Tunnel metal detector for conveyor and production line

Tunnel metal detector for conveyor and production line

We offer a wide range of tunnel metal detectors that are designed specifically for the requirements of your production line, including:

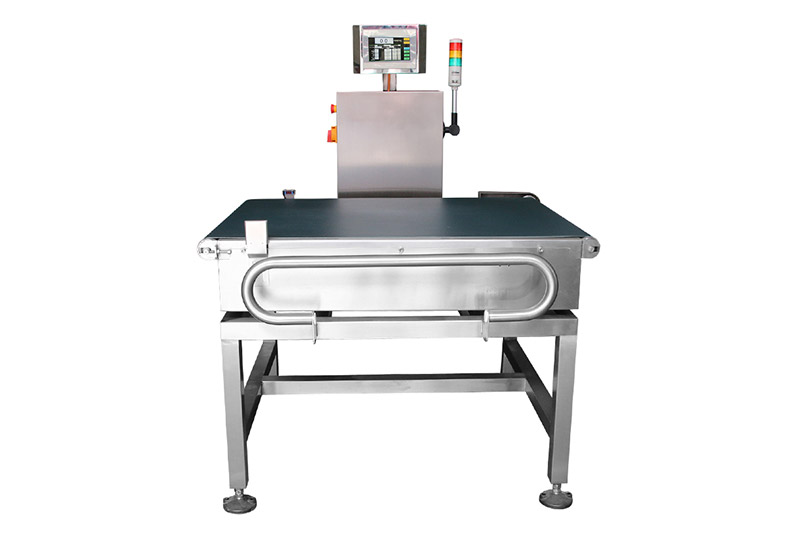

-Tunnel metal detectors with an integrated conveyor belt (conveyor-mounted)

-Tunnel metal detectors with an integrated conveyor belt (conveyor-free)

-Tunnel metal detectors without an integrated conveyor belt

Conveyor and production line metal detectors

are used to detect foreign objects that may be present in the product. These objects can include nuts, bolts, nails, staples and other fasteners.

There are two primary types of conveyor metal detectors:

-Passive Metal Detectors: These are typically used for paper and plastic applications. They use a magnetic field to detect ferrous or magnetic materials. The advantage of passive metal detectors is that they do not require power to operate so they can be used in environments where electrical power is not available or where there is a potential for electrical interference from other processes such as conveyor belt movement. They also produce less heat than active systems which helps reduce the risk of fire if there is an electrical failure within the equipment being inspected.

-Active Metal Detectors: These are typically used for metals such as aluminum cans and iron parts that do not contain iron oxide (rust). Active systems employ direct current (DC) magnetism rather than alternating current (AC) magnetism which means they are more sensitive than passive systems but require power to operate. In addition, active systems produce more heat than