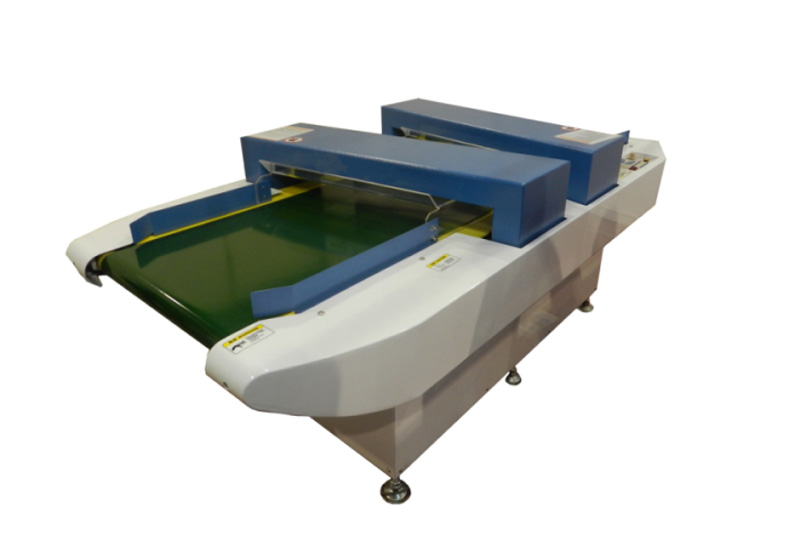

60*10 size Metal Detector Machine for Garment Industry

Quality solution metal detector machine for garment

A metal detector machine is a quality control solution designed to ensure the safety and quality of garments by detecting the presence of metal contaminants. These metal contaminants can come from a variety of sources, including metal buttons, zippers, or other metallic accessories used in the manufacturing process.

Advance technology of metal detector for garment

The metal detector machine for the garment industry uses advanced technology to detect the presence of metal contaminants in garments. The system consists of a conveyor belt that transports the garments through a detection chamber equipped with specialized sensors. These sensors use electromagnetic technology to detect the presence of metal contaminants within the garment, even at extremely low levels.

If a metal contaminant is detected, the metal detector machine will trigger an alarm and automatically stop the production line, alerting the operator to take corrective action. The system can also be programmed to sort contaminated garments from uncontaminated ones, ensuring that only safe and high-quality garments are released into the market.

Metal detector machines are an essential quality control solution for the garment industry, ensuring that garments meet the highest safety standards and comply with regulatory requirements. They can be used in a variety of garment manufacturing applications, including the production of shirts, pants, dresses, and other apparel.

Overall, a metal detector machine is an effective and efficient quality control solution for the garment industry, ensuring that garments are safe, high-quality, and free from metal contaminants.

A metal detector machine for the garment industry is a specialized quality control solution that ensures that garments are free from metal contaminants. These metal contaminants can come from various sources such as zippers, buttons, or other metal components used in the manufacturing process. The metal detector machine is designed to detect these contaminants and prevent them from reaching the market, thus improving the quality of the garments.

The metal detector machine for the garment industry typically consists of a conveyor belt that moves garments through a detection chamber equipped with advanced sensors. The sensors use electromagnetic technology to detect the presence of metal contaminants in garments, even at extremely low levels. If a metal contaminant is detected, the machine will trigger an alarm and automatically stop the production line, alerting the operator to take corrective action.

The metal detector machine for the garment industry is highly sensitive and can detect even the smallest metal fragments in garments, ensuring that only high-quality, safe products are released into the market. It is also highly reliable, with a low rate of false alarms, reducing the need for manual inspections and increasing production efficiency.

The metal detector machine can be customized to meet the specific needs of the garment industry, with different sizes and configurations available to suit various production requirements. It is easy to integrate into existing production lines, reducing downtime and minimizing disruption to the manufacturing process.

In conclusion, the metal detector machine for the garment industry is a valuable quality control solution that ensures that garments meet the highest safety and quality standards. It can significantly reduce the risk of product recalls and help companies maintain their reputation for producing high-quality products.