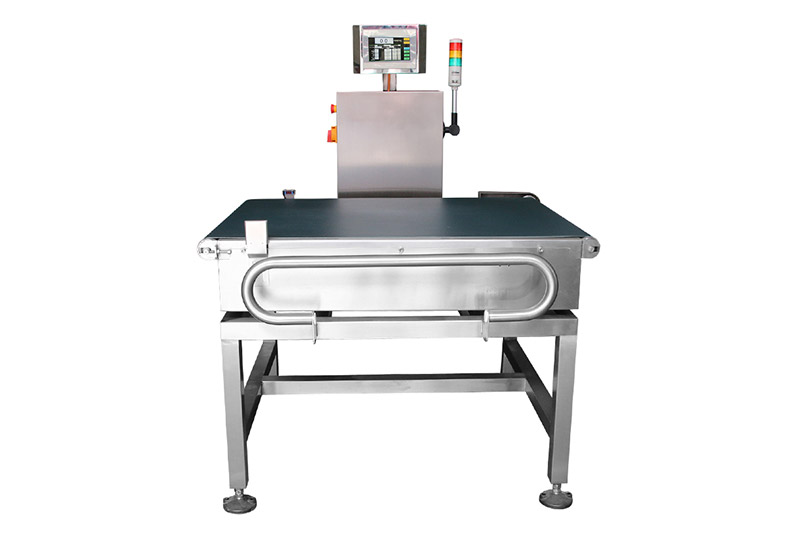

checkweigher system

Introducing Our High-Accuracy Automatic Rejection Checkweigher System

In the world of manufacturing and quality control, precision is everything. We are proud to present our High-Accuracy Automatic Rejection Checkweigher System—a cutting-edge solution designed to ensure that your products meet the highest standards of quality, every time.

**Key Features and Benefits:**

- **Precise Weight Verification:** Our Automatic Rejection Checkweigher is engineered to provide accurate and real-time weight verification for your products. This precision guarantees that every item adheres to the specified weight criteria, minimizing costly production errors.

- **Seamless Integration:** Designed for hassle-free integration into your existing production line, our checkweigher operates seamlessly without causing disruptions. This ensures that your manufacturing process remains efficient and streamlined.

- **Quality Control Enhancement:** With advanced technology at its core, our system empowers you to maintain exceptional quality control. Say goodbye to inaccuracies in product weight, and in turn, ensure customer satisfaction and brand reputation.

- **Customizable Parameters:** Tailor the checkweigher's settings to align with your unique production needs. Configure weight thresholds, tolerance levels, and rejection criteria to meet your quality assurance standards.

- **User-Friendly Interface:** An intuitive user interface simplifies operation and monitoring, reducing the learning curve for your operators and boosting overall efficiency.

- **Comprehensive Data Management:** Our system offers robust data logging and reporting capabilities, enabling you to track production metrics, detect trends, and maintain meticulous quality control records.

- **Rugged Durability:** Built for industrial environments, our Automatic Rejection Checkweigher is constructed to withstand the rigors of continuous use, ensuring consistent performance even in demanding conditions.

**Why Choose Our Automatic Rejection Checkweigher:**

- **Proven Excellence:** Backed by a track record of delivering high-precision checkweigher solutions to diverse industries, we are renowned for enhancing product quality and manufacturing efficiency.

- **Global Trust:** Manufacturers worldwide trust our solutions to maintain product quality and ensure compliance with stringent weight standards.

- **Responsive Customer Support:** Our dedicated customer support team is always ready to assist with installation, maintenance, and technical support, ensuring the smooth operation of your production line.

Elevate the precision and efficiency of your production processes with our High-Accuracy Automatic Rejection Checkweigher System. Contact us today to explore our offerings, pricing, and how our advanced system can contribute to the success of your manufacturing operations. Your quality is our commitment, and we're here to help you uphold it.

Checkweighers: Ensuring Compliance and Efficiency**

Checkweighers play a vital role in ensuring adherence to label weight regulations and reducing product giveaway. Our advanced checkweighers are here to help you maintain packaging accuracy, reduce customer complaints, optimize production, and minimize product wastage.

Key Features and Structural Advantages:**

1. **Precise Digital Signal Processing:** Our checkweighers employ advanced digital signal processing, delivering high-speed and consistent weighing results. You can rely on their accuracy to meet regulatory requirements.

2. **User-Friendly Interface:** Equipped with a user-friendly liquid crystal touchscreen, these checkweighers are exceptionally easy to operate. Streamline your processes without sacrificing precision.

3. **Self-Diagnostic Function:** These systems come with a built-in self-diagnostic function. They can detect issues such as ROM/RAM errors or A/D light electric tube malfunctions, ensuring uninterrupted performance.

Applications of Checkweighers:**

Our checkweighers are versatile and can be used for:

- Weighing individual products and verifying whether they meet the target weight.

- Sorting and eliminating non-standard products from the production line.

**Additional Features:**

- **Robust Stainless Steel Build:** Crafted from solid SUS304 stainless steel, our checkweighers deliver exceptional performance and durability.

- **Tool-Free Belt Disassembly:** Cleaning is a breeze with belt disassembly that requires no tools, saving you time and effort.

- **Multiple Rejecter Options:** Choose from various rejecter systems, including automatic stop with sound and light, air blast, or pneumatic push rod, to suit your specific needs.

- **Emergency Stop Button:** We prioritize safety in the workplace, which is why our checkweighers come equipped with an emergency stop button, ensuring safe working conditions.

Our checkweighers are designed to be reliable, efficient, and user-friendly, allowing you to maintain compliance with weight regulations and reduce product giveaway. With their solid stainless steel construction, tool-free maintenance, and multiple rejecter options, you can trust our checkweighers to optimize your production processes. Contact us today to explore how our checkweigher solutions can benefit your operations. Your accuracy and efficiency are our commitment.

VC-10 | VC-15 | VC-22 | VC-30 | VC-40 | VC-25(Two belt) | VC-100 | |

Model Name | |||||||

Weight range (g) | 3-100 | 3-300 | 10-1200 | 30-3000 | 50-1000 | 50g-25kg | 1kg-100kg |

Mini weight accuracy (g) | ±0.1 | ±0.3 | ±0.5 | ±1 | ±0.5 | ±5g | ±10g |

Mini screen value (g) | 0.01 | 0.1 | 0.1 | 0.1 | 0.1 | 0.5 | 1g |

Max weigh speed (Bags /Minute ) | 20 | 330 | 210 | 180 | 180 | 50 | 20 |

Belt speed | 0 | 16-118 | 13-96 | 13-96 | 13-96 | 13-78 | 3-15 |

(Meter/minute ) | |||||||

Suitable product length (mm) | - | 60-180mm | 60-300mm | 60-420mm | 60-500mm | 60-420mm | - |

Suitable product width (mm) | - | 30-150mm | 30-200mm | 30-250mm | 30-400mm | 30-380mm | - |

Suitable product height (mm) | - | 10-130mm | 10-200mm | 10-330mm | 10-330mm | 10-430mm | - |

Weigh zone size (mm L*W) | - | 270*110 | 400*220 | 500*300 | 500*400 | 800*600 | 1000*800 |

Note | Non-standard (without belt) | High accuracy | Small common model | Customized model | Customized model | Common model for Box | Roller end belt |

Reject device optional | Pin Rod /Push rod /air blast /divided flow /drop down /flap drop (Optional ) | ||||||

Optional | |||||||