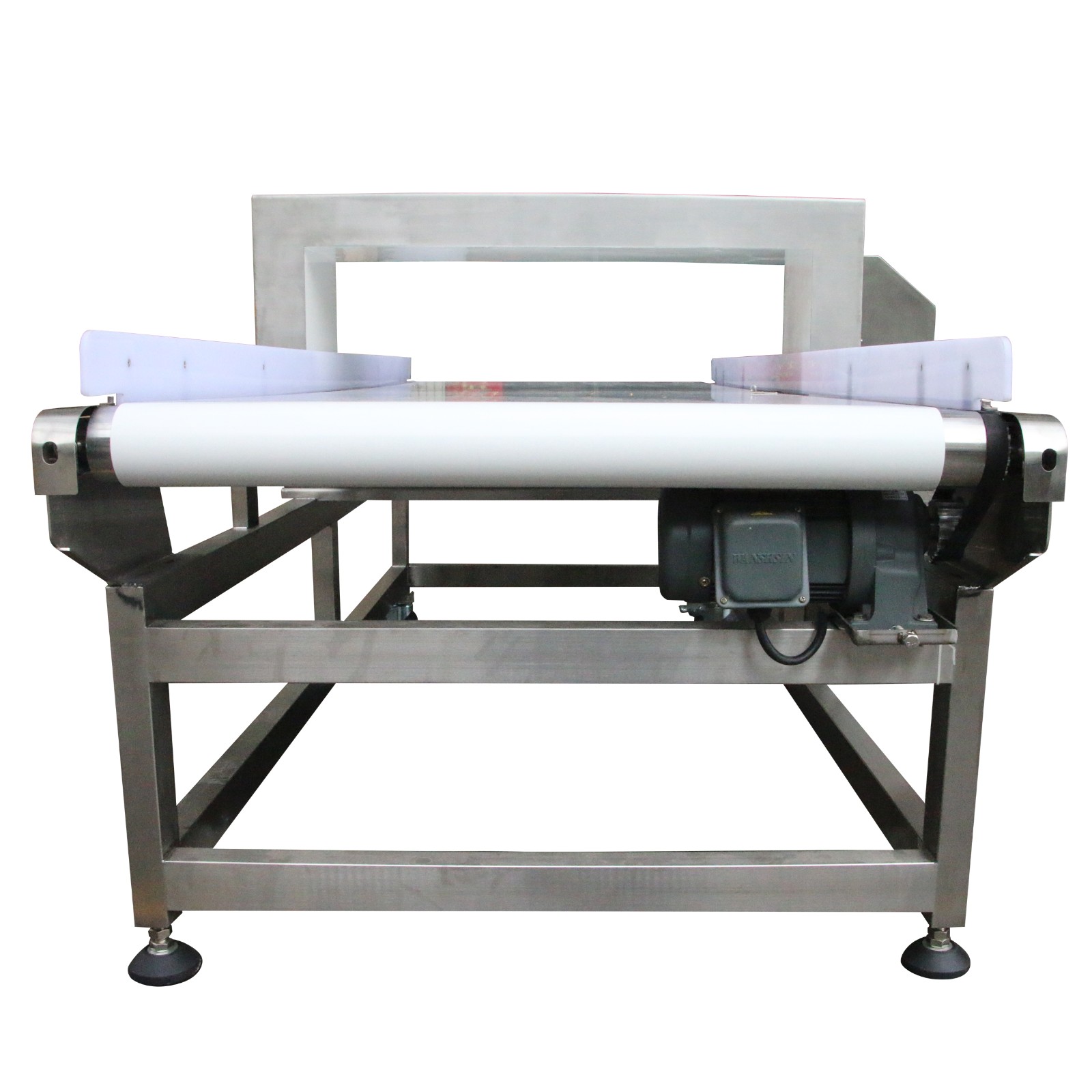

ferrous materials metal detector

ferrous and non-ferrous metal detector in food industry

The ferrous non ferrous metal detector is a tool used to detect metals in food, packaging and other products. The metal detector is used to check for the presence of metals that are not supposed to be present in the product. The metal detector can be used for different types of products like food and beverages, pharmaceuticals, medical devices, electronics and many more.

