metal detection in food processing

Quality Control Metal Detection Inspections for Food Processing

Ensure the highest standards in food safety with our advanced Quality Control Metal Detection Inspections. Designed specifically for food processing environments, these metal detectors provide a robust solution to detect and eliminate metal contaminants, ensuring the integrity of your products.

**Key Features:**

**1. Precise Metal Detection:**

Utilizing cutting-edge metal detection technology, our inspection systems offer precise and reliable detection of metallic contaminants in food products. Enhance your quality control measures with advanced inspection capabilities.

**2. Tailored for Food Processing:**

Engineered with the unique challenges of the food processing industry in mind, our metal detection inspections are equipped to handle the specific requirements of detecting metal contaminants in various food products.

**3. Compliance Assurance:**

Meet regulatory standards and industry compliance with confidence. Our quality control metal detection inspections contribute to ensuring that your products adhere to the highest safety and quality standards.

**4. Seamless Integration:**

Integrate our metal detection inspections seamlessly into your food processing line. Designed for efficiency, these systems work harmoniously with your production processes, minimizing disruptions while maximizing safety.

**5. Keyword Focus: Metal Detection in Food Processing**

Elevate Food Safety with Metal Detection Inspections**

Safeguard your brand reputation and consumer trust by implementing our Quality Control Metal Detection Inspections. Elevate food safety standards, meet compliance requirements, and deliver products free from metal contaminants.

Advanced Technology for Accurate Detection**

Our metal detection inspections utilize advanced technology to deliver accurate and reliable results. Detect and eliminate metal contaminants, ensuring that your food products meet the highest safety standards.

Industry-Tailored Solutions for Food Processing**

Tailored to the unique needs of the food processing industry, our metal detection inspections provide industry-specific solutions for detecting and preventing metal contamination in food products.

Seamless Integration for Efficient Production**

Integrate our quality control inspections seamlessly into your production line for efficient and uninterrupted processing. Prioritize food safety without compromising productivity.

Invest in the assurance of quality and safety for your food products with our Quality Control Metal Detection Inspections. Elevate your quality control processes and build trust with consumers by prioritizing metal detection in food processing.

Principle of metal detection

The principle of metal detection machine is based on electromagnetic energy. A coil is wrapped around the object to be detected and a permanent magnet is attached to it. The coil has an electrical circuit that produces an alternating magnetic field. The alternating magnetic field produced by the coil excites electrons in the object, causing it to emit radio waves. The radio waves are received by a receiver coil and converted into an electrical signal. The electrical signal is then processed by a computer which displays a corresponding symbol on an LED display screen or LED panel.

Metal detection machines are used to detect metallic objects in food. They can also be used for drug and bomb detection.

metal detection for food processing

Metal detection is a process of testing for the presence of metals in food and liquids. It's used as a pretreatment to help prevent the contamination of food or drinks by metal fragments or foreign bodies, which can cause illness or even death. Metal detectors are used in many industries, including food processing, petrochemical manufacturing, pharmaceuticals and medical imaging.

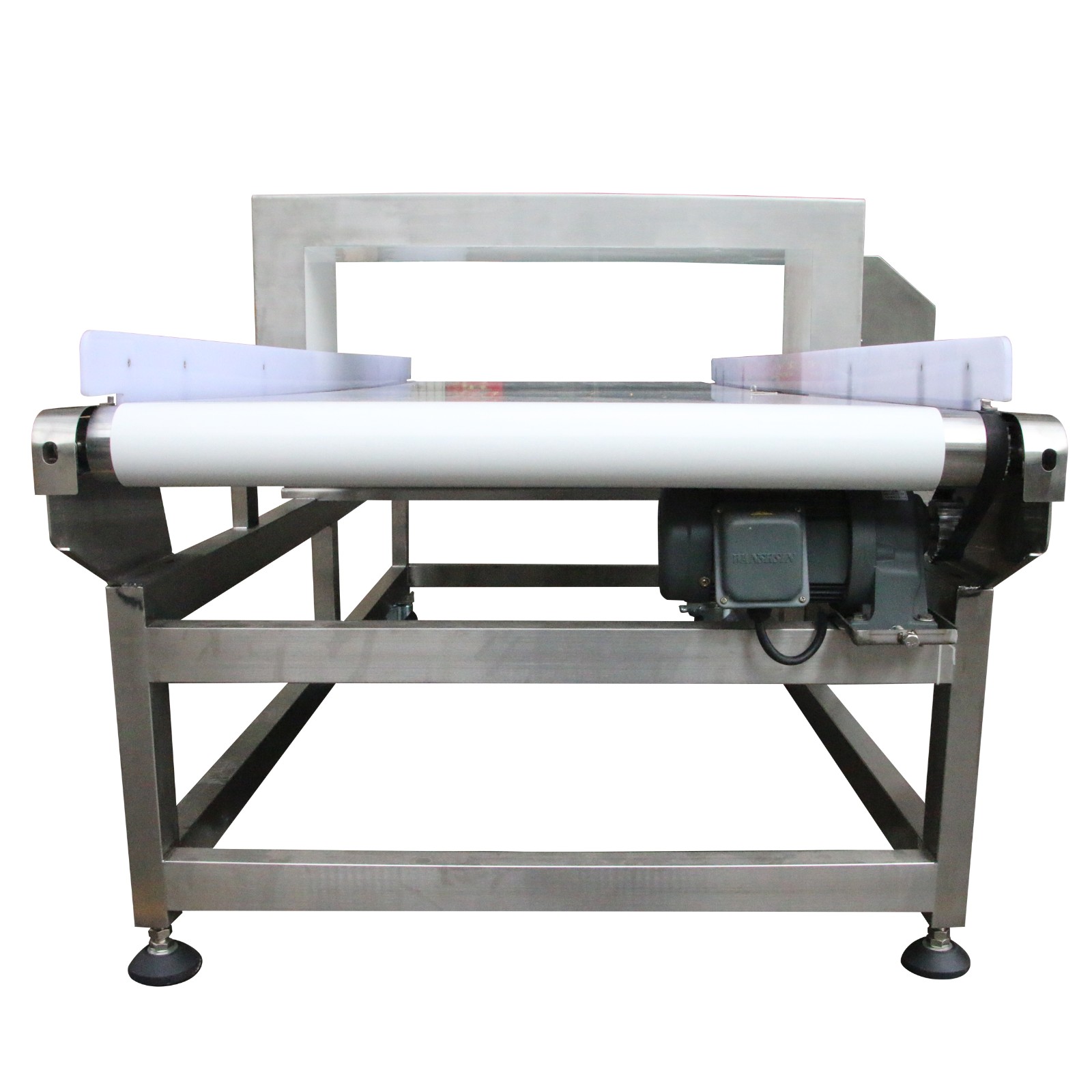

Metal detection equipment

Metal detection equipment is a critical component of the food processing industry. It helps to ensure that the products being processed are free from dangerous levels of metal contamination, which can lead to serious food safety issues.

The [Dongguan Viking] metal detection machines have been designed with specific features that make them ideal for use in food processing facilities. They are:

-Reliable: The [Dongguan Viking] metal detection systems are built to last so you don't have to replace them every year or two like some less reliable models do.

-Safe: Unlike other types of metal detectors that use X-rays or radio waves to detect metals in foods, these machines do not emit any radiation or cause any harm when used properly.

-Effective: These machines are highly effective at detecting all kinds of metals, including lead, tin, and nickel.