checkweigher food industry

checkweigher for the food industry

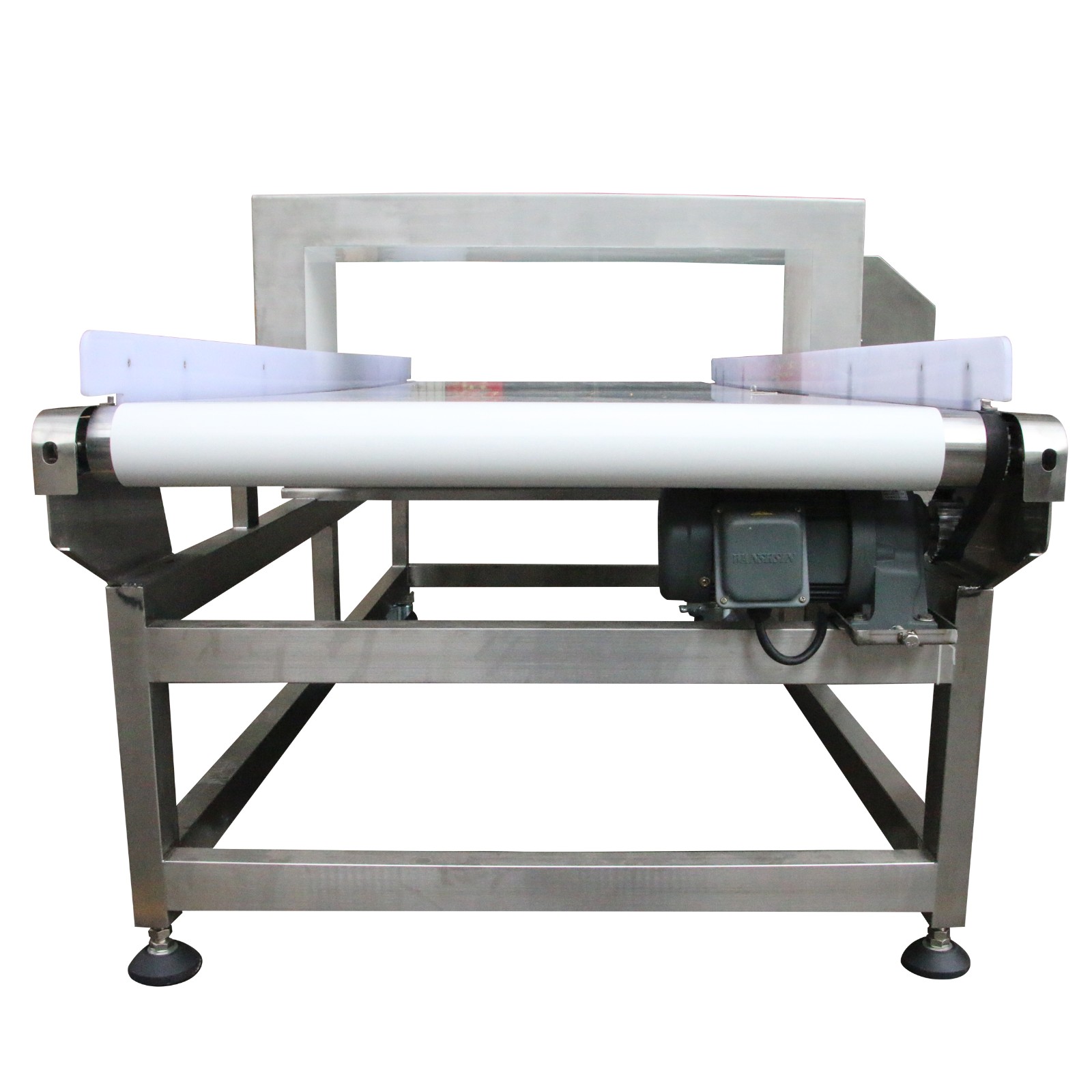

A checkweigher for the food industry is a highly accurate weighing system that is designed to ensure that packaged food products are within the predetermined weight range. This equipment typically consists of a conveyor belt, a load cell or weighing mechanism, and a reject mechanism that removes any products that fall outside of the specified weight range.

Checkweighers can be integrated into food processing lines to weigh individual products, such as packaged meats, baked goods, or snack foods, as they move down the line. The system can then automatically reject any products that do not meet the required weight standards, ensuring that only high-quality, consistent products make it to the end of the line.

In addition to improving product quality and consistency, checkweighers can also help food manufacturers comply with regulatory requirements and reduce waste. By accurately weighing products and rejecting any items that fall outside of the specified weight range, manufacturers can minimize product giveaway and maximize profits.

Overall, checkweighers are an essential tool in the food industry for ensuring product quality, regulatory compliance, and profitability.

Performance characteristics

▲ Good detection stability, fast speed, high precision, special structure design, can effectively avoid external interference;

▲ It can preset 100 recipes, import production data into U disk with one click, and trace 100,000 weight data;

▲ Comply with GMP standard requirements, easy to disassemble and easy to clean;

▲ Intuitive operation and multi-language screen can be finalized with one key, the information is clear at a glance, and the operation efficiency is maximized;

▲ Optional remote monitoring system, Ethernet connection can effectively monitor the equipment status;

▲ The specially designed overload protection structure can effectively protect the sensor from damage under the heavy pressure of hundreds of times the range of objects, so that the weighing accuracy is intact.

Model and parameters

model | KH500C3/MR | KH2KC3/MR | KH5KC3/MR | KH7KC3/MR |

Max weighing | 500g | 2000g | 5000g | 7000g |

Accuracy | ±0.2g/±0.1g | ±0.5g/±0.2g | ±1g/±0.5g | ±2g/±1 |

top speed | 300P/min | 240P/min | 180P/min | 120P/min |

Weighing platform length | 200-300mm | 250-350mm | 300-400mm | 300-450mm |

Belt width | 200mm | 200-250mm | 200-350mm | 200-400mm |

conveying direction | about | about | about | about |

table height | 500-1200mm | 500-1200mm | 500-1200mm | 500-1200mm |

Removal method | Air blow/flip | Air blow/flip | Push rod / flapper / flap | Push rod / flapper / flap |

Note: The voltage of the above models is 220VAC, 50/60HZ, and the current is less than or equal to 2.5A; other sizes and special requirements can be customized.