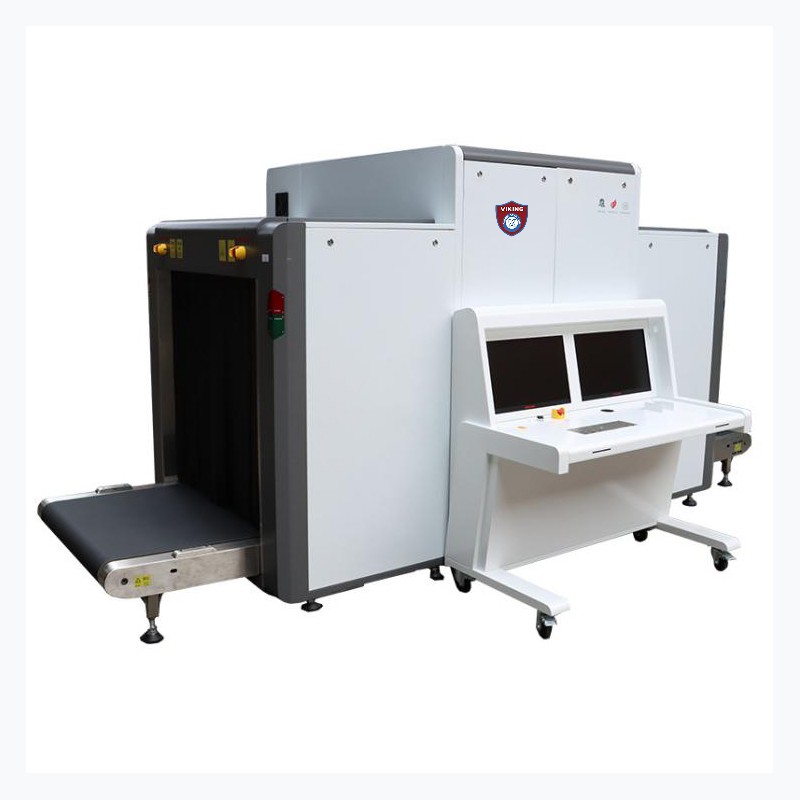

Dual View X-ray security inspection equipment machine VMS-10080D

The VMS-10080D (Dual View) stands as a beacon of advancement in the realm of medium-sized tunnel X-ray inspection systems, having received its certification from the Ministry of Public Security. This machine sets a global benchmark with its impressive capability to penetrate steel plates up to 46mm thick, alongside its exceptional line resolution of 0.0787mm for detecting a single solid copper wire of size 40AWG. It embodies efficiency and convenience with its one-touch power on/off feature and is recognized for its energy-saving attributes, making it an exemplary model for airport security and beyond.

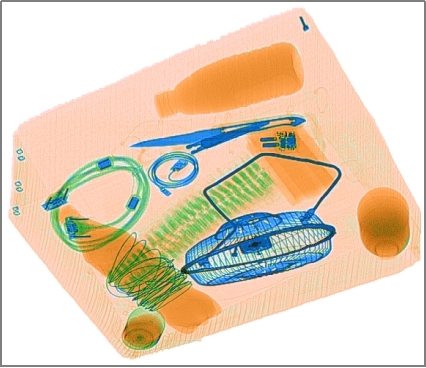

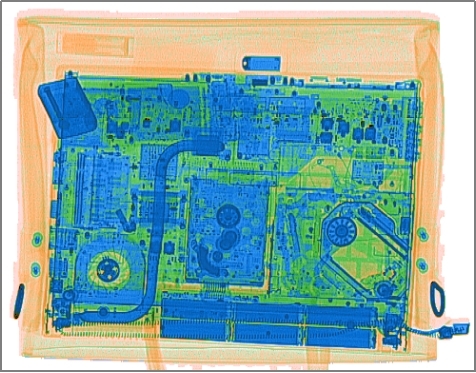

With its sophisticated material recognition technology, the VMS-10080D elevates the standards of safety inspection. This innovative system can accurately differentiate between organic, inorganic, and mixed materials by analyzing the effective atomic number of the object under inspection. This capability is enhanced by a color-coding scheme that aids operators in the swift identification and assessment of images, thereby streamlining the security process.

