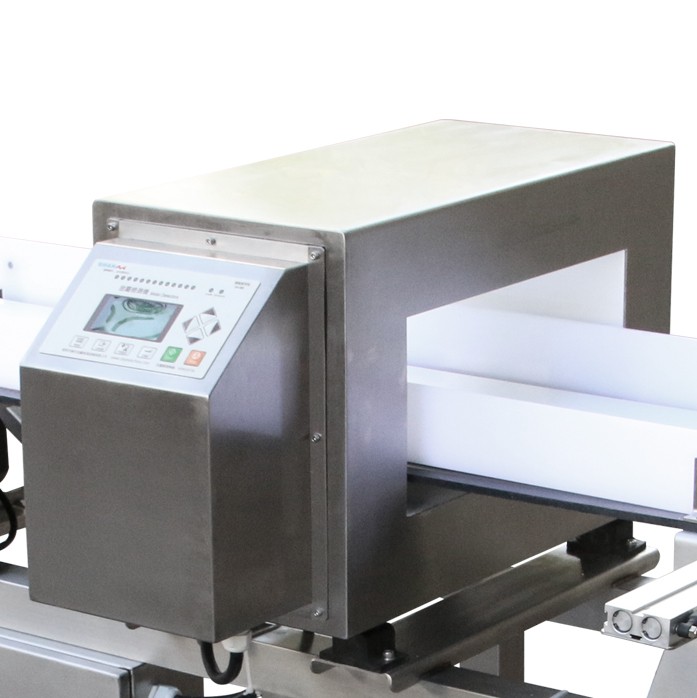

Stainless steel metal detector in food industry

Stainless steel metal detector in food industry

Metal detection in food industry

Metal detection has become an essential part of the food industry. Food safety is a major concern for consumers,

and metal contamination can make your product unsafe to eat. The metal detector detects the presence of metals in

food and other products through different methods.

Magnetic and non magnetic metal detector

There are three main methods for detecting metal in a food product: free fall, magnetic detection and infrared detection. These methods depend on the types of metals that you want to detect. If you need to detect stainless steel or other types of metals that are not magnetic, then you will need an infrared detector. If you want to detect non-metallic objects such as coins or nails then using a magnetic detector would be best suited for your needs.

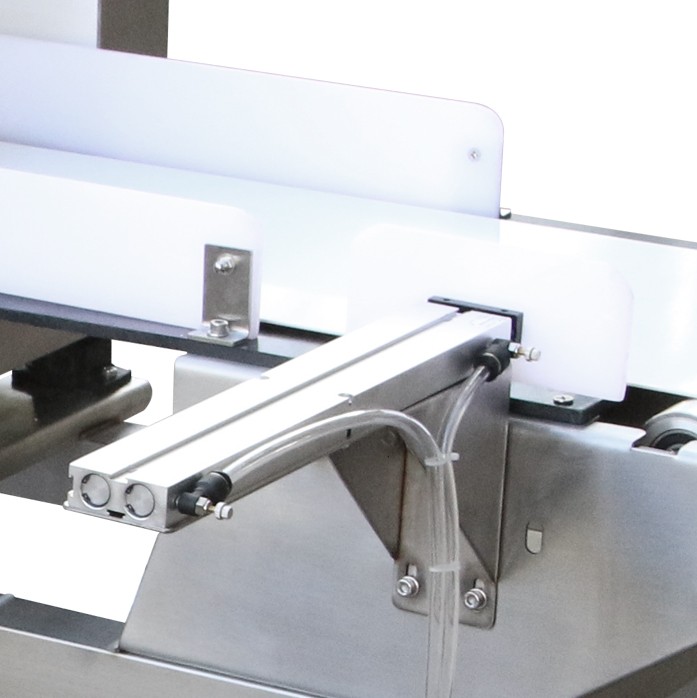

Food Industry Stainless steel metal detector

Metal contamination is a serious problem for the food industry. It can occur at any stage of the production process, from raw materials to finished products.

Stainless steel is the most commonly contaminated metal, but other metals may also be found in food products. In general,

stainless steel is more resistant to corrosion than other metals, so it is more likely to create problems for the food industry.

Quality and safety metal detector

Stainless steel metal detectors are used to detect whether or not stainless steel is present in a product or ingredient. This allows companies to ensure that their products are free from harmful contaminants that could affect quality and safety. Food manufacturers can use this information to make sure that they're producing safe foods and avoiding any potential health risks caused by food additives or contaminants during processing stages such as packaging or cooking.

For example: if you wanted to make sure your spaghetti sauce was free from lead contamination, you could use a high-quality stainless steel metal detector to scan your sauce before serving it up at home!

Stainless steel is a metal that is used in products like food processing, the medical industry, and the automotive industry. It is a very useful material because it can withstand high temperatures without becoming brittle or losing its shape.

Food processing industry metal detector

In a food processing facility, stainless steel is used in the production of many different products. Some of these include:

-Foods such as meat, dairy products, and even fruit

-Vegetables (such as potatoes)

-Fruits (such as apples)

-Frozen foods (such as ice cream)

-Soup bases and dressings