aluminum foil free electronic magnetic metal detection

# Elevating Food Safety with Aluminum Package Metal Detectors in the Food Processing Industry

In the intricate realm of food processing, ensuring the safety and integrity of packaged products is paramount. The utilization of advanced technologies, such as aluminum package metal detectors, emerges as a crucial element in safeguarding the quality of food products. This comprehensive exploration delves into the intricacies of aluminum package metal detectors in the food processing industry, elucidating their significance, operational mechanisms, technological specifications, and the multifaceted benefits they offer to manufacturers and consumers alike.

## I. Introduction

### A. Imperative for Enhanced Food Safety

The food processing industry operates within a regulatory framework that demands strict adherence to safety standards. Contaminants, including metal particles, pose a significant threat to both the quality of packaged products and consumer well-being. Aluminum package metal detectors serve as a proactive solution to mitigate these risks, providing a robust defense against unwanted metallic contaminants.

### B. Evolution of Metal Detection in Food Processing

Traditionally, manual inspection and rudimentary metal detectors were employed to identify metal contaminants in packaged foods. However, with the evolution of technology, aluminum package metal detectors have emerged as sophisticated and highly effective tools for ensuring the safety and quality of food products during the processing and packaging stages.

## II. Operational Mechanism of Aluminum Package Metal Detectors

### A. Integration into Processing Lines

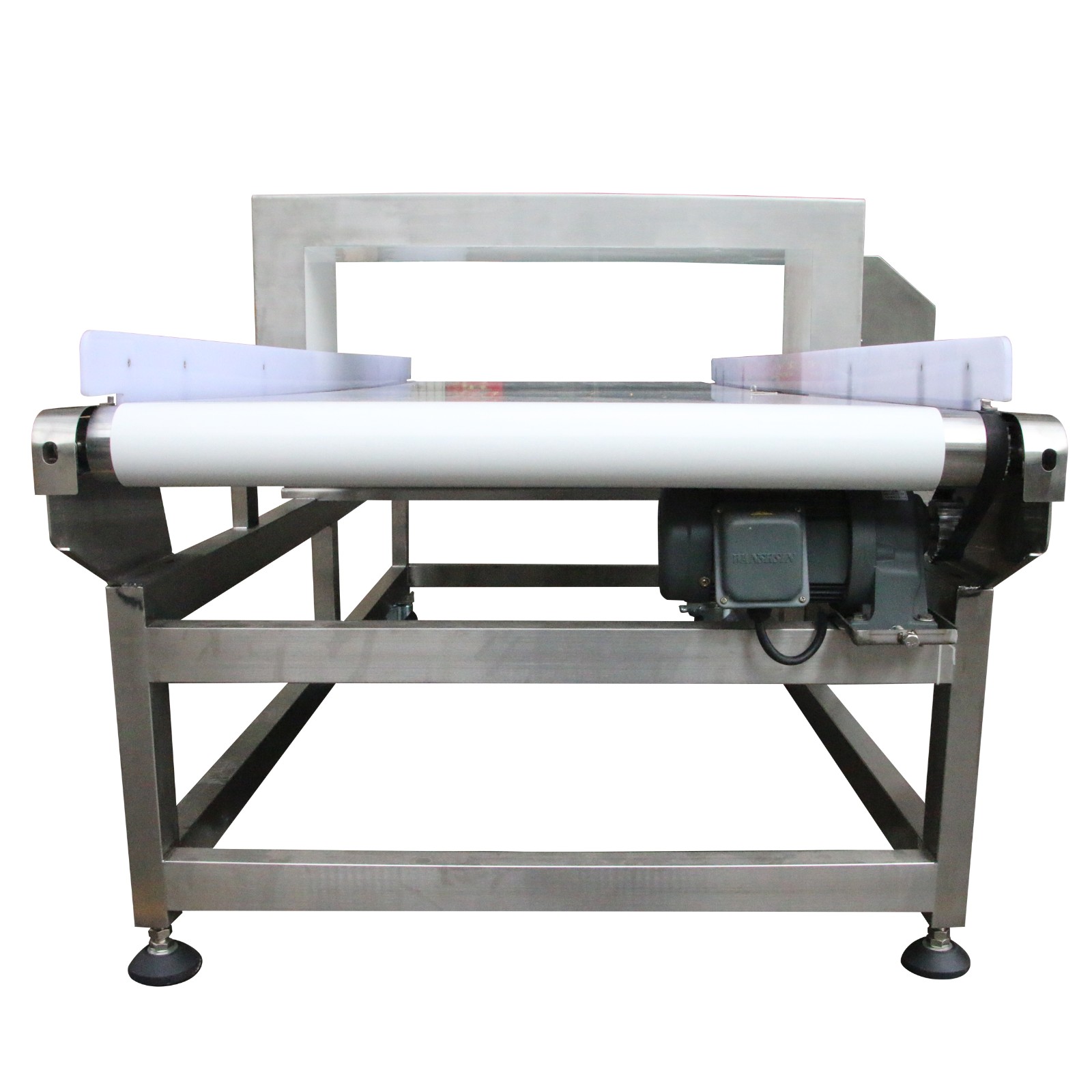

Aluminum package metal detectors are seamlessly integrated into existing food processing lines, becoming an intrinsic component of the production process. The strategic placement of these detectors facilitates real-time detection and rejection of metallic contaminants, preventing their inclusion in the final processed products.

