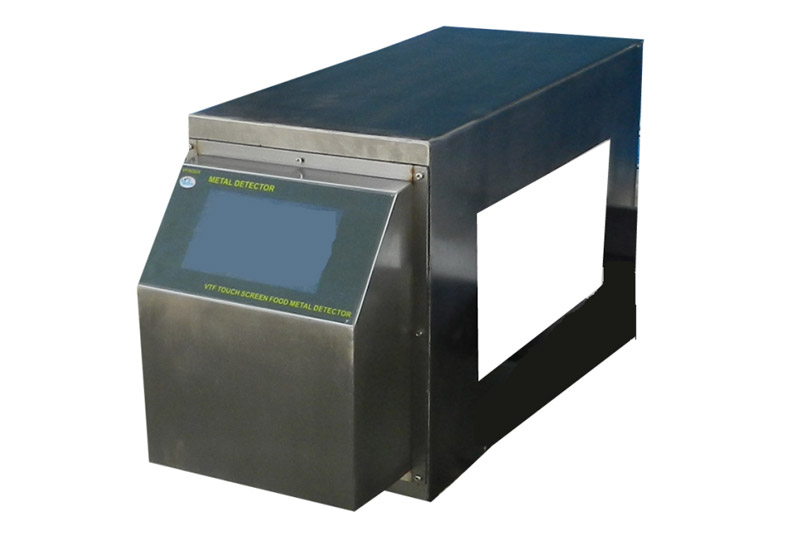

High accurate small tunnel size digital food metal detector

Introduction:

In the realm of food processing and packaging, ensuring the safety and quality of products is paramount. Metal detectors play a crucial role in identifying and eliminating metallic contaminants, safeguarding consumers from potential health risks. This comprehensive exploration focuses on the introduction and applications of conveyor belt metal detectors in the food industry, with a specific emphasis on the innovative offerings from DongGuan Viking Metal Detectors.

I. DongGuan Viking Metal Detectors: Pioneers in Conveyor Belt Metal Detection

1. **Versatility Across Conveyor Systems:**

DongGuan Viking Metal Detectors specializes in manufacturing metal detectors tailored for deployment on conveyors, gravity feeds, and pipeline systems. Their detectors efficiently identify metallic contaminants, including aluminum, iron, and steel, making them versatile for a wide range of applications in the food industry.

2. **Rectangular Head Design for Conveyor Belt Scanning:**

The hallmark of DongGuan Viking's metal detectors is the rectangular head design, specifically engineered for scanning products transported via conveyor belts during food processing and packaging. This design ensures comprehensive coverage, leaving no room for undetected contaminants.

3. **All-in-One Solution with Vector Conveyor:**

DongGuan Viking provides an all-in-one solution that includes the Vector Conveyor, simplifying installation and maximizing system performance. This integrated approach streamlines the deployment of metal detectors in the food processing line, contributing to the overall efficiency of the system.

4. **Customization Options for Construction:**

Clients can choose from a variety of standard detectors offered by DongGuan Viking or opt for customized solutions with a range of construction options. These include stainless steel, painted aluminum, and extra-rugged BSH casings, allowing for flexibility in meeting diverse industry requirements.

II. Detection of Metallic Contaminants in Food Processing:

1. **Case Study: Discovery on an Abandoned Conveyor Belt:**

Recently, an object of interest was discovered on an abandoned conveyor belt in a food processing factory. The metal detector efficiently detected small amounts of metal on the object, showcasing its exceptional sensitivity. This incident underscores the critical role of metal detectors in preventing health risks associated with metal contamination in food.

2. **Wide Range of Food-Grade Metal Detectors:**

DongGuan Viking offers a diverse range of food-grade metal detectors in various formats. These include gravity-fed, pharmaceutical, flow-through, biscuit, and conveyorized metal detectors. Each type boasts outstanding stability and sensitivity, making them suitable for integration into existing production lines.

3. **Identifying Various Metal Types:**

Metal detectors for the food industry can identify a spectrum of metals, including stainless steel, ferrous metals (cast iron, mild steel), and non-ferrous materials (copper, lead, aluminum). This capability ensures a comprehensive screening process, leaving no room for undetected contaminants.

III. Metal Detectors in HACCP-Certified Food Industry:

1. **Role of HACCP in Metal Detection:**

Hazard Analysis Critical Control Points (HACCP) is a crucial framework for preventing faults in the food industry. Metal detection plays a pivotal role in HACCP, serving as a vital "physical" point of control to mitigate the potential health risks associated with metal contamination.

2. **Critical Parameters for Calibration:**

Detachability is a critical parameter for calibrating metal detectors to the smallest metal test balls. Good Manufacturing Practice (GMP) and state-of-the-art standards must be met to ensure products are free from metal contaminants. Modern metal detectors, such as those from DongGuan Viking, exhibit excellent detection capabilities.

3. **Setting Critical Limit Values:**

Establishing critical limit values is imperative for reliable and stable operation of metal detectors. These values ensure that the detectors operate without false alarms, maintaining a balance between sensitivity and specificity in metal detection.

4. **Preventive Maintenance and Corrective Actions:**

Preventive maintenance is a key aspect of ensuring the consistent performance of metal detectors. Additionally, defined corrective actions must be implemented after metal detection incidents, emphasizing the importance of a well-rounded approach to food safety.

IV. Product Effects in Food Metal Detectors:

1. **Understanding Product Effect:**

Product effect refers to the natural conductivity of a food product and its impact on the metal detector system. Even non-metallic products are subject to product effect, necessitating a nuanced approach to metal detection.

2. **Conductivity as a Detection Mechanism:**

Metal detectors for food utilize conductivity as a means to detect contaminants. Naturally conductive products may trigger the metal detector when passing through, and those with high levels of salt, fat, or moisture exhibit higher product effects. Choosing the right system is crucial for products with high conductivity.

