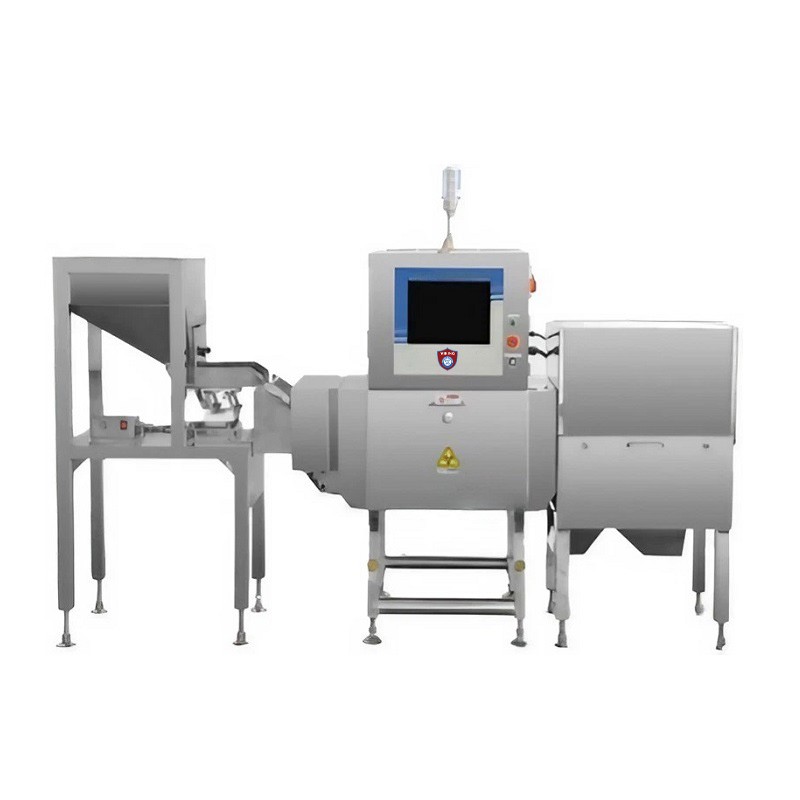

TXR-4080LP

X-ray Inspection System takes advantages of the penetrating power of X-ray to detect contamination. It can achieve a full range of contaminants inspection including metallic, non-metallic contaminants (glass, ceramic, stone, bone, hard rubber, hard plastic, etc). It can inspect metallic, non-metallic packaging and canned products, and the inspection

effect will not be affected by temperature, humidity, salt content, etc.

Product Features

Simple to Disassemble, Easy to Clean, and Reliable Security

●Good environment adaptability

●Equipped with industrial air conditioner

●Completely sealed structure to avoid dust

●Environmental humidity can reach 90%

●Environmental temperature can reach -10 to 40°C

Excellent Product Applicability

●up to eight grade image processing technology to achieve the best product adaptability and stability

Shielding Function

●cans shielding

●Desiccant shielding

●Boundary shielding

●sausage aluminum buckle shielding

High Configuration of Hardware

●Spare parts are well-known imported brands to ensure the performance and service life of the machine

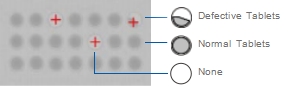

Defects Inspection Function

●The system will detect and inform tablet crack, tablet lacking and tablet with contamination

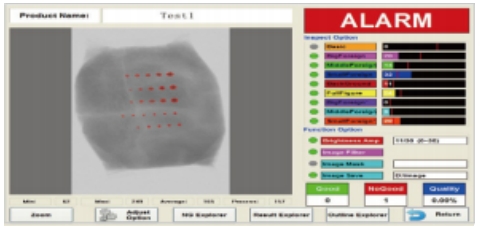

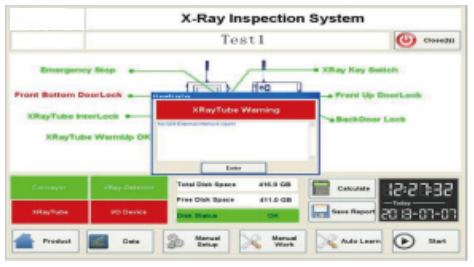

Excellent Operability

●15-inch touch screen display, easy to operate ,

●Auto-learning function. Equipment will automatically remember qualified product parameters

●Automatically save the product images , which is convenient for user's analysis and tracking

Comprehensive and Reliable Security

●X-ray leakage meets FDA and CE Standards

●perfect safe operation. monitoring to prevent the leakage from mis-operation.

