X ray needle inspection machine for garment,toys,shoes

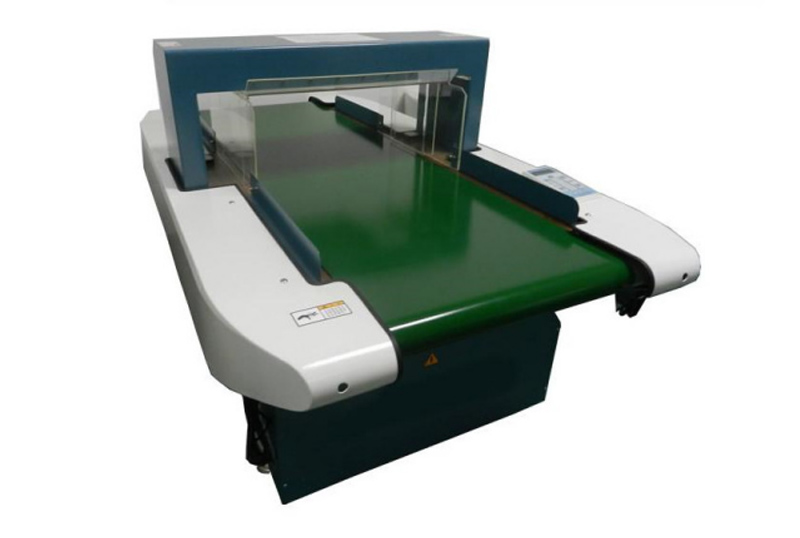

Overview of Industrial X-Ray Needle Inspection System

The Industrial X-ray needle Inspection System is a cutting-edge solution for garment manufacturers who need to ensure their products are free of metal contamination. This system is specifically designed to detect and locate needles and other metal objects in fabrics and garments, providing reliable and accurate results every time.

How It Works

The Industrial X-ray needle Inspection System works by using X-rays to scan fabrics and garments for metal objects. As the materials pass through the system, they are exposed to a low-dose X-ray beam. Any metal objects, such as needles or pins, will show up on the X-ray image, allowing the operator to quickly identify and remove them from the production line.

The system features advanced software algorithms that analyze the X-ray images in real-time, providing high-precision detection and low false-positive rates. The operator can view the X-ray images on a monitor and zoom in for a closer inspection of any potential metal objects.

Key Features

High-precision detection: The system is designed to provide highly accurate results, with low false-positive rates, ensuring that only genuine metal contaminants are identified.

Real-time image analysis: The system features advanced software that analyzes the X-ray images in real-time, providing immediate feedback to the operator.

Easy to use: The system is user-friendly and easy to operate, with a simple interface and intuitive controls.

Low maintenance: The system requires minimal maintenance, with long-lasting components and a durable design that can withstand the rigors of industrial use.

Customizable settings: The system can be customized to meet the specific needs of each production line, with adjustable sensitivity settings and other customizable features.

Benefits

Improved quality control: The Industrial X-Ray Needle Inspection System helps manufacturers ensure that their products are free of metal contaminants, improving overall quality control and reducing the risk of costly product recalls.

Increased efficiency: By quickly detecting and removing metal contaminants from the production line, the system helps manufacturers avoid downtime and increase overall efficiency.

Reduced labor costs: The system eliminates the need for manual inspections, reducing labor costs and improving productivity.

Compliance with industry regulations: The Industrial X-Ray Needle Inspection System helps manufacturers comply with industry regulations and standards, ensuring that their products are safe and free of metal contaminants.

Applications

The Industrial X-Ray Needle Inspection System is ideal for a wide range of clothing manufacturing applications, including:

Apparel production: The system is perfect for detecting metal contaminants in a variety of garments, including shirts, pants, dresses, and more.

Textile manufacturing: The system can be used to scan a range of textile materials, including cotton, polyester, and silk.

Uniform production: The system is well-suited for uniform manufacturers, helping to ensure that their products are free of metal contaminants.

Specialty clothing: The system can be used to inspect a variety of specialty clothing items, including sportswear, medical garments, and protective gear.

Conclusion

The Industrial X-Ray Needle Inspection System is a powerful tool for clothing manufacturers who need to ensure the quality and safety of their products. With its advanced X-ray scanning technology, high-precision detection, and customizable settings, this system provides reliable and accurate results every time. By investing in this system, manufacturers can improve their quality control processes, increase efficiency, and reduce labor costs, all while complying with industry regulations and standards.

X ray needle detector

Introducing the X-Ray needle detection Inspection Machine for garments, toys, and shoes!

This must-have tool is perfect for inspecting all types of clothing, including those with delicate fabrics and delicate materials. With its high-resolution imaging capabilities, this machine is sure to improve your quality control process and ensure that your products are of the highest standard.

Basic Info.

Model NO.:VZ4023

Type:Industry Alarm

Usage:Cordyceps

Tunnel Size:420*230mm

Detection Accuracy:Dia 1.2mm Metal Ball Is Visible

X-ray Generator:140KV generator

Sensor:Mufti-Mode CMOS Sensor From Japan, L Type

Monitor:19 " Medical Grade LCD Monitor

Voltage:180-240 V

Image Resolution:1024*768

Dimension:1660mm(L)* 730mm(W) * 1200mm (H)

Weight:310kgs

Power:600 W

Export Markets:Global

Additional Info.

Trademark:V finder Sense

Packing:Wooden Case

Standard:CE

Origin:Guangdong, China

Production Capacity:200PCS/Month

Product Description

Tunnel Specs:

The tunnel size can be customized according to the size of the object;

The width is from 400 to 650mm, the height is from 200 to 500mm.

General size is 420mm(Width) * 230mm(Height);

Quickly inspection

Conveyor speed: 10m/min,inspecting qty about 800 items/hour;

Detection accuracy: Dia 1.2mm metal ball is visible

High performance with good price:high performance same as of the imported equipment, but good price and service.

Printing Systems: photo printing,(barcode printing is an optional)

Functions & Parameters

X-ray generator: American original X-ray generator, both of current and voltage are adjustable

Sensor: Japanese original multi-mode CMOS sensor, L type,both sides operating;

Processor: DSP high-speed technology and system

Definition: excellent definition; 19"screen special for medical use; Obviously and visibly.

Processing software: advanced pattern recognition technology including neural networks and genetic algorithms.

Dimension: 1660mm (Length)* 730mm(Width) * 1200mm (Height)

Working height: 700-800mm to the ground,matches human mechanics;

Monitor:19" medical grade LCD monitor

Image Resolution: high resolution 1024*768 display,excellent imaging

Power and weight: 600 w; Voltage:180-240; Weight:310kgs

Rate of leakage: our standard is < 1usv/h, more safety than the international standrard as <5usv/h

Image Display: 1D imaging

Image Format: to generate JPG or PMP file, can output and store by USB fastly