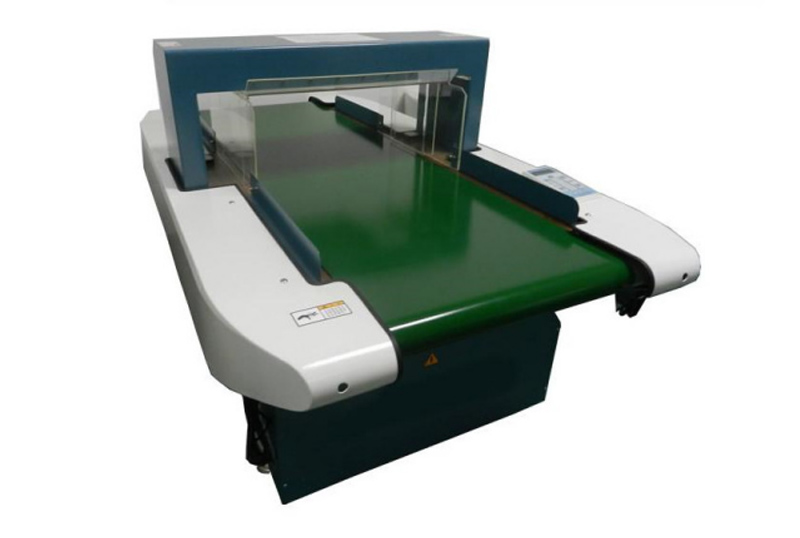

VMGT1 Table Needle Detector

Broken needle detector for sewing machines and other sewing accessories

The broken needle detector can detect the presence of broken needles in your sewing machine or other fabric-based accessory, allowing you to replace the faulty parts before they cause further damage. The broken needle detector is a highly effective tool for anyone who works with fabric-based materials, from professionals who make quilts to hobbyists who make patchwork quilts.

The broken needle detector uses an advanced detection system that can distinguish between broken needles and intact needles. It also has a built-in timer that can be set to alert you when it detects a broken needle—so you know when to get out your sewing machine, if your machine already has one of these devices installed!

The apparel industry is challenged every day by the need to produce a wide range of products in small quantities to satisfy consumers' tastes and competition from imported goods.

Many sewing factories want to innovate to increase their productivity and provide products within a short time frame. Quality improvement is just as important as productivity. The philosophy of the manufacturer is reflected in the quality of the products. To prevent products from being shipped with sewing machine needles or hand-sewing needles inside, it is important to inspect the product carefully. The most important equipment for quality control of sewing products is a needle detector.

In sewing factories, the production line includes processes such as cutting raw materials, sewing, finishing, inspection, and packing. The product is packed in cartons before being shipped. A conveyor-type needle detector is used in normal production lines to detect needles after the final process.

products. Other arrangements allow for the inspection and bagging of products through the needle detector.

Other types of needle detectors are available to accommodate different types of apparel and products that have been contracted to sew contractors.

Supporting the manufacturer is only possible if you can provide quality. The needle detector will give you peace of mind.

We have carved a niche in the market by providing a wide range of Needle Detectors. Our skilled professionals have designed the needle detector using top-quality raw materials and advanced technology. This needle detector has been rigorously tested for quality on various parameters. This product is highly sought after due to its high-quality attributes such as precise dimensions, user-friendly design, lighter weight, longer service life, and better overall performance.

ABS-plastic shell

Anti-static Cover

Integral control panel with touch-button interface

SMD technology

This product is suitable for AC power supply (full range).

SPECIFICAIONS

Method of detection: Magnetic induction. Digital process

Detection sensitivity ferrous 0.8mm higher (Standard test).

Detection adjustment: 1-10 level adjustment

Size of the Detection Zone: 350mm (L) x250mm (W)

Alarm method: Buzzer, Lamp

Power source: AC220 Vol 50-60HZ

Machine Dimension: 400mm(L)*255mm(W)*55mm(H)

Weight: Appr.11Kg

Industries That Utilize the biking Needle Detector

Theviking needle detector finds extensive use across various sectors where detecting metal contaminants is crucial. Here are some key industries that benefit from this technology:

Textile and Apparel

Clothing Manufacturing: Ensures garments are free from metal contaminants like needles and pins.

Shoe Production: Detects any unwanted metallic elements in footwear products.

Bedding and Home Textiles: Provides a safety check for items such as bedclothes and linens.

Toy and Consumer Goods

Toy Manufacturing: Detects metal fragments in rubber and plastic toys, ensuring child safety.

Fasteners and Accessories

Button and Zipper Production: Checks for metal impurities in fasteners and sewing accessories.

Food and Beverage

Food Processing: Screens products to ensure they are free from metal foreign bodies, safeguarding consumer health.

Meat and Seafood: Inspects meat, poultry, and fish processing lines for metallic contaminants.

Pharmaceuticals and Chemicals

Medicine Manufacturing: Protects the integrity of pharmaceutical products by detecting metal particles.

Chemical Processing: Identifies metal contaminants in chemical products to maintain quality control.

Each of these sectors relies on the viking needle detector to maintain product safety and quality, ensuring their offerings meet the highest standards.

Technical Parameters of the viking detector Needle Detector

Theviking detector needle detector offers robust specifications to ensure precise and reliable detection. Below is a detailed breakdown of its technical parameters:

Detection Capabilities

Detection Method: Utilizes electromagnetic induction for accurate needle detection.

Sensitivity: Can detect ferrous metal objects with varying sensitivities:

FeØ0.7mm

FeØ0.8mm

FeØ1.0mm

FeØ1.2mm

Dimensions and Weight

Detection Height Options: Available in 100mm, 120mm, 150mm, and 200mm heights.

Width: Standard width is 600mm, but customization options are available.

Device Dimensions: Measures 1650mm in length, 1050mm in width, and 900mm in height.

Weight: Approximately 180kg.

Performance and Power

Detection Adjustment: Sensitivity levels can be adjusted from 0 to 10, depending on the specific needs.

Alert Mechanisms: The device features multiple alert methods including audible alerts, automatic shutdown, and a reverse then restart function.

Power Requirements: Operates at AC220V, with a frequency range of 50-60Hz.

Power Consumption: Utilizes 100W of power.

These parameters make theXR-630Kneedle detector an efficient and versatile choice for tasks requiring high precision metal detection.