conveyor metal detector for food

conveyor belt metal detector for food

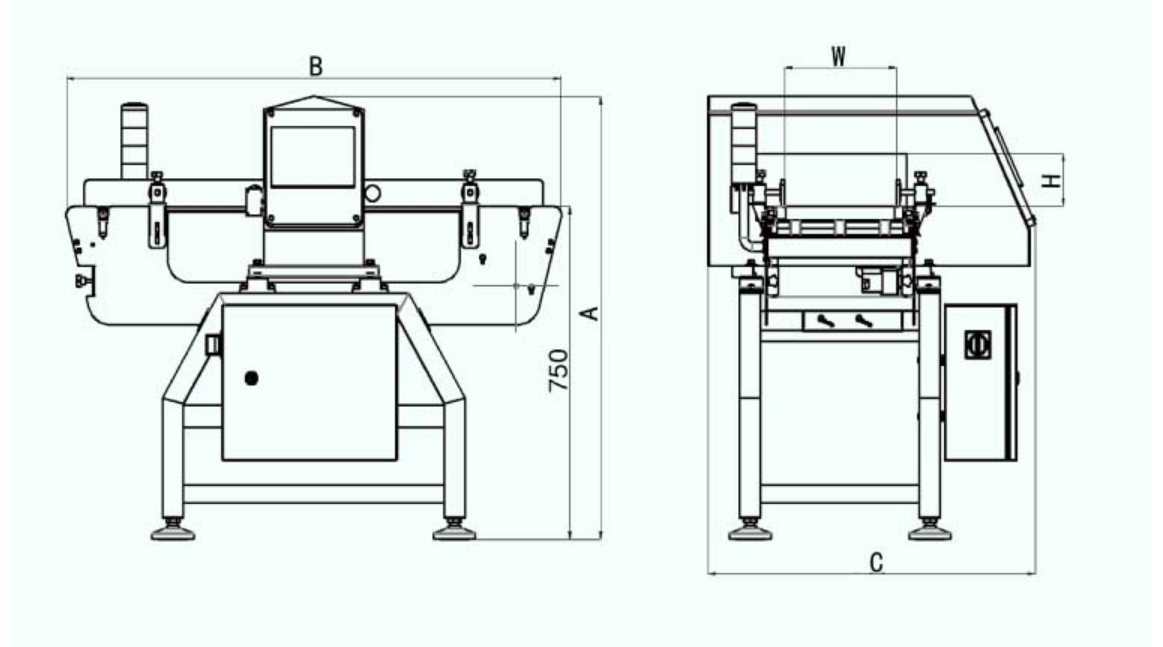

Our conveyor belt metal detector is a high-tech, automated device that detects metal, metal particles, free fall, stainless steel, metal contamination and

other types of food products. It is used in food processing plants and factories as well as industrial applications.

The high-frequency electromagnetic field of the conveyor belt metal detector can detect the presence of metals in various forms, including powders or sludge.

