metal detector for Rubber tire and seal

metal detector for rubber and seal materials processing industry

The Rubber Tire and Seal Materials Processing Industrial Metal Detectors are designed to detect metals in rubber and seal materials. They are used for metal detection in the tire and seal industry, as well as other industries where metal detection is needed.

The Rubber Tire and Seal Materials Processing Industrial Metal Detectors have an auto-ranging feature that allows them to detect metals at a distance of up to 10 feet away. This makes it possible for these detectors to be used in situations where there is no free space around them, such as inside rolling stock or vehicles.

The Rubber Tire and Seal Materials Processing Industrial Metal Detectors can also be used in areas where there is a risk of people getting hurt because they are too close to moving parts. This makes them ideal for use around machinery, etc.

The risk metals in rubber and seal materials processing industry

The risk metals in rubber processing industry include ferrous, non-ferrous, and metal scraps. Ferrous

metals include steel, iron and aluminum. Non-ferrous metals include copper, lead, zinc, tin and nickel. Metal scraps are materials that contain a

mixture of all these metals.

why it is necessary for metal detection in rubber industry

Metal detection is necessary in the rubber industry for two reasons. First, because of the nature of rubber itself, which can contain or be contaminated with metals such as ferrous or non-ferrous, machine wastage scrapes during machine processing

Second, because of the presence of certain chemicals used in the manufacturing process that may contain trace amounts of these metals.

Metal detection is a necessary step in rubber manufacturing because it provides safety for the workers and ensures that there are no dangerous objects in the product. Safety is critical in any industry, but especially so in one that involves the use of chemicals and sharp objects.

Rubber manufacturing is a process that requires specialized equipment and skills, which means that it is dangerous for employees to work without proper protection. Metal detectors help ensure that employees are safe from injury due to mishandling of machinery or cutting tools.

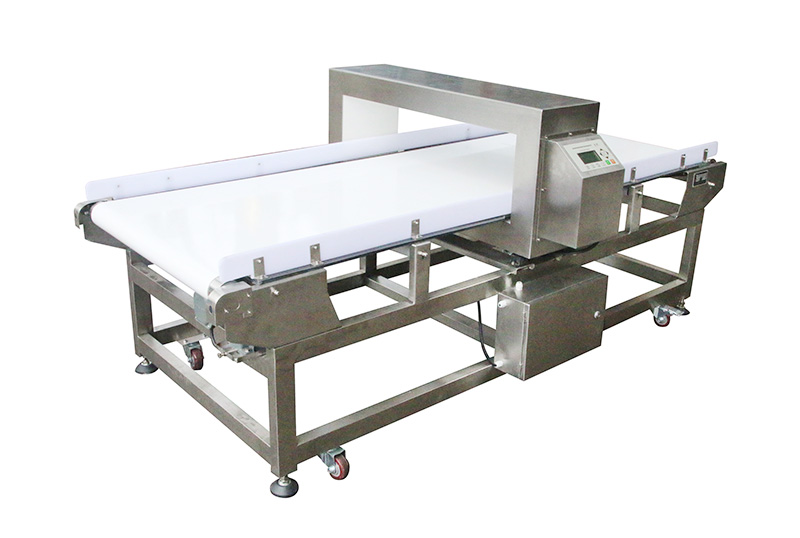

General pecifications :

1. Stable Structure of Metal Detector Made by Stainless Steel

The metal detector is made by stainless steel, which is able to keep stable structure, and it can be used for long time.

2. Adjustable Speed Motors Make Sure Meet Different Capacity of Detection Request

The speed of detection motor can be adjusted as per your requirement. The speed of detection motor can be adjusted as per your requirement. This can help you to meet different capacity of detection request.

3. Automatic Rejection System

When there is trace of metal in the merchandise, the automatic rejection system will automatically stop the conveyor belt to avoid any harm to the merchandise. This can help you to meet different capacity of detection request

4. Digital Control System

The digital control system makes sure that all equipment is working properly and the machine does not go out-of-order due to any reason

5. PU Grade Industrial Conveyor Belt

PU grade industrial conveyor belt is designed for heavy duty applications, such as in food processing plants or other industries with high volume processing requirements

6. Customized Belt Height To Connect You Production Line