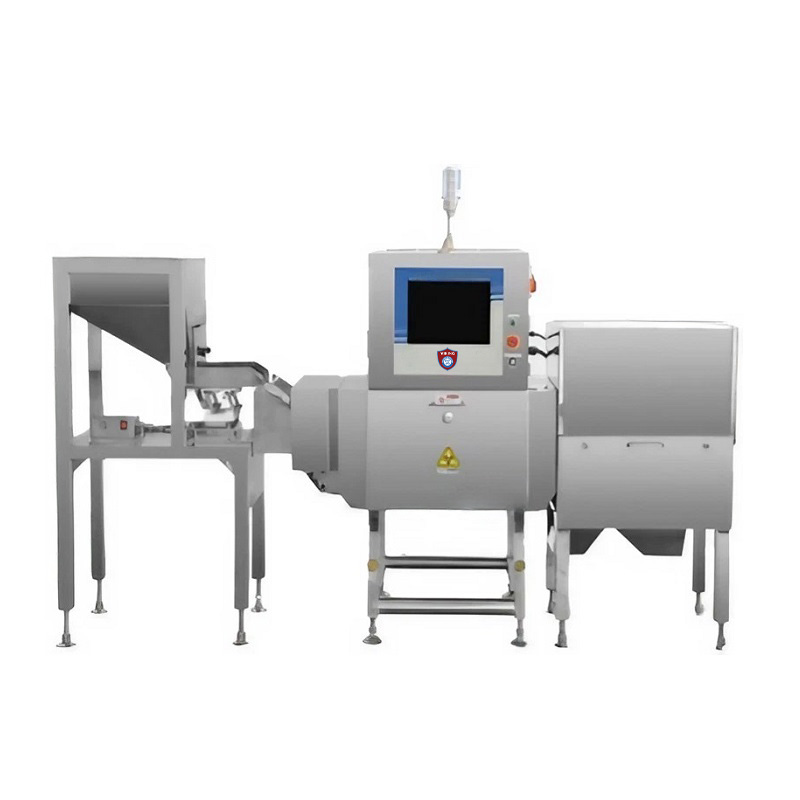

X-ray lnspection System for Bulk Products

It is widely used to inspect product like nuts grains, corns, raisins, sunflower seeds, beans, frozen fruits etc. in pre-packaging detection.

Product Specifications

Model | TXR-4080LP | TXR-4080P |

X-ray Tube | MAX. 80KV. 21OW | |

Inspection Width | 400 mm | |

Inspection Height | 50mm (MAX) | 160mm (MAX) |

Best Inspection Sensitivity | stainless steel ball Φ0.3mm stainless steel wire Φ0.2*2 mm Glass/ceramic ball Φ1.0mm | |

Conveyor Speed | 60m/min | |

O/S | windows 7 | |

Protection Method | SUS shield | |

X-ray Leakage | < 1usv/h (CE Standard) | |

IP Rate | IP66 (under belt) | |

Wording Environment | Temperature: 0 to 40°c | |

Humidity: 30 to 90% no dew | ||

Coding Method | Industrial air conditioning | |

Rejecter Mode | 32 tunnel air jet rejecter or 4/2/1 channels fap rejecter | |

Air Pressure | 0.8Mpa | |

Power Supply | 1.5kw | |

Main Material | SUS304 | |

Surface Treatment | Mirror polished/sand blasted | |

Note:

The technical parameter above namely is the result of sensitivity by inspecting only the test sample on the belt. The actual sensitivity would be affected according to the products being inspected.

Product Configuration