The metal detector works by sending an electromagnetic wave into the product and then detecting the reflected waves from different objects in the product. It uses this information to determine if there are any metals present in the product that are not supposed to be there.

In the food industry, it is important to ensure that the food you are selling is safe for consumption. This can be difficult when you have a high volume of products to inspect. The ferrous non ferrous metal detector is a device that detects the presence of metal in your product. It works by emitting magnetic fields and measuring their effects on surrounding objects. If no effect is detected, then there is no metal present.

The ferrous non ferrous metal detector can be used in many different areas of the food industry including:

-Bakery

-Meat processing

-Dairy processing

-Seafood processing

A ferrous non ferrous metal detector is a device that can be used to check food products for the presence of metal. The device works by sending an electrical current through the product, which causes the metal to react and produce an electromagnetic field. This field can then be detected by the detector and analyzed to determine whether it contains any metal.

A belt metal detector is usually used in conjunction with a ferrous non ferrous metal detector as part of a system designed to inspect food products before they are packaged or sold. This type of system can be used in a variety of ways, including:

-To detect if there are any pieces of metal in a product (for example, if someone has accidentally dropped a screw inside)

-To detect whether there are any insects inside food containers (for example, if there are ants hiding inside apple slices)

-To ensure that all food packaging is sealed properly so nothing leaks out during transit

ferrous materials metal detector

1. Widely used for small or large-sized bulk and packaged food, medicine product lines, and other purposes. You can use it for frozen dumplings, meatballs and aquatic products. It also works well with sanitary napkins, chafing material and prepared food.

2. The machine is equipped with a learning function that allows it to automatically indentify different detection products, so it can try to minimize the material effect.

3. We can custom design different sizes and reject systems based on the products and lines.

4. Suitable for wet, dry, dusty, dew environment, made from stainless steal, has HACCP attestation, and waterproof IP65

ferrous materials metal detector Key Benefits

Prevents metal contaminants from going undiscovered in products

Multiple product rejection options are available

Hygienic Conveyor Belt

There are many options for belt sizes and configurations

Variable Speed

Conveyors that can inline or decline

Can be used for all food processing or non-food applications

Detected products Height | 80 | 120 | 80 | 100 | 120 | 150 | 200 |

Detected products Width | 300 | 300 | 400 | 400 | 400 | 400 | 400 |

Belt Width | 250 | 250 | 350 | 350 | 350 | 350 | 350 |

Belt length | 1500 | ||||||

Detector sensitivity | Feф0.5 | FeФ0.8 | FeФ0.6 | FeФ0.7 | FeФ0.8 | FeФ0.8 | FeФ1.0 |

SUSф1.0 | SUSФ1.5 | SUSФ1.0 | SUSФ1.2 | SUSФ1.5 | SUSФ2.0 | SUSФ2.3 | |

N-Feф0.8 | N-FeФ1.0 | N-FeФ0.8 | N-FeФ1.0 | N-FeФ1.2 | N-FeФ1.5 | N-FeФ1.5 | |

Speed of belt | 27M/min (can adjust 5-40 M/min) | ||||||

Load ability | 20KG | ||||||

Count | 100 | ||||||

Reject Ways | Sound and light alarm with belt stoped ;(when has auto-reject system ,belt continue and rejecting the goods ) | ||||||

Application | Non-package ,plastic package ,paper bag or box (non-metallic) product | ||||||

Work Environment | Temperature -10℃-40℃ ,relative humility 30-90% | ||||||

Technical details

Power supply: 100-240 V AC, 50/60Hz

Maximum power consumption Maximum power consumption: 50 W

Type of protection: IP66 (IP69 K).

Min. Minimum temperature of operation: -10 degC

Max. Max.

Relative humidity: 0 to 95 % (without condensation).

Max. Maximum speed of conveyor belts at which metals are reliably detected is 30 m/s

Power cable: 1.8m with plug