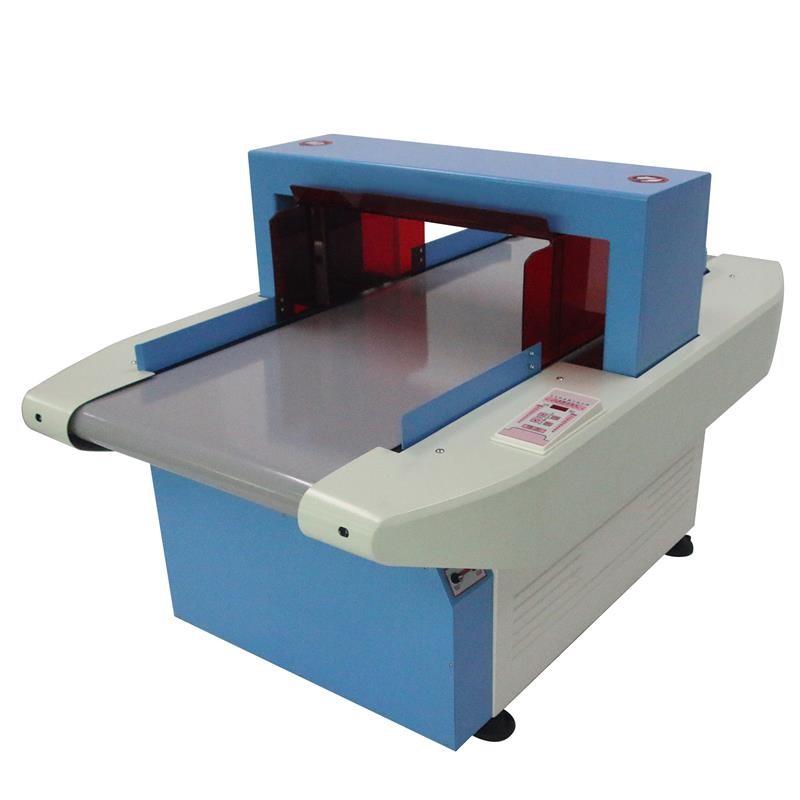

garment metal detector for cloth industry

Quality control garment metal detector for cloth processing

Important tool for garment and colthing industry

The garment metal detector is the most important tool for cloth industry.

It can detect the metal in garments, especially in garments with a lot of metal content.

This type of detector is used to find and remove metal from cloth products.

The garment metal detector can detect the metals such as copper, nickel, zinc, aluminum and iron etc.

Metal detector for garment processing industry

Metal detectors are a key component of any garment-manufacturing process.

They can detect the presence of metal objects in the production area, which can be a safety hazard for workers.

Metal detectors are also used to ensure that garments are not being sold with hidden defects.

The presence of metal on a garment can indicate that it has been altered after being made, which can lead to lawsuits and other legal concerns.

Implementing garment metal detectors in the cloth industry is essential for quality control and ensuring that finished garments are free from metal contaminants. Let's explore the significance, benefits, and key considerations associated with using metal detectors in the cloth manufacturing process:

## I. Importance of Garment Metal Detectors in the Cloth Industry

### A. Quality Assurance

1. **Preventing Contamination:** Metal detectors help prevent contamination of garments by identifying and removing metal contaminants introduced during the manufacturing process.

2. **Maintaining Product Integrity:** Ensuring that the final garments meet quality standards and do not pose risks to consumers due to metal contamination.

### B. Compliance and Safety

1. **Regulatory Compliance:** Meeting industry standards and regulations for product safety and consumer protection.

2. **Avoiding Recalls:** Metal detection helps avoid product recalls, protecting the brand reputation and ensuring compliance with safety guidelines.

## II. Key Stages for Garment Metal Detection in the Cloth Manufacturing Process

### A. Fabric Inspection

1. **Incoming Fabrics:** Metal detectors are employed to inspect rolls of fabric for any metal contaminants before they are used in the manufacturing process.