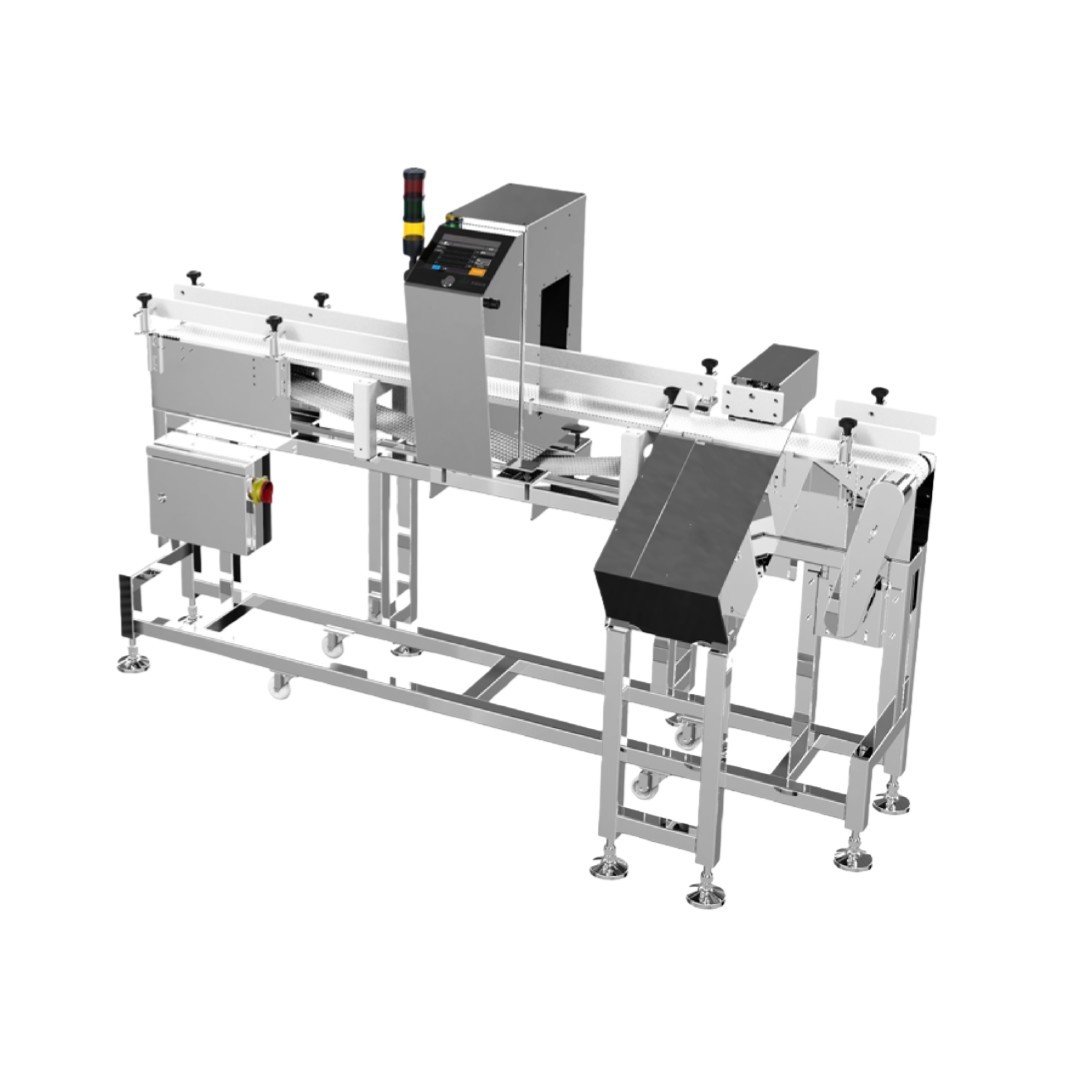

Production line conveyor belt metal detector

Our conveyor belt metal detector can be used for inspection of the entire production line from pre-processing to packaging. With a wide range of detection capabilities and an advanced detection system, our conveyor belt metal detector can inspect any type of product.

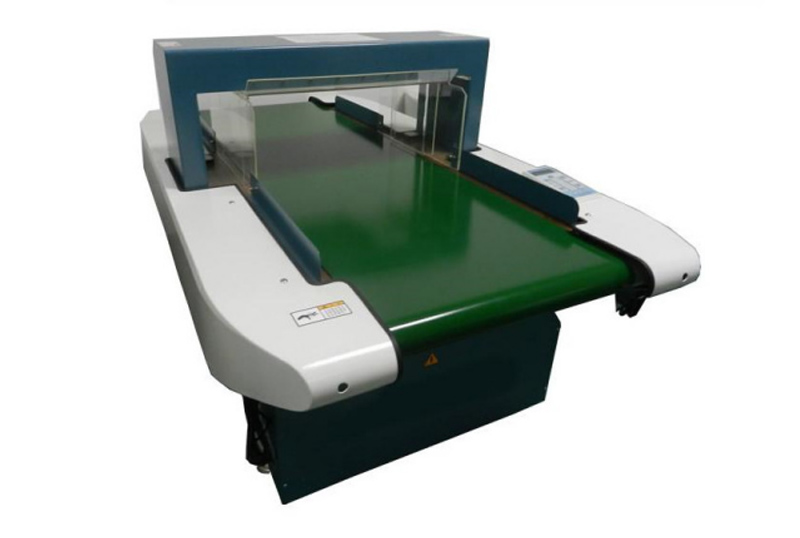

Food industry.conveyor metal detector

The food industry is a large and complex network of processes and products. The main purpose of the food industry is to ensure that the food products are

safe and fit for consumption, as well as to meet the requirements of consumers. The production process involves many stages, such as processing,

storage, packaging and transportation. In order to ensure that all stages of production are carried out in accordance with standards and regulations,

it is necessary to have an effective metal detector inspection system.

