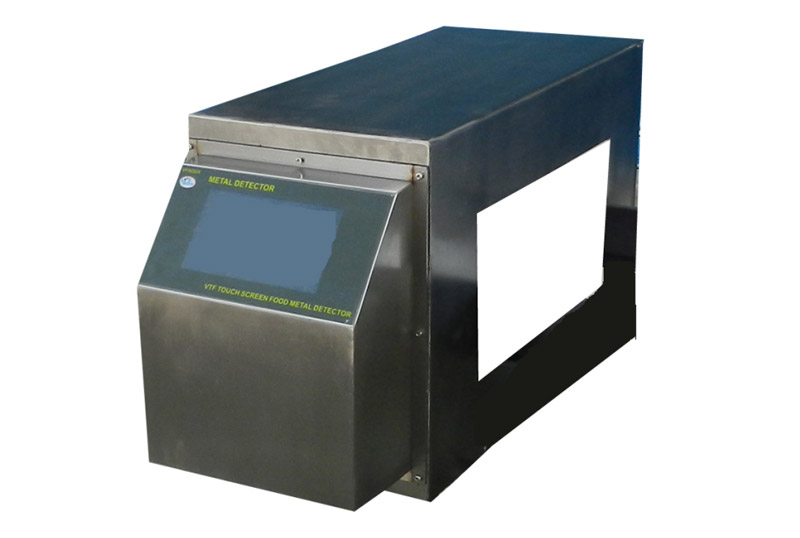

Food detection tunnel metal detector head

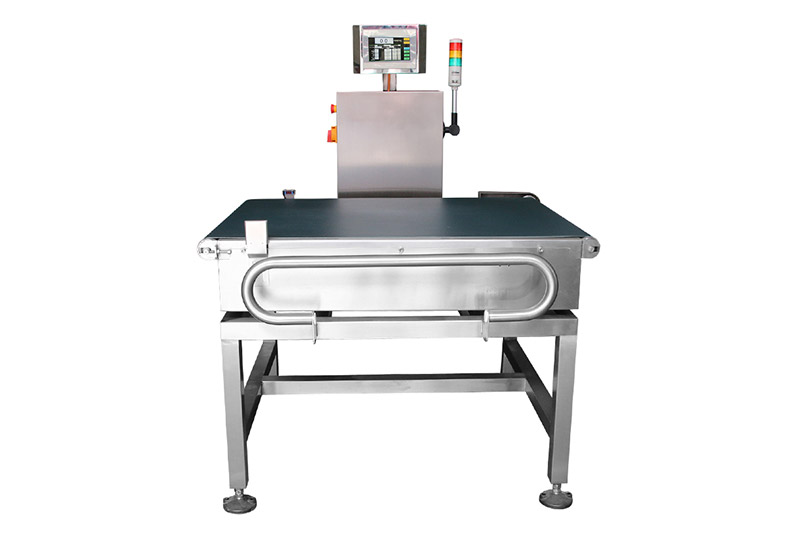

Food production line metal detector head

The food detection tunnel metal detector head for the production line is a new type of detector head that can detect the presence of metals in different types of food. This device can detect the presence of heavy metals such as lead and mercury, as well as lighter metals like copper, zinc, and iron.

The product is made with high-quality materials and has been tested by several customers. It has been used successfully in various applications across different industries such as mining, pharmaceuticals, food & beverages, and many more. The device is easy to use and comes with an integrated software developed by our experts that helps you choose the best settings according to your needs.

what is a metal detector head?

which is the actual part of the machine that allows the product to pass through for inspection, is called the metal detector head. These can be used to add to an existing conveyor, or manually. Metal detectors detect tiny pieces of metal within a container or package. They are typically installed on a processing line or packaging to ensure that the products do not move unintentionally. The type and type of product determine which detector is needed.

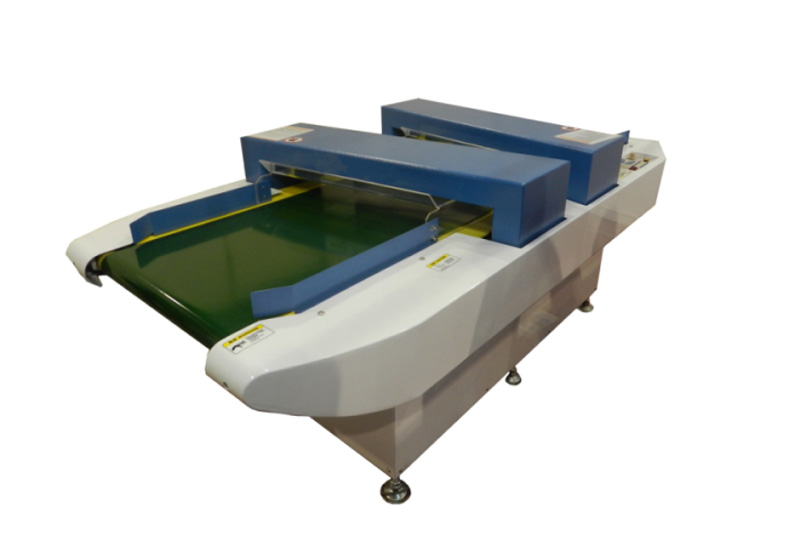

General features of the metal detector head

*Self-frequency adjustment. You can choose from a range of operating frequencies depending on the product style.

*Automatic adjustment. Stable features.

*High sensitivity and self-learning. Can recognize different types of products.

*Can store and record about 100 product parameters.

*It is possible to adjust the belt height to achieve butt-joint with other equipment, depending on customer production line design.

Its good performance is maintained by the two digital collection lines.

It is simple to use thanks to the full digital touch screen.

* Special design for strong anti-interference function for harsh production environment.

* Superior performance and durability.

*Improve design, keep it Zero false alarm when you tap the probe.

Operators will find it simple to clean the equipment with the *succinctly removable framework design.

Principle benefits of a metal detector head for the food industry

Tunnel detectors with integrated evaluation electronics can be installed on the conveyor belts to inspect the goods or protect the technologies.

All metal particles have been detected. These include both off-shell and inorganic particles.

Maximum accuracy and reliability in metal detection

Simple operation.

Minimum Dimensional requirements (reduction in the size of the metal object that can occur in)

It complies with the HACCP/IFSP, BRC, and SQF quality standards.

| Model | VMS-3 | ||||||||

| Machine specification | Normal machine | Customized width | |||||||

| (mm)Detection Width | 400 | 400 customized | |||||||

| (mm)Detection Height | 100 | 120 | 150 | 200 | 250 | 300 | 350 | 400 | |

| Detection Sensitivity | Fe(Φmm) | ≥0.6 | ≥0.8 | ≥1.0 | ≥1.2 | ≥1.5 | ≥2.0 | ≥2.5 | ≥3.0 |

| Non-Fe(Φmm) | ≥1.0 | ≥1.2 | ≥1.5 | ≥2.5 | ≥3.0 | ≥3.5 | ≥4.0 | ≥4.5 | |

| 304Sus(Φmm) | ≥1.2 | ≥1.5 | ≥2.0 | ≥2.5 | ≥3.0 | ≥3.5 | ≥4.0 | ≥4.5 | |

| Alarm and rejector system | Alarm by sound and light.automatic control signal output | ||||||||

| Machine structure | The full structure takes of stainless 304 | ||||||||

| Machine weight | Around 100KG if customized the weight will different | ||||||||

| Voltage and power | 110V-220V 50Hz 90W | ||||||||

| Note : Normal size machines have stocks. Unnormal size machines have to be customized | |||||||||