

Benefits of Implementing Metal Detection in Garment Production

Improved safety: Metal detection systems ensure that your garments are free of any metal objects that could cause harm to customers.

Enhanced quality control: By detecting and removing metal contaminants, you can ensure that your garments meet your quality standards and prevent faulty products from reaching customers.

Compliance: Implementing metal detection systems can help ensure compliance with industry regulations regarding metal contamination in products.

Cost savings: By preventing faulty products from reaching customers and reducing the risk of product recalls, metal detection systems can help save money in the long run.

Top Metal Detection Solutions for Garment Manufacturing

Conveyorized metal detectors: These metal detectors are designed to be integrated into conveyor systems, providing continuous detection of metal contaminants in garments as they move along the production line.

Handheld metal detectors: These portable metal detectors are ideal for spot-checking garments for metal contamination, either in production or post-production.

Tabletop metal detectors: These compact metal detectors are designed to be used on tabletops and are ideal for small-scale garment production.

X-ray inspection systems: X-ray inspection systems can detect not only metal contaminants but also other foreign objects that may be present