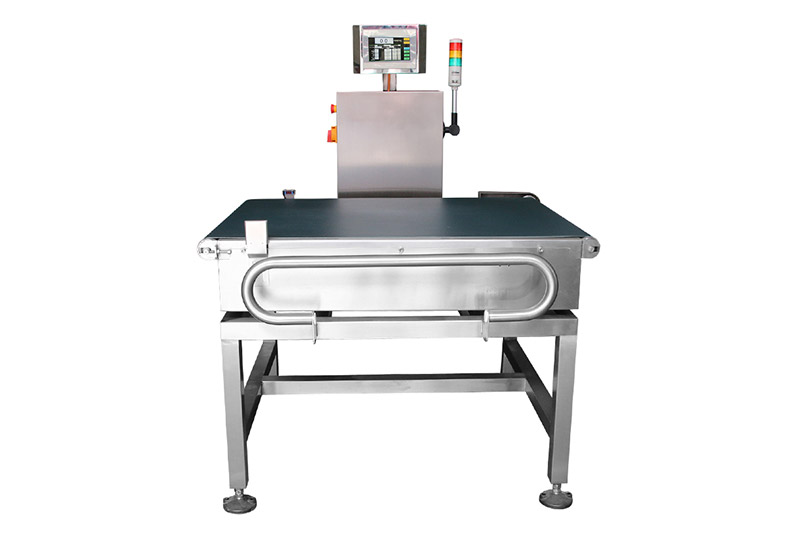

washdown checkweigher

What is a Washdown Checkweigher?

A washdown checkweigher is a type of checkweighing machine that is designed to withstand the harsh conditions of food processing environments. It is used to weigh and sort products based on weight to ensure that they meet specific quality control standards. The washdown checkweigher is typically used in food processing plants where products need to be washed down frequently to maintain hygiene and prevent contamination.

How Does a Washdown Checkweigher Work?

A washdown checkweigher works by weighing products as they pass through the machine. The products are placed on a conveyor belt and move through the weighing area. The weighing area consists of load cells that measure the weight of the product. The weight is compared to a pre-set target weight, and if the weight is within the acceptable range, the product continues on its path. If the weight is outside of the acceptable range, the product is rejected and diverted to a reject station.

Key Features of a Washdown Checkweigher

Stainless Steel Construction: The washdown checkweigher is typically made from stainless steel, which is resistant to corrosion and can withstand harsh cleaning chemicals.

IP Rated: The washdown checkweigher has a high IP rating, which means it is protected against dust and water ingress.

High Accuracy: The washdown checkweigher is designed to provide accurate and consistent weighing results, even in challenging food processing environments.

Easy to Clean: The washdown checkweigher is designed to be easy to clean, with smooth surfaces and minimal crevices where bacteria can accumulate.

Customizable: The washdown checkweigher can be customized to meet specific production requirements, such as different product sizes, weights, and speeds.

Benefits of a Washdown Checkweigher

Quality Control: The washdown checkweigher is a crucial component in quality control processes in food processing plants. It ensures that products meet specific weight requirements and are of consistent quality.

Increased Efficiency: The washdown checkweigher can improve production efficiency by reducing waste and optimizing the sorting and weighing process.

Compliance: The washdown checkweigher helps food processing plants comply with industry regulations and food safety standards.

Reduced Costs: The washdown checkweigher can help reduce costs by minimizing waste, optimizing production processes, and reducing the risk of product recalls.

Considerations When Choosing a Washdown Checkweigher

Production Requirements: Consider the production requirements, such as product sizes, weights, and speeds, when choosing a washdown checkweigher.

Hygiene Requirements: Consider the hygiene requirements of the food processing plant and choose a washdown checkweigher that is easy to clean and sanitize.

Compliance: Ensure that the washdown checkweigher complies with industry regulations and food safety standards.

Integration: Consider how the washdown checkweigher will integrate with other production processes and equipment.

Conclusion

In conclusion, a washdown checkweigher is a crucial component in food processing plants that ensures product quality and compliance with food safety standards. Its key features, such as stainless steel construction, high accuracy, and easy cleaning, make it an essential tool for the food processing industry. When choosing a washdown checkweigher, it is important to consider production and hygiene requirements, compliance, and integration with other equipment.