Contaminant Detection for Plastics Processing

MetalDetectorRejects Problem / Opportunity:

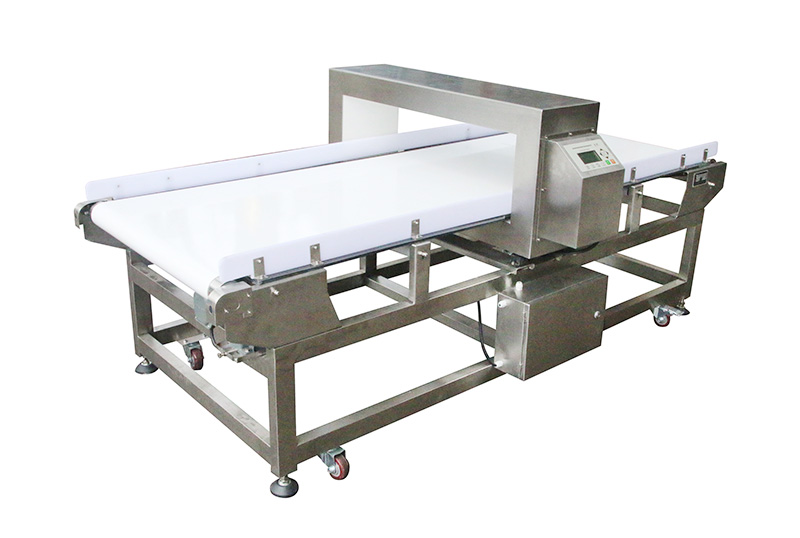

Some of our customers are experts in the recycling of PVC siding and windows. They use a magnet and a metaldetector to remove the metal generated during granulation. While magnets can remove the ferrous metal(attracted to a magnetic), a metaldetectorwas used to detect and remove the non-ferrous metal.Due to the way metaldetectorsfunction, unfortunately they rejectseveral hundred times more plastic materials along with the metalevery time they detect the presence of metal.

Customer Impact:

Although the metaldetectorremoved some of the metal from the granulation stock the process still produced 1,000,000 lbs. of metaldetectorrejectsconsisting of 95% PVC and 5% metal.Now unusable the options available to the customer were as follows:

They should retain the material (which they did for many years).

Toss the material

Export the material "as-is" for less than 20% of the price that clean PVC regrind would fetch in the market.

Solution for Customer

Butler-MacDonald doesn't rely on metaldetectors to remove metal. Evaluated samples proved that the process can separate the material economically and effectively, regardless of its type.

Benefit:

Butler-MacDonald received the material and processed it. We delivered 92% of metal-freePVC regrind. The customer realized the full value of this feed stream and was able to gain approximately. 900,000 lbs. PVC regrind.

Value shouldn't be left behind. We can do so much, you won't believe it - until your call.