2. **Contaminant Rejection:** Automatic rejection systems can be integrated to remove contaminated fabric rolls, preventing them from entering production.

### B. Cutting and Sewing

1. **Inline Inspection:** Metal detectors can be integrated into the cutting and sewing lines to inspect garments for any metal particles introduced during the manufacturing process.

2. **Quick Rejection Systems:** Fast-acting rejection systems ensure that contaminated garments are immediately removed from the production line.

### C. Final Inspection

1. **Quality Control Check:** Metal detection is crucial during the final inspection before garments are packaged for distribution.

2. **End-of-Line Inspection:** Ensuring that metal contaminants are not present in finished garments before they reach consumers.

## III. Benefits of Garment Metal Detection in the Cloth Industry

### A. Consumer Safety

1. **Product Safety:** Prioritizing the safety of consumers by eliminating the risk of metal contamination in garments.

2. **Avoiding Injuries:** Preventing potential injuries or discomfort associated with wearing garments that contain metal contaminants.

### B. Operational Efficiency

1. **Reduced Downtime:** Early detection of metal contaminants helps prevent equipment damage, reducing downtime and minimizing disruptions in the production process.

2. **Enhanced Production Speed:** Ensuring a smooth production process by quickly identifying and eliminating metal contaminants without compromising production speed.

### C. Compliance and Reputation

1. **Regulatory Compliance:** Meeting regulatory requirements and industry standards, avoiding fines, and ensuring continued market access.

2. **Maintaining Brand Reputation:** Upholding the reputation of the clothing brand by delivering safe and high-quality garments to consumers.

## IV. Implementing an Effective Garment Metal Detection System

### A. Choosing Appropriate Equipment

1. **Type of Metal Detector:** Selecting the right type of metal detector based on the specific needs of the cloth manufacturing process, such as conveyor-based detectors or handheld detectors for smaller items.

2. **Sensitivity Levels:** Configuring the sensitivity levels of the metal detector to detect both ferrous and non-ferrous metals at the required thresholds.

### B. Integration with Production Line

1. **Strategic Placement:** Installing metal detectors at strategic points along the production line to ensure thorough inspection.

2. **Integration with Conveyors:** Seamlessly integrating metal detectors with conveyor systems for efficient and continuous inspection.

### C. Regular Maintenance and Calibration

1. **Routine Checks:** Conducting routine checks, maintenance, and calibration of metal detection equipment to ensure optimal performance.

2. **Employee Training:** Training personnel on the proper use and maintenance of metal detection systems to maximize effectiveness.

## V. Conclusion

In the cloth industry, garment metal detectors play a pivotal role in ensuring product safety, compliance with regulations, and the maintenance of brand reputation. By implementing robust metal detection systems at various stages of the manufacturing process, clothing manufacturers can minimize the risk of metal contamination and deliver high-quality garments to consumers. Regular maintenance, proper training, and the selection of suitable metal detection equipment are key factors in achieving a successful and effective metal detection program in the cloth industry.

Viking garment metal detector for cloth industry

The Viking garment metal detector for cloth industry is the most advanced metal detector in its class.

It has been designed to be versatile, reliable, and cost-effective. The machine uses a computerized system with

an advanced processor to scan for metal objects and report the results. This allows you to scan large amounts

of material quickly and easily, which is vital for businesses operating in a cost-conscious environment.

The Viking garment metal detector for cloth industry features four scanning modes:

- Continuous Scan Mode - this mode scans continuously while you are moving the machine around your work area. It will continue scanning until it has scanned every square inch of your work area.

- Area Scan Mode - this mode scans one section of your material at a time. You can then take a picture of each sheet or roll with your smartphone or tablet so that you can review each item before it goes out on the floor.

- Single Pass Mode - this mode scans only one square inch of your material at a time, which allows you to quickly locate any areas that may contain hidden pockets or pockets that are empty but appear full due to shadows caused by overhead lights overhead or other factors (such as dust on clothing).