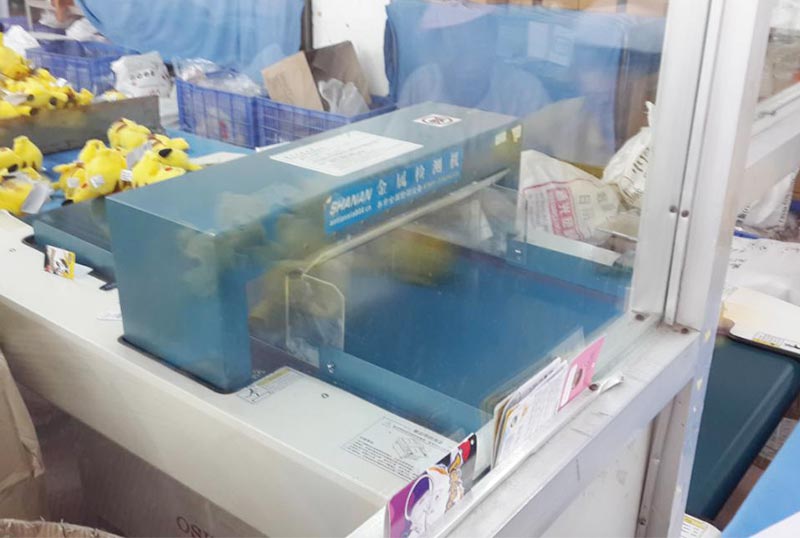

High sensitivity wide tunnel metal detector for textile industry

wide range search head metal detector for food or textile industrial

1. head search metal detector Application

This machine is used for clothing, feather products (toys), shoes, socks, food, medicines, and other products seized iron needles. Tested the decorative effect of the demagnetization in clothing, toys’metal decorations, zippers, buttons and so on.

2. Notes

Metal ornament buttons, zippers, etc. must be strictly demagnetization before sewing, or it will affect the normal detection.

a)

When sewing using needles, pins, and other steel products, please be sure to use magnetic substance. Pure stainless steel, aluminum, copper or plastic, and other non-magnetic metals will not be detected.

head search metal detector Specifications

once the subject is placed on the conveyor belt to be sent to the detection part,it will detect whether needle or iron and other substances. Once found, the conveyor automatically stops, alarms, and automatically backward.

not only can be checked one by one, but bundled and packaged (nylon film bag) can also be in a good check.

Because the inspection unit is bridge channelized, according to the thickness (height) of the item examination, the degrees that can be checked are different. Manufacturers refer to the Japanese proposal, the international standard produced by the record.

The wide-range search head metal detector is a new kind of metal detector that is developed to help detect nonferrous metals in food or textile industries. The device has an LCD display, which shows the statistics of the detection results. It also has an easy-to-read control panel, which allows users to easily adjust the settings and perform other operations on their own. The wide-range search head metal detector is designed for industrial use, and it can be used at any point during production lines or in storage areas.

1. Select and pay attention to the using place

1.1 Vibration resistance

Select an indoor vibration-free place, preferably a flat concrete floor, a terrazzo floor is the best choice.

1.2 Effect of metal products on the machine

Within a meter from the detection portion, do not pile up metal tables, chairs, boxes, shelves, and so on. Motion sewing machines, cutting machines, and loading machines must to move more than four meters away.

1.3 Radio barriers

The top of the needle detector can not install the power-operated machine such as ceiling fans. High-voltage transformers and high-frequency packaging machines could easily generate strong electromagnetic fields, they must to move more than 10 meters away. Also, avoid cars, and trams constantly passing the roadside and so on.

1.4 Ambient conditions

Please put the machine in a small change in temperature and humidity, as well as a place with minimal dust.

1.5 Effect of other items

The detecting portion generates a strong magnetic, so watches, VCD cards, credit cards, driver's licenses, BP machines, mobile phones, and other items susceptible to magnetic influence, never close.

2. power usage

The instrument uses a single-phase power supply of 220V ± 10V 50HZ, please equipped with a single-phase socket with a grounding device, regularly check whether the connection portions contact is good or not, to prevent poor contact factors caused such as motors, electrical systems elements burned.

3. Moving note

Once the machine is installed, try not to move. If the machine needs to be replaced (in the case of last resort), Please operate properly. When the horizontal movement for a short distance, first put down four adjustment bolts M16 nut, make the caster off the ground, and adjust the level. Long-distance moves must be fixed in the flat or moving vehicles.

Note: Do not move when pushed, pull the main driven shaft.

4. Fixation

Fixed on a flat concrete floor, use the adjusting screw, to move in the direction of four small wheels 0.5-1.5 cm from the ground, and then correct level, otherwise it will be easily lead to the phenomenon of belt deviation and false alarms.

Methods of use of the machine

Operational staff are forbidden to wear ties, and scarves when operating, ladies with long hair must fix the hairs in the work hat, prohibited from hanging, and forbidden to wear watches and metal jewelry.

2. Plug in the power, plug, You must use a 220V special socket with a grounding device.

3. Press the red power switch (right angle on the electric box). Watch the red signal lights, and check whether the power contact is good or not, no leaping twinkling, indicating good contact.

4.。After the power is turned on, the power and indicator lights light up, at the same time after each operation indicator flashes three times on the panel, the display shows the current time and enters the standby state.

5. Check if the sensitivity of the gear indicator is suitable for general inspection routine stalls at 8, 9 files, such as special needs again to 0--7 file or 10 files. Non-inspectors are not free to change gear.

