IMD-P In-line Metal Detector for Gravity Feed

Revolutionizing Gravity Applications with Metal Detector IMD Series

Discover the epitome of metal detection innovation with the Metal Detector IMD Series – the first DSP metal detector with Intellectual Property Rights in China. Tailored for gravity applications, this advanced system sets new standards in contaminant detection across diverse industries.

Unprecedented Contaminant Detection

The Metal Detector IMD Series is engineered to detect all metal contaminants, ensuring the highest level of product safety. From packaged to non-packaged food items, it excels in identifying ferrous metals (Fe), non-ferrous metals like copper and aluminum, as well as stainless steel, with unmatched precision.

Versatility Across Industries

Designed to cater to a spectrum of industries, the Metal Detector IMD Series is the ideal solution for aquatic products, meat & poultry, salted products, pastry, nuts, vegetables, chemical raw materials, pharmacy, cosmetics, toys, and more. Its adaptability makes it a crucial asset in maintaining product integrity across various production processes.

Advanced DSP Technology

Powered by Digital Signal Processing (DSP) technology, this metal detector series stands out as a pioneer with Intellectual Property Rights in China. The advanced DSP ensures unparalleled accuracy in contaminant detection, reinforcing its position as an industry leader.

Precision in Gravity Applications

Specifically crafted for gravity applications, the Metal Detector IMD Series guarantees precise and efficient metal contaminant screening in gravity-fed processes. This ensures the integrity of bulk materials and vertical pipelines, making it an indispensable tool for industries relying on gravity-driven production lines.

Comprehensive Metal Contaminant Screening

Experience comprehensive metal detection capabilities that go beyond the ordinary. The Metal Detector IMD Series not only identifies ferrous and non-ferrous metals but also excels in stainless steel detection. This level of thorough screening enhances the safety and compliance of your production processes.

Elevating Product Safety in Pharmaceuticals

In the pharmaceutical industry, product safety is paramount. The Metal Detector IMD Series, with its advanced technology and compliance with Good Manufacturing Practice (GMP) standards, ensures that pharmaceutical raw materials and finished products are free from metal contaminants, upholding the highest quality standards.

Seamless Integration into Production Lines**

One of the hallmarks of the Metal Detector IMD Series is its seamless integration into production lines. Whether it's a gravity conveyor system or vertical pipelines, this detector adapts effortlessly, providing continuous, automated inline inspection.

Bulk Handling Excellence

For industries dealing with bulk materials, the Metal Detector IMD Series excels in bulk handling. Its high-capacity metal detection capabilities make it an invaluable asset in maintaining the purity and safety of bulk products.

In conclusion, the Metal Detector IMD Series redefines gravity applications by combining groundbreaking DSP technology with unmatched versatility. Its role in ensuring contaminant-free production across various industries underscores its significance in elevating product safety, compliance, and overall manufacturing excellence. Invest in the Metal Detector IMD Series to experience a new era in gravity-driven metal detection.

Gravity Fall Metal Detector

With compact design and small occupied space, this type of metal detector is suitable for the detection of powder, granule or other forms of bulk products

Product Features

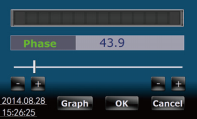

Stable and High Sensitivity

●Special phase adjusting technology

●High sensitivity with stable perf rmance

●Auto balance function

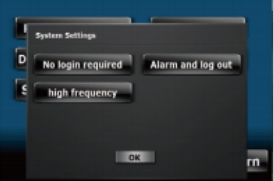

High Configuration

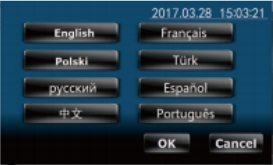

●Touch screen

●USB Port

●Dual-frequency

●Customized re ecter system

●Different surface treatment

User-friendly Function

●Multi languages

●Customization

●Large memory capacity

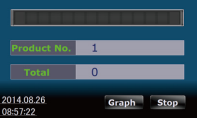

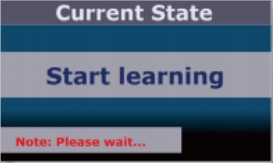

Auto-learning Function

●Auto-learning product character

●Finish auto-learning process very soon

Product Specifications

Model | IMD-P | ||||||

Detection Diameter (mm) | Detection capacity t/h2 | Rejecter Mode | pressure Requirement | power supply | Main Material | Sensitivity 1Φd (mm) | |

Fe | SUS | ||||||

50 | Automatic flap rejecter

| 0. 5Mpa≥ | AC220V (optional) | stainless steel (SUS304) | 0.5 | 1.2 | |

75 | 3 | 0.5 | 1.2 | ||||

100 | 5 | 0. 7 | 1.5 | ||||

150 | 5 | 0. 7 | 1.5 | ||||

Note:

1. The technical parameter above namely is the result of sensitivity by detecting only the test sample inside the pipe. The sensitivity would be affected according to the products being detected and working condition.

2. Detecting capacity per hour is related with product weight, the value of the table is according to the density of water (1000kglm3) ·

3. Requirements for different sizes by customers can be fulfilled![]()

Product Configuration