3. **Multi-Frequency Inspection for Optimization:**

Some metal detectors, like the RMD Series High Configuration Metal Detectors by Viking Packsys, employ multi-frequency inspection. This technology allows operators to adjust the frequency of inspection, optimizing sensitivity for more conductive products while minimizing product effects.

4. **X-Ray Inspection for High Product Effect Cases:**

Products with excessive product effects may be better suited for x-ray inspection systems. Unlike metal detectors, x-ray systems are not affected by product changes and do not experience product effects, making them ideal for certain applications.

V. Aluminum Detection in the Food Industry:

1. **Significance of Aluminum Detection:**

While food processing primarily involves ferrous, nonferrous, and stainless steel metals, instances of aluminum introduction may occur. Detecting aluminum is crucial, and metal detectors must be effective in identifying this non-ferrous, low-density metal.

2. **Challenges in Aluminum Detection:**

Aluminum, being significantly less dense than the brass standards used for testing metal detectors, presents challenges in detection. Its non-ferrous nature and low density require specialized detection mechanisms to identify it effectively.

3. **Conductivity of Aluminum:**

The conductivity of aluminum, similar to brass, enables metal detectors to detect it in smaller quantities. This is a unique characteristic that distinguishes aluminum detection capabilities, making food-grade metal detectors the preferred choice for detecting this metal in most foods.

Conclusion:

In conclusion, the introduction of conveyor belt metal detectors by DongGuan Viking Metal Detectors marks a significant stride in ensuring the safety and quality of food products in the processing and packaging industry. These advanced metal detectors offer versatility, customization options, and robust detection capabilities, contributing to the overall efficiency of food safety protocols. From their role in HACCP compliance to addressing product effects and detecting challenging metals like aluminum, these metal detectors exemplify a commitment to advancing food safety standards. As the food industry continues to evolve, innovative solutions like conveyor belt metal detectors become indispensable in safeguarding consumers and upholding the highest standards of quality and safety.

Short specifications of metal detector

*Self-frequency adjustment. You can select from many operating frequencies, depending on your product style.

*Automatic adjustment. Stable features.

*Can recognize different types and products.

*Can store about 100 product parameters data. Easy for different production line shifts.

*Can the belt height be adjusted according to customer production lines to ensure butt-joint to any other equipment.

*Two digital collections line keep it good performance.

* It has a full digital touch screen that makes it easy to use.

* Special design for strong anti-interference function for harsh production environment.

* Super performance and long-lasting service life thanks to its high standard shake-proof.

*Improve design. Tap the probe to trigger an alarm.

Operators can clean the equipment easily with the help of the succinctly detached framework.

The principle advantages of a tunnel metal detector

Tunnel detectors with integrated electronic evaluation electronics can be fitted to conveyer belts to check the goods and protect the technologies.

All metal particles can be detected. This includes both the off-shell and inclusion-shaped particles.

Metals can be detected accurately and most reliably.

Simple operation.

Minimal dimensions (reduction in the area where metal objects can be found)

It meets the requirements of HACCP, IFS and BRC quality systems.

Details parameters of the foodmetaldetector

| Model | FSD series | ||||||||

| Machine specification | Normal machine | Customized width | |||||||

| (mm)Detection Width | 400 | 300 customized | |||||||

| (mm)Detection Height | 100 | 120 | 150 | 200 | 250 | 300 | 350 | 400 | |

| Detection Sensitivity | Fe(Φmm) | ≥0.6 | ≥0.8 | ≥1.0 | ≥1.2 | ≥1.5 | ≥2.0 | ≥2.5 | ≥3.0 |

| Non-Fe(Φmm) | ≥1.0 | ≥1.2 | ≥1.5 | ≥2.5 | ≥3.0 | ≥3.5 | ≥4.0 | ≥4.5 | |

| 304Sus(Φmm) | ≥1.2 | ≥1.5 | ≥2.0 | ≥2.5 | ≥3.0 | ≥3.5 | ≥4.0 | ≥4.5 | |

| Alarm and rejector system | Automatic stop by alarm and sound or push rod or falling drop | ||||||||

| Machine structure | Full structure takes of stainless 304 | ||||||||

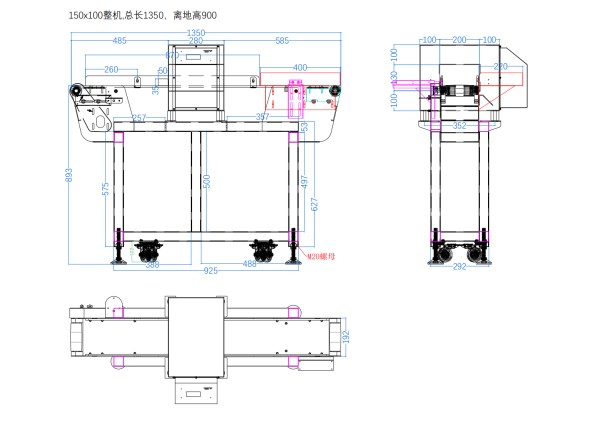

| Machine size (mm) | L1520mm×W830mm×H1000mm if customized it will according to customized size | ||||||||

| Machine weight | Around 250KG if customized the weight will different | ||||||||

| Voltage and power | 220V 50Hz 90W | ||||||||

| Load ability | 5-25KG conveyor belt running speed: 25-30m/min or customized various | ||||||||

| Height from the earth | 650mm±50mm can customized | ||||||||

| Note: Normal size machine have stocks. Unnormal size machine have to customized | |||||||||

CAD drawing reference of metal detector in food

Rejection system of metal detectors

Optional reject 1 :Push rod

Optional 2 flap drop

Optional 3 Air blast