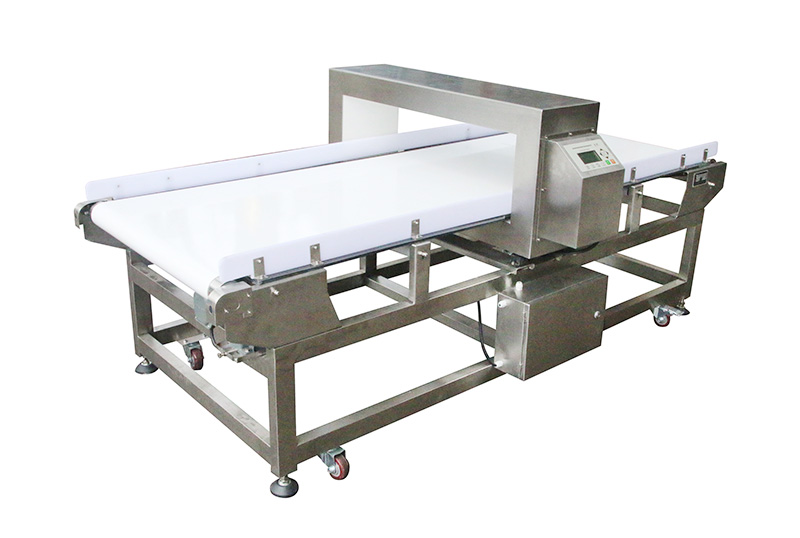

metal detector for plastic pellets

Conveyor belt metal detector for plastic pallet

What is a plastic pallet?

A plastic pallet is a type of pallet that is made out of plastic.

It comes in different shapes and sizes, depending on the industry it's used in.

A plastic pallet is often used when transporting goods by ship or plane, but you can also find them used in warehouses and distribution centers.

The main advantage of using a plastic pallet over other types is that they are lightweight and durable.

They also come in different sizes, which means that you can use them for different sized goods without having to make multiple trips back and forth between different warehouses or distribution centers.

What it is a critical step of metal detection during plastic pallet processing ?

Metal detection is a critical step in plastic pallet processing, as it helps you ensure that only safe materials are added to the pallet.

Without metal detection, you may be adding harmful metals that could contaminate your production line.

Wide range metal detector for plastic processing industry

Metal detection system for plastic pellets processing industrial

We offer the metal detection system for plastic pellets processing industrial. It is a kind of high-tech equipment which is used to detect the metal of the raw material and then, it will automatically control the process. The device can be used in various plastic materials processing line, such as plastic pellet production, extrusion, injection molding, extrusion blow molding, etc.

metal detection system for plastic pellets

The metal detection system for plastic pellets processing industrial is used to monitor the incoming traffic of plastic pellets.

The system can be installed in different locations, such as entrance gates and loading platforms. It can be used to detect the presence of metal objects in plastic pellets, which can cause accidents or damage to equipment.

The metal detection system for plastic pellets processing industrial includes:

- A sensor that detects the presence of a metal object in the plastic pellets.

- A controller that controls the operation of the sensor based on its detection signal.

- An alarm panel that alerts operators when there is a problem with the system's operation.

The most critical step of metal detection during plastic pallet processing is the determination of the presence or absence of a metal plate. This can be done by using a metal detector and then comparing the results with what was expected based on the type of plastics being used.

If there are no metals present, then this is considered good news for the manufacturer who is trying to process their plastic pallets into something else like a roll of wrapping paper or a box. If there are metals present, then this means that there was something wrong with how they were made and should be disposed of immediately rather than recycled into another product.