### B. Detection Principle

The fundamental principle behind aluminum package metal detection is based on electromagnetic and magnetic induction. These detectors emit electromagnetic waves that interact with the aluminum packaging. If metallic contaminants are present, they disrupt the electromagnetic field, triggering an immediate detection response.

### C. Automatic Rejection Systems

Upon detection of a metallic contaminant, modern aluminum package metal detectors are equipped with automatic rejection systems. These systems swiftly and precisely eliminate the affected product from the production line, ensuring that only uncontaminated items proceed to subsequent processing stages.

## III. Technological Specifications

### A. Full Range of Aperture Sizes

Aluminum package metal detectors boast a diverse range of aperture sizes, accommodating various package dimensions and configurations. This adaptability ensures comprehensive coverage, regardless of the packaging specifications.

### B. Auto Parameter Setting

Intelligent product learning capabilities empower these systems to automatically set parameters based on the specific characteristics of the packaged products. This self-learning functionality enhances the accuracy and efficiency of metal detection across different items.

### C. Multi-Filtering Algorithm

To enhance interference resistance, aluminum package metal detectors incorporate multi-filtering algorithms. This advanced feature minimizes the impact of external factors, ensuring reliable and consistent metal detection results.

### D. Password-Protected Access

Security is a paramount consideration in food processing. Aluminum package metal detectors prioritize security through password-protected access, preventing unauthorized adjustments to critical settings and maintaining the integrity of the detection process.

### E. Multiple Product Memories

The ability to store and recall multiple product parameters facilitates rapid changeovers between different items on the production line. This flexibility streamlines the operational efficiency of food processing processes.

### F. Comprehensive Metal Detection

Aluminum package metal detection systems excel in detecting various types of metal, including ferrous metals (iron), non-ferrous metals (aluminum, copper), and stainless steel. This broad-spectrum detection capability ensures a thorough screening process.

### G. Optional Rejection Modes

Manufacturers can customize aluminum package metal detection systems based on their specific requirements. Optional rejection modes, such as pneumatic pushers, flippers, drop belts, and belt retractions, provide tailored solutions for diverse processing environments.

### H. Modular Design for Easy Maintenance

The modular design of these systems facilitates quick replacement and straightforward maintenance. This ensures minimal downtime and contributes to the long-term reliability of aluminum package metal detection equipment.

### I. Output Safety Cover

To enhance operational safety, optional output safety covers with gate-open sensors can be integrated. These sensors halt the machine when the cover is open, preventing accidental contact and ensuring a secure operating environment.

### J. Frame Construction

The frame of aluminum package metal detection systems is typically constructed from high-quality materials such as SUS304 stainless steel. This choice of materials, coupled with precision CNC tooling, ensures durability and longevity, even in demanding industrial settings.

## IV. Applications in the Food Processing Industry

### A. Detection in Food Packages

Aluminum package metal detectors are specifically designed to detect metal contaminants in food packages, including those made of aluminum. This application ensures that the final processed products are free from metallic contaminants that could compromise quality and safety.

### B. Electronic Components

Beyond food packaging, aluminum package metal detectors find utility in detecting metal contaminants in electronic components. This is particularly crucial in industries where precision and reliability are paramount, preventing damage to sensitive electronic equipment.

### C. General Packaging

Aluminum package metal detectors are versatile tools that extend beyond specific materials. They are adept at detecting metal contaminants in general packaging, providing a comprehensive solution for various industrial applications.

### D. Other Industries

The applications of aluminum package metal detectors extend beyond the food processing industry. They find utility in pharmaceuticals, cosmetics, chemicals, and more, where the detection of metallic contaminants is critical to product quality and safety.

## V. Advantages of Aluminum Package Metal Detectors

### A. Preservation of Product Quality

The primary advantage of aluminum package metal detectors is their ability to preserve the quality of processed products. By detecting and eliminating metallic contaminants, these detectors contribute to the production of safe

Supplying Excellence in Food Safety - Aluminum Package Metal Detectors**

Elevate food safety standards with our specialized Aluminum Package Metal Detectors designed for the food industry. As a reliable supplier, we provide cutting-edge solutions that ensure the detection of metal contaminants in aluminum-packaged food products.

Advanced Metal Detection Technology**

Our Aluminum Package Metal Detectors feature advanced technology for precise metal detection in aluminum-packaged food. Experience superior accuracy in identifying metallic contaminants, ensuring the safety and quality of your food products.

Customized Solutions for Aluminum Packaging**

Adapt to the unique characteristics of aluminum packaging with our customizable Metal Detectors. Whether handling different sizes, shapes, or thicknesses of aluminum packages, our systems can be tailored to meet the specific requirements of your food processing line.

Efficient and Non-Intrusive Detection**

Ensure efficient and non-intrusive metal detection in aluminum-packaged foods with our specialized detectors. These systems are designed to seamlessly integrate into your production line, contributing to a continuous and smooth workflow.

Compliance with Food Safety Regulations**

Meet and exceed food safety regulations with our Aluminum Package Metal Detectors. Designed to comply with stringent industry standards, these detectors contribute to HACCP and GMP compliance, ensuring the highest level of food safety.

User-Friendly Interface for Seamless Integration**

Simplify operations with our user-friendly interface. Our Aluminum Package Metal Detectors offer clear and intuitive controls, allowing operators to monitor and manage the metal detection process effortlessly, facilitating seamless integration into your food processing environment.

Upgrade your food safety protocols with our Aluminum Package Metal Detectors. Contact us to explore how these advanced systems can contribute to the safety, quality, and compliance of your aluminum-packaged food products.