6. Press the start / stop button, and the machine instantly operates normally. Press the Start / Stop button again, it will stop.

7. equipment is operating properly, 2-second delay time (to extend the life of equipment, and reduce the current impact, it set the delay time), the standard detection block used with the supplied onto the conveyor belt testing, inspection equipment testing performance, Repeat 2-3 times, and check the automatic rewind distance is in an ideal position. For adjustment, see: Setting 5,2 rewind time.

8. After check the performance is normal, please place the ordered check items on the conveyor belt and start to detect.

The item should be

lighter to place on the conveyor belt, with no throwing or place heavy.

。If the detected item is detected to have foreign matter, it will sound and light an alarm, the automatic conveyor stop rewinding, the operator will remove the item, then does not need to start, and the machine will automatically run, continue detection (in automatic function selected case).

· Also note that items removed after being detected, should find out the magnetic substance (needle), and then repeat inspection once again, to prevent multiple needles and missed.

After testing, or after work, press the start/stop button, turn off the power switch, and unplug the power cord. Do the cleaning work, cover the covers or nylon hood.

· Standard test block must be safekeeping.

一. How to avoid false alarms and correct analytical processing

1.1. To use the needle detector better

1.2. The responsible person should guide the correct methods to the operator, and be familiar with these instructions.

1.3. The needle must be steel products.

1.4. Finding the needles when sewing, be sure to find out before replacing the new needle, do not relax the system.

1.5. For Decorative (including buttons, and zippers) metal products, be sure to thoroughly demagnetize (demagnetization) before sewing up

1. If there is no needle or iron sheet whether it will alarm?

3.1.

3.2. 。

2.1 without the demagnetization (demagnetized) or despite demagnetization (demagnetization) but demagnetization (demagnetization) entirely of metal buttons, zippers dense arrangement, also will be checking out and alarm.

2.2. Scissors (including machine knife) After sharpening iron powder, color chalk stick on clothes, which can also be detected and alarm, so after use the cutting blade sharpening, pay special attention to the handle clean.

2.3 Tainted with oil’s detected item, readily adsorbed metal powder, it will be detected and alarmed.

2.4. The end of the stick metal rust on an inspection was also detected and alarm.

2.5. Dark dye with iron, dyed cloth with iron, also can be detected alarm,shall indicate before it is sent to dye cloth.

2. Check, protection

3.1 The equipment is functioning, check if there are floating look shift phenomenon, if only to illustrate the four adjustment bolts loose foot, the fixed re-adjust the horizontal.

3.2 within four meters around the instrument whether the metal in motion.

3.3 Rotating part-load inspection, shafts, etc. are unusual sounds, if any, with a clean cloth or towel to wipe clean the bearing, adjust the bolt and then through the shaft drop 2-3 drops of sewing machine oil.

3.4 whether the performance is unstable, the sensitivity indicator flash jump phenomenon, may cause serious false alarms,

3.5please check off the power after checking the load:

Check the upper and lower surfaces of the channel poked for metal adsorption, and squeeze carefully with a clean towel after wiping clean and water damage.

3.6 There is no dirt metal sheets, or powder, if still not found significant objects, use a clean wet towel carefully to both the positive and negative two faces repeatedly several times to wipe the inspection conveyor belt! Note that after carrying off the power!

access key parameter setting method function

press the set button, the screen will be small, select a digital rewind time after a tap, a set screen appears, press the rewind to choose a good time, such as "1.8" after the point after entering completing the set rewind time, then after the detection of the digital standard, the same operation as above, to complete the setup, press the Escape key, complete functions of the machine settings.

Machine parameter settings, the machine has automatic and manual controls, tap the screen to select automatic and manual, and the same text appears. In automatic mode, the machine after detecting the metallic foreign body can automatically stop and restart automatically after the return, the manual mode, the machine detects the metallic foreign body after the alarm to go back and stop, but does not start automatically, you need to press the start button.

For sensitivity adjustment, press the up arrow to indicate increased sensitivity at the same time indicating light beams were lit up, each click level rise, and a corresponding digital display (0-10). Press the down arrow indicates decreased sensitivity down lights were turned off at the same time, 10 being the highest sensitivity, and 0 being the lowest.

Select book material and thick material features, as long as the tap button, you can easily switch, thin material is without an infrared-assisted detection method, and thick material is required to detect infrared photoelectric ancillary way. This machine is turned on by default in workbook material mode.

5、

Setting printing: the printer taps the screen, and the screen will appear in two options boxes (at noon and in English) choose their printing language by what the test results printed out. (Optional)

6、

Press the OFF OFF button while the screen is converted into the ON button to start the machine, and press the ON button to stop the machine.

7、

Tap the screen qualified key will show "qualified" "detection", "and total", the above figures will be randomly recorded show.

8、

Clearing counts: In standby mode at a set point key, small screen, tap the "Clear Count" to complete the clear, and press the Escape key.

9、

When items, certain items from the front of the machine and gently placed to ensure proper detection machine can not detect the product to throw up bad operating habits!

10、

Position display can accurately show the approximate location of the needle (the on-screen beam (0-9) to facilitate workers can quickly use a small hand-held needle detector to find the break.

11、

Function display can clearly visually display the working status of the machine.

12、

Each machine factory has standard test blocks and various instruments strict debugging, so we should be based on standard test block test machine standards to industry standards as the standard, the machine can be a fair judge good or bad!

13、

Each time you use it, should first try to use the standard test block a few times, to see whether the machine is properly to ensure quality testing.