During the production process, it is possible that some components may be contaminated by metal particles or other substances from outside sources such as scrap metal or pipes.

It is therefore necessary to have a metal detector which can detect metal contamination during production processes such as:

Conveyor metal detector for production lines

Production lines that produce food products

Production lines that produce beverages

Food industry equipment

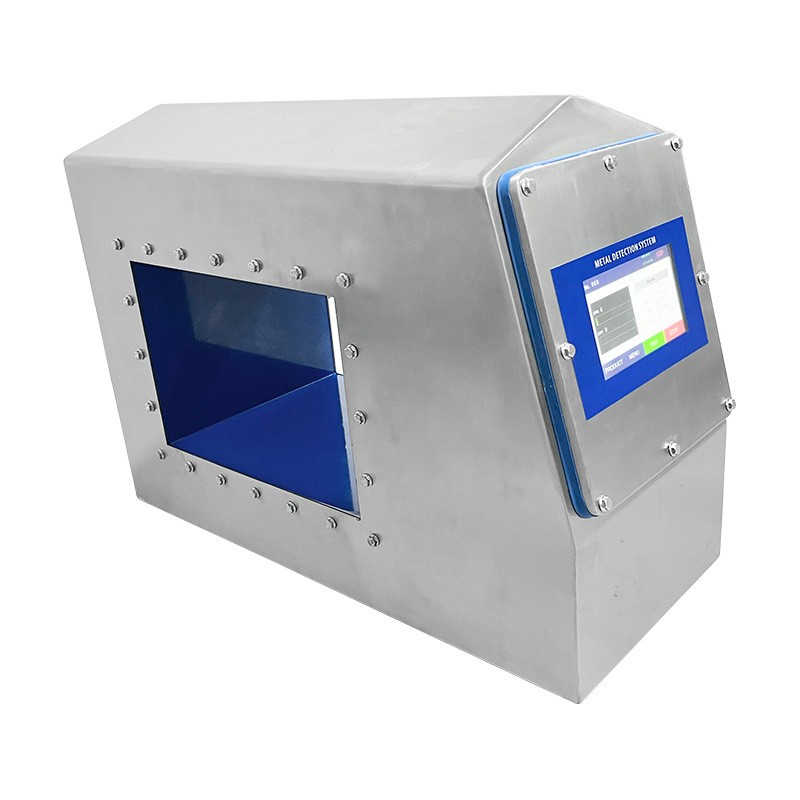

conveyor metal detector Features and Benefits:

1. Automatic phase adjustment technology can effectively inhibit the product effect; it can detect the products with high product effect, such as frozen food, meat, rice, pickled products, fish pulp, etc.

2. With intelligent setting, the device can automatically set the best sensitivity suitable for the product to be tested, and the operation is simple and convenient.

3.Memory function: the best sensitivity can be saved,the next test can be directly detected, and the detection parameters of more than 50 products can be stored.

4.LCD Touch screen display, Chinese and English menu screen, easy to realize man-machine dialogue operation.

5. Detects ferrous and non-ferrous metals, including stainless steel

6. Digital sensitivity control mode and a variety of advanced manual setting functions; various specifications can be selected to adapt to different material detection sensitivity requirements.

7. Made of stainless steel SUS304, high-grade protection motor for selection; the highest ip69 protection grade, suitable for extremely harsh working environment.

8. Simple and detachable rack is convenient for users to clean; the special design of conveyor belt can avoid belt deviation.

9. A variety of elimination methods are available: accurate elimination control ensures the reliability of foreian matters and the minimum waste of materials