Textile Industry

we supply hand held ,tablet,conveyor belt needle detector machines detect broken needles and metal scraps during in garment, textile,toys,shoes industry

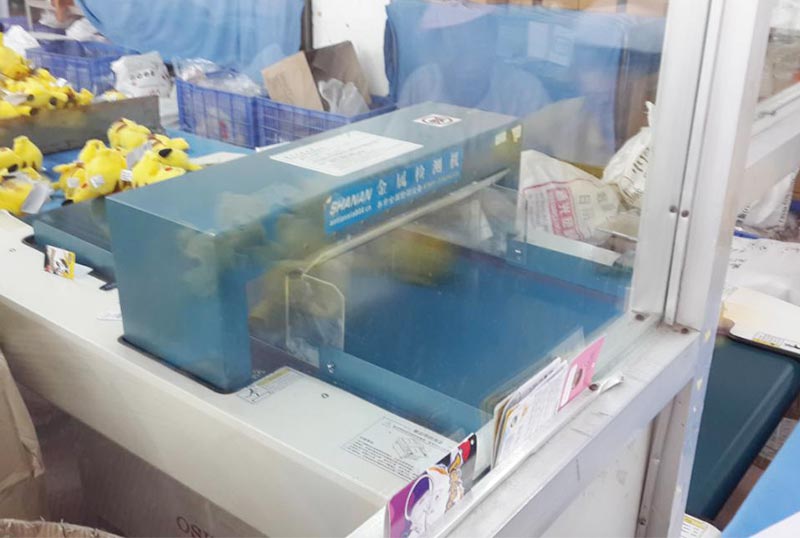

🔹 Metal Needle Detector Machine for Textile Industry Factory China

1. Overview

In the textile and garment industry, ensuring product safety is critical—especially for items such as clothing, underwear, baby wear, shoes, gloves, and bedding. A metal needle detector machine is a specialized inspection system designed to identify and remove broken needles, sewing machine parts, and other metallic fragments that may be accidentally embedded in fabrics during production.

For factories in China’s textile hubs—such as Guangzhou, Shenzhen, Dongguan, and Zhejiang—the adoption of needle detectors is essential for meeting international safety standards and fulfilling export requirements to Japan, Europe, and the USA.

2. Applications in Textile Industry

✅ Garment Production

Detects broken needle tips from sewing machines in shirts, jackets, trousers, underwear, uniforms.

✅ Children’s & Baby Wear

Provides 100% safety assurance by removing any risk of hidden sharp metal pieces.

✅ Shoes & Accessories

Inspects sneakers, gloves, hats, socks, belts, and zippers for needle fragments.

✅ Home Textiles

Used for quilts, cushions, blankets, and bed sheets to prevent dangerous metal contamination.

✅ Export Factories in China

Ensures compliance with Japanese and European buyer standards, where needle detection is mandatory before shipment.

3. Key Features

High Sensitivity – Detects ferrous metals such as broken sewing needles, wire pieces, and steel fragments as small as 0.8mm.

Conveyor System Design – Automatic belt conveyor for continuous inspection of finished textile products.

Multi-Zone Detection – Pinpoints metal location with alarm, light, and automatic stop system.

User-Friendly Interface – Simple operation with sensitivity adjustment and self-learning mode.

Hygienic & Durable Structure – Stainless steel frame and smooth conveyor belt.

Automatic Rejection (Optional) – Flap or pusher system to separate defective products.

Compliance Ready – Meets ISO, CE, HACCP, and Japanese safety standards for textile exports.

4. Benefits for Textile Factories in China

Ensures Safety & Compliance – Prevents hazardous products from reaching consumers.

Supports Export Market – Meets strict foreign buyer inspection requirements.

Protects Brand Reputation – Reduces risk of product recalls and customer complaints.

Boosts Efficiency – Inline conveyor system supports mass production lines in textile factories.

Cost-Effective – Prevents loss caused by rejected shipments in international trade.

5. Typical Products Inspected

Baby clothes, school uniforms, underwear, socks

Jackets, jeans, shirts, fashion apparel

Shoes, gloves, hats, scarves, belts

Quilts, blankets, pillows, cushions

Textile accessories & export-ready finished goods

✅ Conclusion

The Metal Needle Detector Machine for Textile Industry Factories in China is a vital quality assurance tool for garment and textile production. By detecting broken needles and metallic fragments at high sensitivity, it safeguards consumer safety, export compliance, and brand credibility. With robust design, automatic conveyor integration, and international standard compliance, it is the ideal solution for Chinese textile manufacturers supplying both domestic and global markets.

viking VFG Series needle detector mainly designed for the inspection of wide, thin products and found out that broken needles that may lost in the garments textiles and hurt human body.

Especially for the underwear. Children products and so on.

It can found the broken needles (Ferrous from 0.8mm till different size).

Some international retailer have strictly rules on the needle detector.

For example the Walmart FCCA audit all request have such a machine from us.