bottle checkweigher

precise bottle checkweighers

Our precise bottle checkweighers are high-performance machines designed to ensure accuracy and consistency in weight verification for packaged products in bottles.

Equipped with advanced technology and reliable components, our checkweighers provide precise weight measurement for every single bottle, enabling you to identify and reject underweight or overweight products.

With their fast and efficient operation, our checkweighers can seamlessly integrate into your production line, allowing for continuous and uninterrupted manufacturing.

They are also easy to operate and maintain, providing a hassle-free solution for your packaging needs.

Our bottle checkweighers are built to meet industry standards and regulations, ensuring compliance with strict weight requirements.

By using our checkweighers, you can prevent product giveaway, reduce waste, and increase profitability.

Whether you are in the food and beverage, pharmaceutical, or chemical industry, our bottle checkweighers are versatile and can be customized to

meet your specific needs. Trust us to provide you with a reliable and effective solution for ensuring consistency and compliance in your packaging process.

Product Description:

This product is suitable for online automatic weighing, underweight detection, missing accessories detection, and leak detection of small packaging boxes, small bags, and extremely small single products. It is widely used in electronics, pharmaceuticals, food and beverage, health products, daily chemicals, light industry, agriculture and other industries.

Product Features Of bottle checkweigher

Strong universality: The standardized structure and human-machine interface of the whole machine can complete the weighing of various materials.

Adjustable speed: Variable frequency control motor is used, and the speed can be adjusted according to needs.

High speed and high precision: High-precision digital sensors are used, with fast sampling speed and high accuracy.

Zero tracking: Manual or automatic zero clearing, as well as dynamic zero tracking.

Reporting function: Built-in reporting statistics, reports can be generated in Excel format, can generate a variety of real-time data reports, external USB interface, real-time export of data, and grasp the production situation at any time. Provides factory parameter setting recovery function, and can store multiple formulas for easy replacement of product specifications.

Interface function: Reserved standard interface, data is easy to manage, can be connected with PC and other intelligent devices for communication.

Self-learning: After creating product formula information, there is no need to set parameters. The self-learning function can automatically set suitable parameters for the equipment and store them for easy use when switching products. (The number of parameter storage items is 2000 and can be increased).

Technical of bottle checkweigher

Model number | CVW2512 |

Power supplier | AC220V±10% 50HZ(60HZ) |

Power consume | 0.1KW |

Weight range | ≤200g |

Accurancy | ±0.1g~±0.3(depends on product size and speed ) |

Mini resolution | 0.01g |

Conveyor speed | 20~70m/min |

Check speed | 60~160 pcs/min |

Suitable for product size | ≤100mm(L)*100mm(W) |

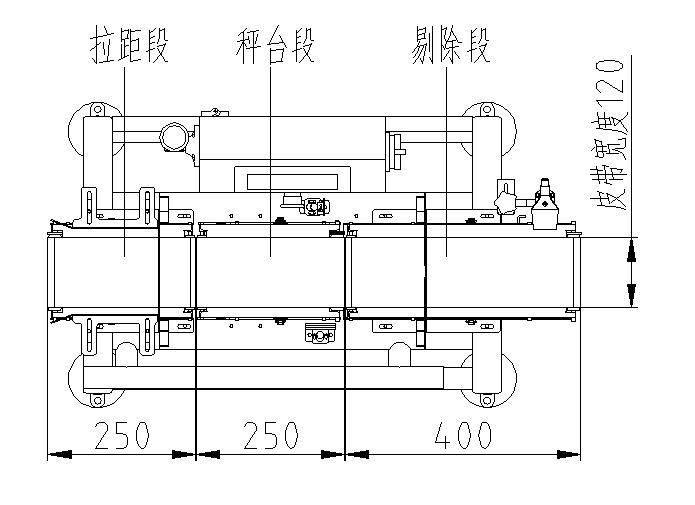

Weighting zone size | 250mm(L)*120mm(W) |

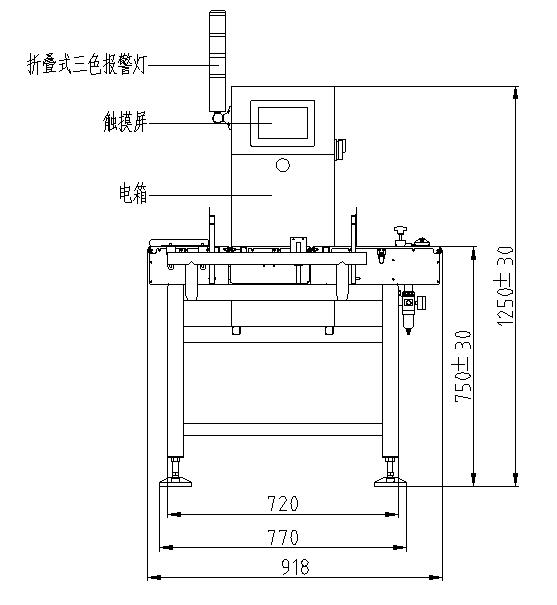

Product size | 900mm(L)*500mm(W)*1250mm(H) |

Rejection | Air blast/push rod |

Control system | High speed A/D controller |

Product storage | 2000 |

Runing direction | Left to right or customized |

Penumatic request | 0.6-1Mpa |

Penumatic | Φ8mm |

Work environment | Temperature: 0℃~40℃,humidity:30%~95% |

Machine structure | SUS304 stainless steel |

Main parts of bottle checkweigher

Brand | Name | Size | (单机)Pcs |

View | Touch screen | 7 inches | 1 |

HBM | Load cell | 10KG | 1 |

Omron | Switch | S8JC-C100 24C | 1 |

MOSO | Control swtich | SLD2(3LD2-32A) | 1 |

Siemens | frequency transformer | V20 Transformer single phase 220V 0.12KW | 1 |

STS/Motor | Motor | Three phase 220V 25W | 3 |

CAD drawing of bottle checkweigher