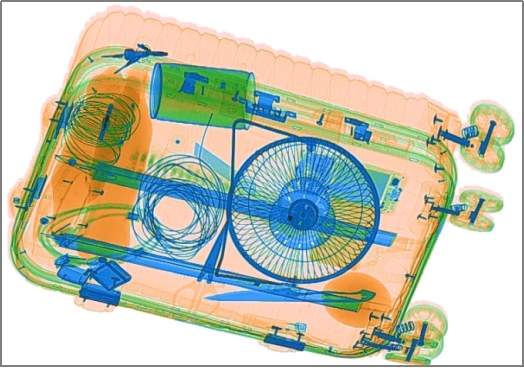

The cornerstone of the VMS-10080D's exceptional performance lies in its dual-view X-ray source inspection systems. These systems operate independently to collect comprehensive image data from both horizontal and vertical perspectives. This dual-view approach ensures that objects, regardless of their orientation, are scanned thoroughly, allowing the machine to construct a three-dimensional outline. This feature is invaluable in distinguishing the shape of various objects and effectively addressing the challenges of missed or false inspections that may occur due to obstructions.

Primarily, the VMS-10080D is deployed in high-security areas such as airports, where the detection of hidden prohibited items and hazardous materials is of utmost importance. This system excels in identifying a wide array of contraband, including but not limited to controlled knives, firearms, fireworks, and substances like alcohol, ethanol, gasoline, and sulfuric acid. Its adeptness in scanning medium and small-sized goods, packages, mail, and luggage ensures a comprehensive security cover, safeguarding against the entry of flammable and explosive materials that pose a threat to public safety.

In the context of airport security, the VMS-10080D (Dual View) X-ray machine represents a critical investment in safeguarding passengers and infrastructure. Its advanced detection capabilities, coupled with efficient operation, make it an indispensable tool in the arsenal of security measures. By facilitating the swift and accurate screening of baggage and cargo, it plays a pivotal role in maintaining the flow of safe travel, ensuring that potential threats are identified and mitigated with precision.

The deployment of such advanced X-ray inspection technology underscores a commitment to enhancing security protocols, adapting to evolving threats, and ensuring the safety of the traveling public. As airports continue to serve as gateways connecting various parts of the globe, the integration of systems like the VMS-10080D is essential in fostering a secure, efficient, and reliable air travel environment.

Dual View X-ray security scanning inspection equipment machine

Performance Features

· Clear image with a line resolution of 0.0787mm (40AWG) and a penetration power of 46mm steel plate.

· Equipped with high-end quality brands such as the British imported Sens-Tech acquisition system, Japanese Hamamatsu original detectors, and dual digital X-ray sources, ensuring stable quality and performance, representing the highest configuration in China.

· Features a 17-inch 1280*1024 high-resolution LCD display for clearer images.

· Extremely low radiation leakage dose rate, with the radiation dose rate around the equipment close to the natural background level, meeting international and domestic health and safety standards.

· Color/monochrome image switching, organic and inorganic material rejection, for easy differentiation of object types.

· Multiple image processing functions such as super enhancement, local enhancement, high penetration, low penetration, brightness increase, darkness decrease, gray sweep, magnification, and reduction, further increasing image clarity, and the ability to restore the initial image display with one click.

· Provides an automatic sensing function for energy-saving and convenience in operation.

· Offers a dangerous goods image insertion function (TIP function) for training and assessment of operators' image recognition abilities.

· Designed according to ergonomic principles, with a dedicated keyboard, image display, and human-computer interaction interface, effectively improving the simplicity of equipment use.

· Supports image saving function, which can be saved to USB storage devices and supports ".bmp", ".jpg", ".gif", ".png" image formats.

· Adopts a modular design, with each module handling different tasks, facilitating fault detection and maintenance.

· Unique anti-crushing hand design under the conveyor belt at the channel entrance and exit, on both sides of the channel, and on the loading rack, ensuring safety and reliability.

· Four corner indicator lights display the working status of the device from all angles, with a simple and beautiful appearance.

· Surface diamond pattern printing, more resistant to cutting and scratching during use; 3mm thickness is more resistant to stretching and deformation; surface static treatment, less likely to be contaminated during use.

· Made of national standard 304 stainless steel, 2-3mm national cold-rolled plate, and square tube steel, integrating advanced technology, with a stable and sturdy structure, rust-proof, corrosion-resistant, and cable damage prevention.

Technical Specifications

Detection Effect Images