IXL-160 Automatic Checkweighing Machines

Checkweigher IXL Series

Unleashing Precision in Packaging - Introduction to our Checkweigher Solution**

In the dynamic realm of packaging, precision and efficiency are critical factors that can make or break a brand's reputation. Our Checkweigher for Packaging Lines emerges as a game-changer, offering a comprehensive solution to optimize efficiency and ensure unparalleled precision in the packaging process. Let's delve into the key features and advantages that make our Checkweigher an indispensable asset for businesses across various industries.

Precision at Its Core - Understanding the Checkweigher Technology**

At the heart of our Checkweigher lies cutting-edge technology designed to deliver precise weighing results in real-time. The system employs dynamic weighing technology that swiftly verifies the weight of each package as it moves through the production line. This ensures that every product leaving the packaging line meets the specified weight standards with exceptional accuracy.

Seamless Integration into Packaging Lines**

Our Checkweigher is engineered for seamless integration into packaging lines, allowing for continuous and automated weighing. The system effortlessly adapts to the fast-paced nature of packaging operations, contributing to a smooth and efficient workflow. Its automated functionality minimizes manual intervention, reducing the chances of errors and enhancing overall production efficiency.

High-Speed Weighing Solutions for Increased Throughput**

Speed is of the essence in modern packaging facilities, and our Checkweigher rises to the challenge with high-speed weighing solutions. The system operates at a pace that aligns with the demands of high-throughput production lines. This not only accelerates the packaging process but also ensures that products are swiftly weighed and verified without causing bottlenecks in the overall production workflow.

Ensuring Compliance and Quality Assurance**

In industries where regulatory compliance is paramount, our Checkweigher becomes a key player in meeting and exceeding these standards. The system is meticulously designed to operate flawlessly in diverse sectors, including food and pharmaceuticals, ensuring that products comply with weight regulations. This commitment to quality assurance strengthens brand reliability and customer trust.

Tailored Solutions for Various Industries**

Our Checkweigher is not a one-size-fits-all solution; rather, it is a versatile tool that caters to the unique needs of various industries. Whether in the food sector, where precise packaging is crucial, or in pharmaceuticals, where regulatory compliance is non-negotiable, our Checkweigher provides tailored solutions. Its adaptability makes it an asset for businesses looking to elevate their packaging operations across different product lines.

Immediate Corrective Action for Deviations**

One of the standout features of our Checkweigher is its ability to take immediate corrective action in the event of weight deviations. Any product falling outside the specified weight range triggers an instant response, allowing for quick adjustments and minimizing the chances of underweight or overweight products reaching the market. This real-time correction capability adds an extra layer of quality control to the packaging process.

Enhancing Brand Reputation through Consistent Quality**

Consistency is key to building and maintaining a strong brand reputation. Our Checkweigher plays a pivotal role in ensuring the consistent quality of packaged products. By upholding precise weight standards, businesses using our Checkweigher send a powerful message to consumers – a message of reliability, attention to detail, and a commitment to delivering products that meet and exceed expectations.

In conclusion, our Checkweigher for Packaging Lines is more than a piece of equipment; it's a strategic investment in the efficiency, precision, and reputation of your brand. From its advanced weighing technology to its seamless integration into diverse production lines, our Checkweigher sets new standards in the world of packaging. Elevate your packaging operations, meet regulatory requirements, and build consumer trust with our Checkweigher – the precision solution for modern packaging challenges.

Suitable for weight checking for packaged products , to ensure quality standards

●High speed , high sensitivity, high stability dynamic weight checking

●Easy to clean , simple to disassemble

Product Features

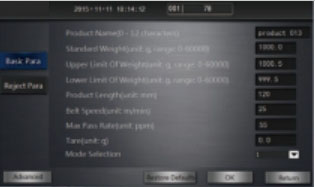

User-friendly Function

●Multi languages

●Data storage

●Large memory capacity

High Configuration

●Touch screen

●USB Port,Ethernet function

●Real time monitoring on PC

Brief User Parameter Setting

check weigher for small package

Product Specifications

Model | XL-160 | IXL-230S | IXL-230L | IXL -300 | IXL -400 | |

Detecting Range | 5 to 600g | 20 to 2000g | 20 to 2000g | 20 to 5000g | 0.2 to 10kg | |

Scale Interval | 0.05g | 0.1g | 0.1g | 0.2g | 1g | |

Accuracy (3o) | ±0.1g | ±0.2g | ±0.2g | ±0. 5g | ±1g | |

Max Speed | 250pcs/min | 200pcs/min | 155pcs/min | 140pcs/min | 105pcs/min | |

Belt Speed | 70m/min | 70m/min | 70mv/min | 70m/min | 70m/min | |

Weighed Product Size | Width | 150mm | 220mm | 220mm | 290mm | 390mm |

Length | 200mm | 250mm | 350mm | 400mm | 500mm | |

Weigher Platform Size | Width | 160mm | 230mm | 230mm | 300mm | 400mm |

Length | 280mm | 350mm | 450mm | 500mm | 650mm | |

Operation Screen | 7" touch screen | |||||

Product Storage Quantity | 1 00 kinds | |||||

Segments Number | 3 | |||||

Rejecter Mode | Rejecter optional | |||||

Power Supply | 220v (optional) | |||||

IP Rate | IP54/IP66 | |||||

Main Material | Mirror polished/sand blasted | |||||

Note:

The technical parameter above namely is the resut of accuracy by checkin ony the test sample on the bert. The accuray

would be afected according to the detecting speed and product weight.

2. The detecting speed above will be affected according to the product size to be checked.

3. Requirements for different sizes by customers can be fulfilled

Product Configuration