Food grade conveyorized packaging metal detectors

Inroduce of metal detector for food packaging

The food packaging metal detector is an effective way to avoid metal contamination. By using this product, you can avoid the risk of metal entering your food, and causing health problems for you and your customers.

Conveyor. packaging Metal Detectors employ a sturdy rectangular head to scan products that are being carried through an aperture by a conveyor belt. This is used in food processing and packaging applications.

What are the benefits of using a metal detector for food packaging?

1.food packaging metal detector can help to ensure that the food you are buying is safe and of the correct standard.

2. It can help to avoid any complaints from customers who may be concerned about metal contamination.

3. It can help to protect your machine from costly repairs.

4. Ferrous metal contaminants are both magnetic and conductive and are easily detected.

why are metal detectors used in food packaging ?

Metal detectors are used in food packaging. Food lines use metal detectors to protect consumers.

Metal contaminations can still occur during packaging. Consumers may be seriously injured if metal particles

are introduced to the product in the manufacturing process. Producers may face serious consequences, including

costly recalls and compensation claims. Improper food products can cause even more damage and longer-lasting problems.

Food packaging with metal detectors provides effective protection against non-ferrous and ferrous metals (aluminium or stainless steel). ).

Metal detector in packaging solution

The complete packaing solution, including an integrated Vector Conveyor and detection system, is available. Freefalling loose products, such as grains and powders. For bulk products such as cereals, flour, and rice, gravity metal detectors can be used to integrate them into existing systems. The product being tested is gravity-fed through a pipeline system and passes through the detector's aperture. A gravity system typically includes an automatic reject system that removes contaminated product from the flow. This ensures that only the best quality products are packaged for distribution. Freefalling products before packaging. The VFF Detection system is designed to serve retail products such as frozen vegetables and chips that are packed in bags or pouches. The VDF2212 is small enough to fit in tight spaces and can also be used before final packaging. For optimal performance, the unit can be placed under a Multihead weighter or combined with a Vertical Form Fill Seal to ensure maximum efficiency. It is possible to mount the wired remote control panel in an easier-to-reach location, which makes it more convenient for operation. VLF is the best solution when packaging is too heavy or metallic for standard detectors. Product that is typically pumped through pipes. Unpackaged products are transported through pipes using pipeline systems. Because of the wet product application, pipeline metal detectors come with BSH Rugged Casing or Stainless Steel construction for IP69K protected protection. This ensures that products retain their quality and provides a safe working environment. Pipeline systems are typically inserted at the end of a process line. These products are usually pumped liquids or pastes. However, the same principles can also be applied to other applications, such as sausage meat, where the product has been dried and blown through pipes. Filled plastic and glass bottles For detection of filler vent pipes, the liquid detectors model VLP can be integrated into existing bottling lines. It is usually located on the outfeed of a filler machine or bottle processing machine. The system can be interconnected to line controls and inspection systems. To detect a vent tube in the product, the system can be connected to existing fill level and monitoring equipment.

Models of food packaging metal detectors

Model VMD Series gravity fed models :

Model VFF Series with modularization belt :

Model VDF2212 smart high accuate metal detector food grade:

Model VLF pipeline model with rejection for beverafe or sauce :

Food packaging metal detector Features:

1,We are FDA approved 304 stainless steel mesh fabric type

2,It has three different adjustable speed ranges

3.Lights and sounds are designed to activate when the device is in non-compliant conditions

4.The ferrous 0.8 mm, non-ferrous 1.5 mm structure is FDA compliant

We can customize it based on your package line dimensions.

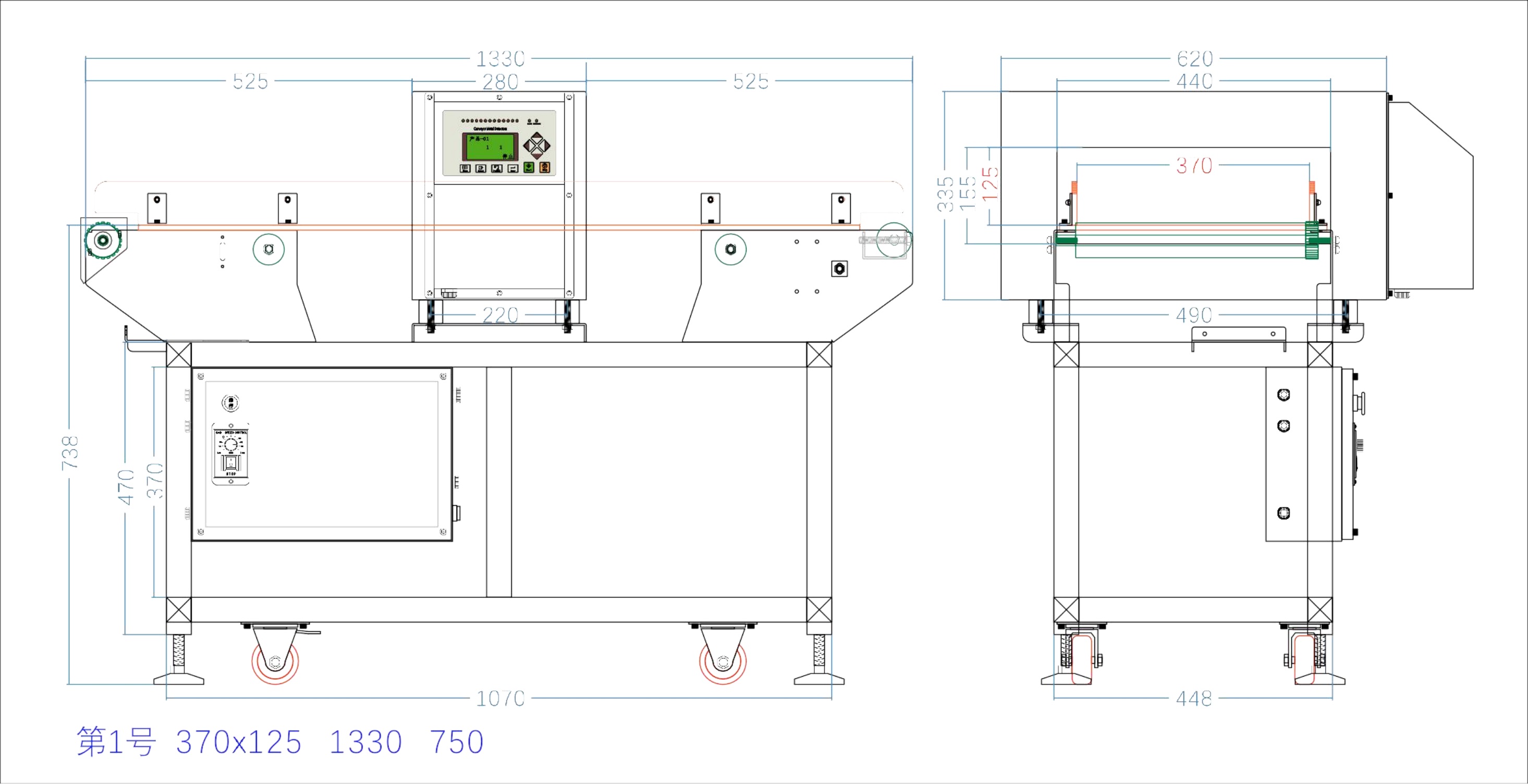

metal detector for packaging line Related drawing