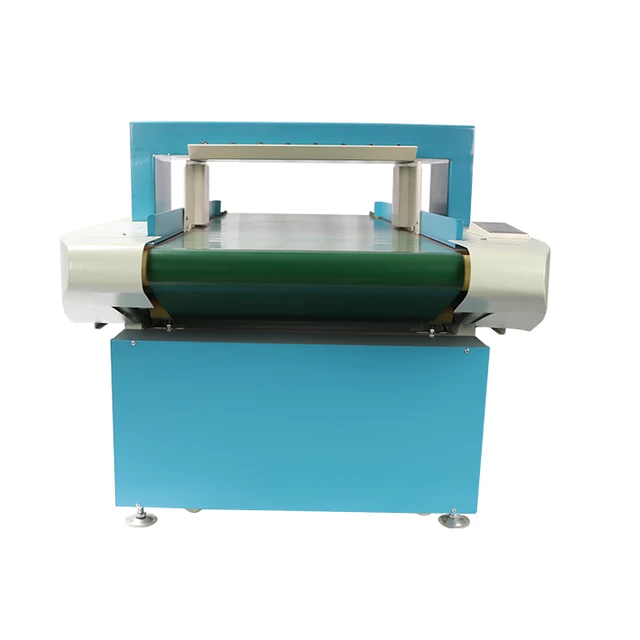

Garment Metal Detector at Best Price

Metal detectors are used to detect needles in garments and apparel. It is essential to ensure that all apparel and garments exported or sold are free of any metal contaminants. Exporting garments with needles or other undesirable metal articles can lead to lawsuits against the manufacturing company, as well as bad publicity and financial losses. Garment companies will invest in metal needle detection devices to thoroughly inspect garments for any metal contamination.

The garment manufacturers that produce clothing for children and babies need to have needle detection. Exporting apparel to Japan requires extra caution as Japan emphasizes the importance that all apparel imported must undergo metal and needle detection.

Now in walmart aduit system,FCCA request all garment ,toys,textile,shoes supplier must pass needle detector inspection before enter into walmart market

Then it is a import machine for all these manufacture that have to pass through their auidt systems

| MAXVFG-700S/D/Automatic Necess Dater |

| 1.Suits garment, food medicine industrials etc 2.32bit RICS, accurately detect and report 3.Flexible touch screen operation |

| Schedule of Specifications |

| ModelVFG-700S Anti-jamming single detectorVFG-700D Anti-jamming double detectorSensitivity detection600mm(W)x100mm-200mm(L)Detecting methodFe /C0.8mmx1.2mm(VFG-700s/VFG-700D)Operating methodMagnetic inductio-Touch typeHeight measurement<=120mmalarmLuminotron postition indicator, Hummer alarm. Stop or return conveyor beltDate outputSelect Chinese or English to print the detected report (detection day,detection status qualified,checkout and amount)Power requirementsAC220V +- 10% (50-60Hz)Power consumption100WPacking size1910x1140x1080mm2320x1140x1080mmBW/GW220/280Kg240/340Kg |